Are you gearing up for an interview for a Can Top Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Can Top Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

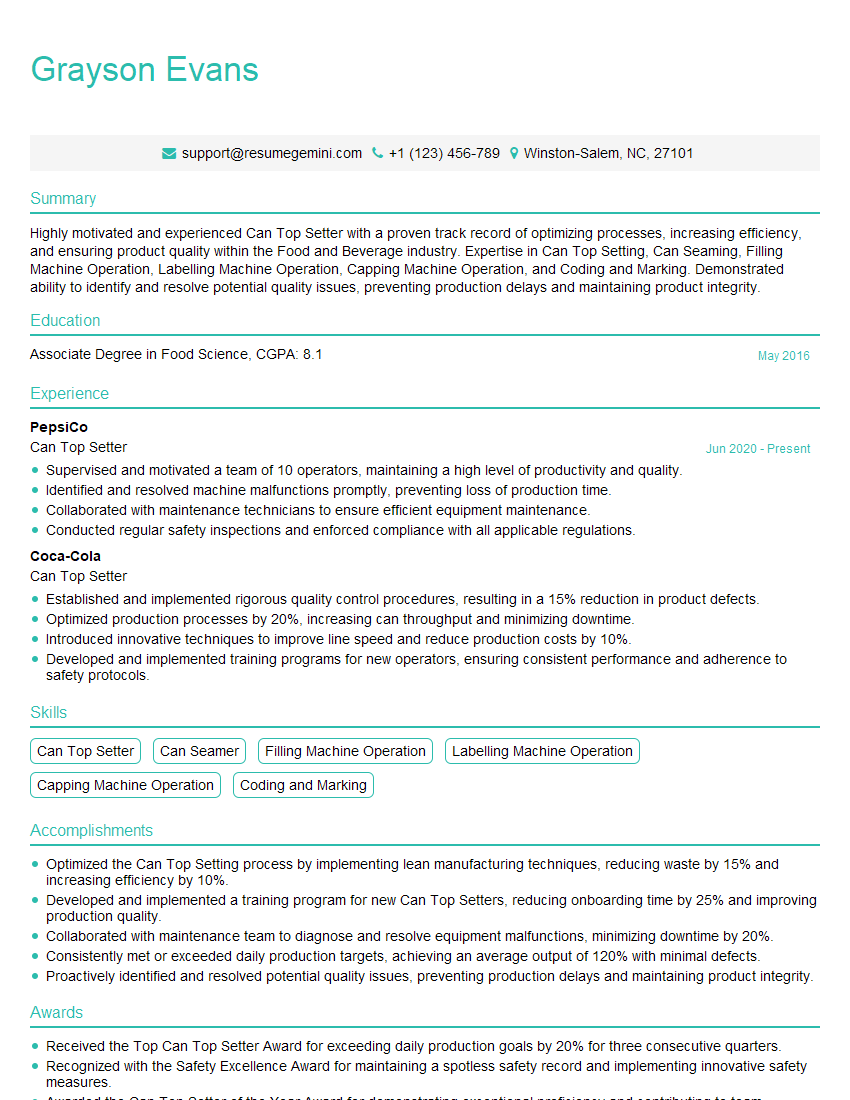

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Can Top Setter

1. What are the key responsibilities of a Can Top Setter?

- Operate and maintain can top setting machines

- Set up and adjust machines for different can sizes and products

- Inspect cans for defects and remove any damaged cans

- Monitor and control product quality

- Maintain a clean and safe work area

2. What are the different types of can top setting machines?

- Automatic can top setting machines

- Semi-automatic can top setting machines

- Manual can top setting machines

3. What are the factors that affect the quality of can top setting?

- Can size and shape

- Product type

- Machine settings

- Operator skill

4. What are the common problems that can occur during can top setting?

- Can jams

- Product leaks

- Can damage

- Machine breakdowns

5. How do you troubleshoot and repair can top setting machines?

- Identify the problem

- Determine the cause of the problem

- Repair or replace the damaged part

- Test the machine to ensure that it is working properly

6. What are the safety precautions that must be followed when operating a can top setting machine?

- Wear appropriate safety gear, including gloves, safety glasses, and a hairnet

- Keep hands away from moving parts

- Do not operate the machine if it is not properly guarded

- Report any safety hazards to your supervisor

7. What is the importance of quality control in can top setting?

Quality control is important in can top setting to ensure that the cans are properly sealed and that the product is not contaminated. A poorly sealed can can lead to product spoilage, which can be a health hazard. A contaminated product can also be a health hazard, and it can also damage the company’s reputation.

8. What are the different quality control checks that are performed during can top setting?

- Visual inspection of the cans

- Leak testing

- Weight checking

- Microbial testing

9. What are the different ways to improve the efficiency of a can top setting operation?

- Automate the process

- Use more efficient equipment

- Train operators on how to operate the equipment properly

- Implement a quality control program

10. What are the career advancement opportunities for a Can Top Setter?

- Supervisor

- Manager

- Quality control inspector

- Maintenance technician

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Can Top Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Can Top Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Can Top Setters are pivotal members of a production line, ensuring seamless operations by monitoring and adjusting machinery used to create can tops, which are essential components in the beverage industry.

1. Machine Monitoring and Adjustment

Constantly observe and monitor can top setting machinery to ensure optimal performance and identify potential issues.

- Track machine parameters, such as speed, temperature, and pressure, and adjust them as necessary to maintain efficient production.

- Identify and promptly address any irregularities or malfunctions in the equipment, preventing downtime and ensuring smooth operations.

2. Quality Control and Inspection

Meticulously inspect can tops to verify they meet the required specifications and quality standards.

- Perform visual inspections and use measuring devices to ensure dimensions, shapes, and finishes meet established criteria.

- Identify and segregate defective can tops, preventing them from entering the production process and compromising product quality.

3. Maintenance and Troubleshooting

Proactively perform routine maintenance tasks and troubleshoot issues to prevent breakdowns and ensure continuous operation.

- Clean and lubricate equipment regularly, following established maintenance schedules.

- Identify and resolve minor issues independently, minimizing downtime and maintaining productivity.

4. Record Keeping and Reporting

Maintain accurate records and provide periodic reports on machine performance, production output, and any issues encountered.

- Document all adjustments made to machinery, including dates, times, and reasons for changes.

- Communicate any production or quality issues to supervisors, enabling timely corrective actions.

Interview Tips

Preparing for a Can Top Setter interview requires a combination of technical knowledge and a strong understanding of the industry. Consider these tips to enhance your chances of success:

1. Research the Company and Role

Thoroughly research the company you’re applying to, its products, values, and the specific responsibilities of the Can Top Setter role. This demonstrates your interest and commitment to the position.

- Visit the company’s website, LinkedIn page, and industry news sources to gather information.

- Identify key performance indicators (KPIs) associated with the role and how you can contribute to them.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating and maintaining can top setting machinery. Quantify your accomplishments to demonstrate your impact on productivity and quality.

- Provide specific examples of how you identified and resolved machine issues, resulting in reduced downtime or improved output.

- Highlight your attention to detail and commitment to quality control, ensuring that can tops meet specifications.

3. Demonstrate Problem-Solving Abilities

Interviewers will assess your ability to troubleshoot and resolve issues effectively. Prepare examples that showcase your analytical thinking and problem-solving skills.

- Describe a situation where you encountered a complex machine issue and explain how you systematically diagnosed and resolved it.

- Emphasize your ability to think critically, identify root causes, and implement effective solutions.

4. Show Enthusiasm and Passion

Convey your enthusiasm for the can top setting process and the beverage industry. Express your interest in contributing to the company’s success and continuous improvement efforts.

- Share your knowledge of industry trends and how you stay updated on new technologies.

- Demonstrate your willingness to learn and grow within the role, expressing interest in career development opportunities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Can Top Setter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!