Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Can Solderer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

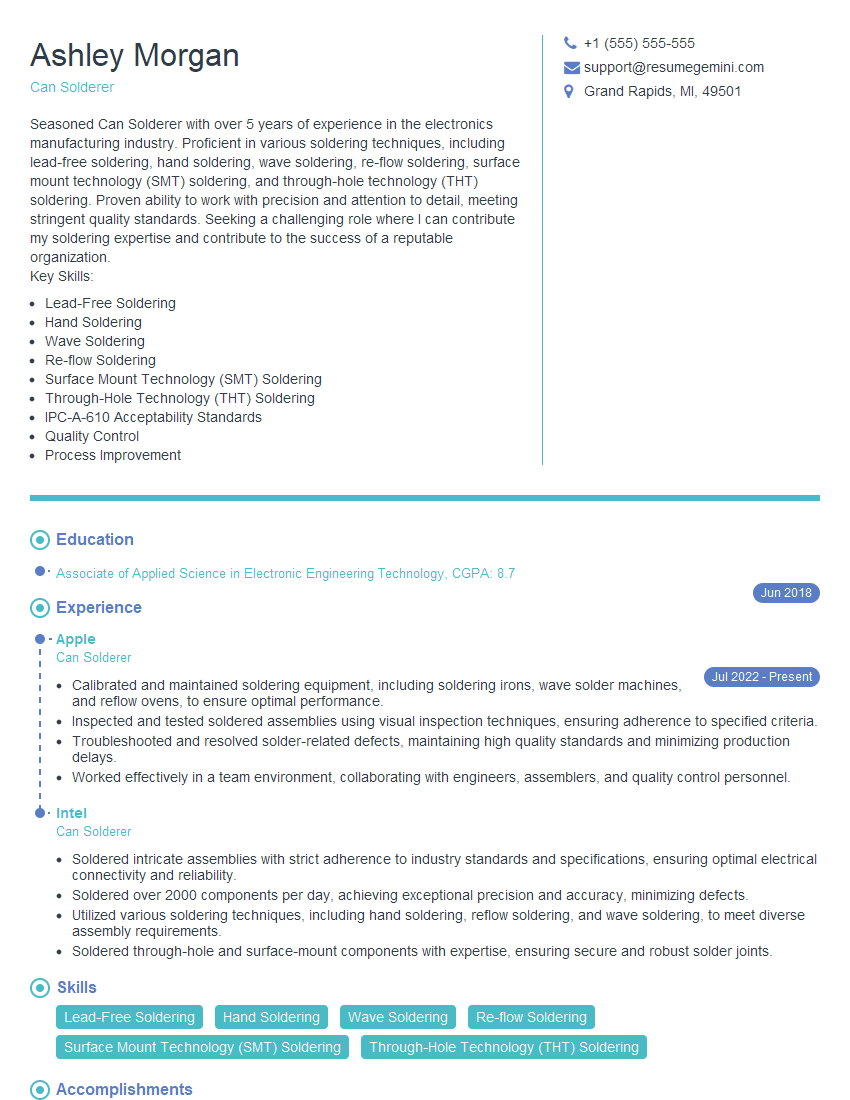

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Can Solderer

1. What are the different types of soldering techniques? How do you choose which technique to use on a particular job?

There are three main types of soldering techniques:

- Hand soldering: This is the most common type of soldering, and it is done by hand using a soldering iron and solder.

- Wave soldering: This type of soldering uses a wave of molten solder to solder components to a circuit board.

- Reflow soldering: This type of soldering uses heat to melt solder paste that has been applied to a circuit board, and it is then used to solder components to the board.

The type of soldering technique that is best for a particular job depends on a number of factors, including the size and complexity of the circuit board, the number of components that need to be soldered, and the desired quality of the finished product.

2. What are the different types of solder? How do you choose which type of solder to use on a particular job?

There are many different types of solder, each with its own unique properties. The most common types of solder are:

- Lead-based solder: This type of solder is made from a combination of lead and tin.

- Lead-free solder: This type of solder does not contain any lead.

The type of solder that is best for a particular job depends on a number of factors, including the type of metal that is being soldered, the desired strength of the joint, and the environmental regulations in the area where the soldering is being done.

3. What are the different types of soldering fluxes? How do you choose which type of flux to use on a particular job?

Soldering fluxes are used to clean the surfaces of the metal that is being soldered, and to promote the flow of solder. There are many different types of soldering fluxes, each with its own unique properties. The most common types of soldering fluxes are:

- Rosin-based flux: This type of flux is made from a combination of rosin and alcohol.

- Acid-based flux: This type of flux is made from a combination of an acid and a solvent.

The type of soldering flux that is best for a particular job depends on a number of factors, including the type of metal that is being soldered, the desired strength of the joint, and the environmental regulations in the area where the soldering is being done.

4. What are the different types of soldering irons? How do you choose which type of soldering iron to use on a particular job?

There are many different types of soldering irons, each with its own unique properties. The most common types of soldering irons are:

- Pencil-type soldering iron: This type of soldering iron is the most common type, and it is held in the hand like a pencil.

- Butane soldering iron: This type of soldering iron is powered by butane gas, and it is often used for field work.

- Induction soldering iron: This type of soldering iron is powered by induction heating, and it is often used for high-volume soldering applications.

The type of soldering iron that is best for a particular job depends on a number of factors, including the size and complexity of the circuit board, the number of components that need to be soldered, and the desired quality of the finished product.

5. What are the different types of soldering stations? How do you choose which type of soldering station to use on a particular job?

There are many different types of soldering stations, each with its own unique features. The most common types of soldering stations are:

- Basic soldering station: This type of soldering station includes a soldering iron and a temperature control unit.

- Advanced soldering station: This type of soldering station includes a soldering iron, a temperature control unit, and a number of other features, such as a fume extractor and a solder dispenser.

The type of soldering station that is best for a particular job depends on a number of factors, including the size and complexity of the circuit board, the number of components that need to be soldered, and the desired quality of the finished product.

6. What are the different types of soldering accessories? How do you choose which type of soldering accessory to use on a particular job?

There are many different types of soldering accessories, each with its own unique purpose. The most common types of soldering accessories are:

- Solder wick: This type of accessory is used to remove solder from a circuit board.

- Flux pen: This type of accessory is used to apply soldering flux to a circuit board.

- Soldering tip cleaner: This type of accessory is used to clean the tip of a soldering iron.

The type of soldering accessory that is best for a particular job depends on the type of soldering that is being done and the desired quality of the finished product.

7. What are the safety precautions that should be taken when soldering?

There are a number of safety precautions that should be taken when soldering, including:

- Wear appropriate safety gear, such as safety glasses, gloves, and a lab coat.

- Work in a well-ventilated area.

- Do not touch the hot tip of the soldering iron.

- Do not smoke or eat while soldering.

- Store soldering equipment properly.

By following these safety precautions, you can help to prevent accidents and injuries.

8. What are the troubleshooting tips for soldering?

There are a number of troubleshooting tips that can help to solve common soldering problems, including:

- If the solder is not flowing properly, try cleaning the tip of the soldering iron.

- If the solder is bridging between two components, try using a smaller gauge of solder.

- If the solder joint is not strong enough, try using a higher wattage soldering iron.

- If the solder joint is too cold, try preheating the circuit board before soldering.

By following these troubleshooting tips, you can help to ensure that your soldering joints are strong and reliable.

9. What are the industry standards for soldering?

There are a number of industry standards for soldering, including:

- IPC-610: This standard covers the requirements for printed board assemblies.

- IPC-7351: This standard covers the requirements for hand soldering.

- IPC-A-610: This standard covers the requirements for the acceptability of soldered electrical and electronic assemblies.

By following these industry standards, you can help to ensure that your soldering meets the highest quality standards.

10. What are the future trends in soldering?

There are a number of future trends in soldering, including:

- The use of lead-free solder.

- The use of automated soldering equipment.

- The development of new soldering techniques.

By keeping up with these future trends, you can help to ensure that your soldering skills are in demand in the years to come.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Can Solderer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Can Solderer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Can Solderers are responsible for skillfully and accurately connecting and assembling metal components using soldering techniques. They utilize specialized soldering equipment to ensure proper electrical conductivity and secure joints. Their expertise is essential in various industries, particularly electronics manufacturing and metalworking.

1. Solder Component Assembly

- Assemble and solder electronic components onto printed circuit boards (PCBs) or other substrates.

- Inspect solder joints to ensure proper connections and adherence to specifications.

- Troubleshoot and repair faulty or damaged solder joints.

2. Soldering Equipment Operation

- Operate and maintain soldering equipment, including soldering irons, soldering guns, and desoldering pumps.

- Select appropriate solder alloys, fluxes, and techniques based on materials and project requirements.

- Calibrate and maintain equipment to ensure optimal performance.

3. Electrical Testing and Documentation

- Perform electrical testing on soldered components to verify functionality and compliance with specifications.

- Document soldering processes, including materials used, techniques employed, and quality control measures.

- Maintain records and provide reports on solder joint integrity and equipment performance.

4. Quality Control and Inspection

- Adhere to established quality standards and procedures to ensure consistent and reliable solder joints.

- Inspect soldered assemblies for defects, contamination, or non-conformities.

- Implement corrective actions to improve solder joint quality.

Interview Tips

To help you ace your interview for a Can Solderer position, here are some essential interview preparation tips and tricks:

1. Research the Company and Industry

- Familiarize yourself with the company’s products, services, and industry.

- Research the specific role and its responsibilities within the organization.

- Understand the company’s core values and mission to align your answers accordingly.

2. Practice Your Soldering Skills

- Review basic soldering techniques and principles.

- Practice soldering on a sample PCB or other material to demonstrate your proficiency.

- Be prepared to discuss the different types of solders, fluxes, and equipment you have experience with.

3. Highlight Your Experience and Projects

- Quantify your experience by providing specific examples of projects you have worked on.

- Describe the techniques you used, the challenges you faced, and the results you achieved.

- Emphasize your ability to solder complex assemblies or handle delicate components.

4. Prepare for Technical Questions

- Review basic electrical concepts, such as resistance, voltage, and current.

- Be familiar with the different types of materials used in soldering, such as metals, plastics, and ceramics.

- Practice troubleshooting common soldering issues and discuss your approach to problem-solving.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Can Solderer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!