Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Candle Extrusion Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Candle Extrusion Machine Operator so you can tailor your answers to impress potential employers.

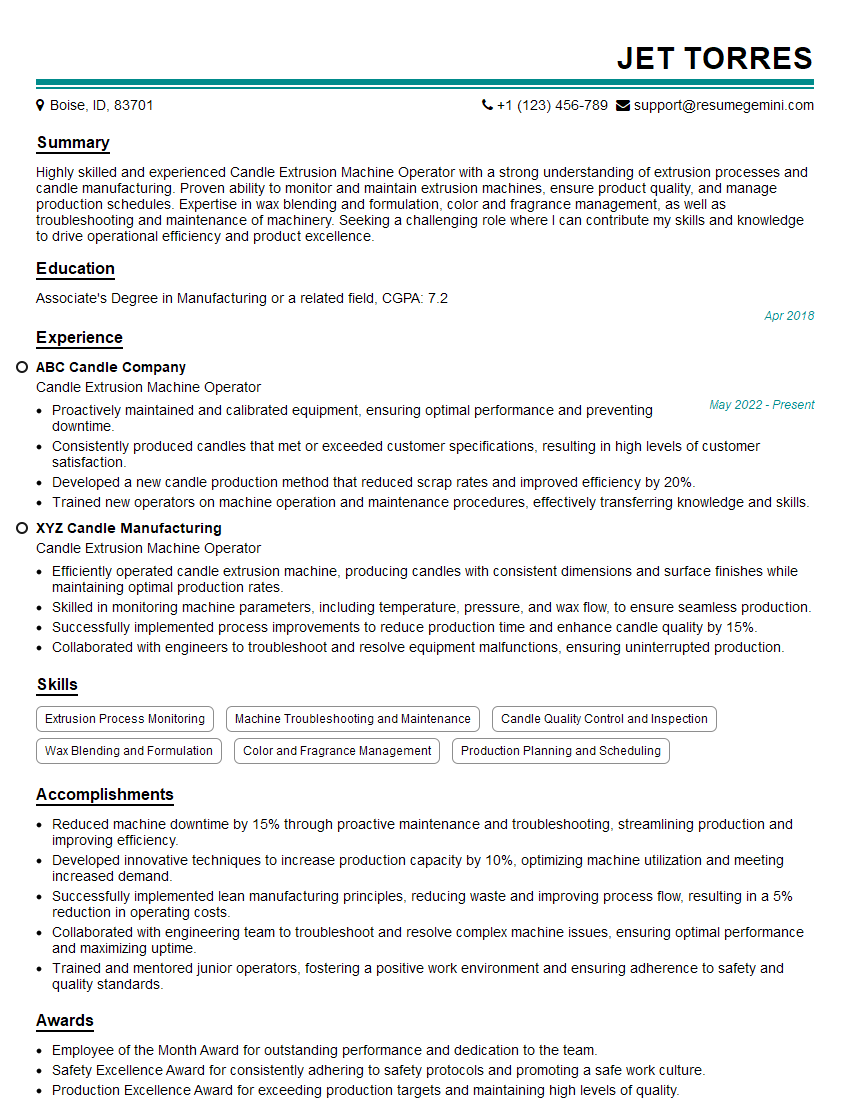

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Candle Extrusion Machine Operator

1. Explain the process of candle extrusion in detail.

- The process of candle extrusion begins with molten wax being fed into an extrusion machine, usually via a hopper or auger.

- Inside the machine, the wax is heated and forced through a shaped die, which determines the shape and size of the candle.

- As the extruded wax emerges from the die, it is cooled and solidified by passing through a cooling tunnel or water bath.

- The cooled candle is then cut to the desired length and packaged for sale.

2. What are the key factors that affect the quality of extruded candles?

Raw materials:

- The quality and type of wax used can significantly impact the appearance, burn time, and scent of the finished candle.

- Other additives, such as colors, fragrances, and stabilizers, can also affect the candle’s properties.

Extrusion process:

- The temperature, pressure, and speed of the extrusion process can influence the candle’s density, shape, and surface finish.

Post-processing:

- Proper cooling and cutting techniques are essential to ensure the candle’s stability and appearance.

3. Describe the different types of candle extrusion machines.

- Single-screw extruders: These machines use a single screw to convey and melt the wax, providing a relatively low production rate.

- Twin-screw extruders: These machines use two intermeshing screws to mix and convey the wax, offering higher production rates and better product consistency.

- Vertical extruders: These machines are designed for producing tall, slender candles, such as tapers or pillars.

- Horizontal extruders: These machines are suitable for producing wider, flatter candles, such as votives or tealights.

4. What are the common troubleshooting issues encountered in candle extrusion?

- Air bubbles in the wax can cause voids or imperfections in the finished candle.

- Temperature variations during the extrusion process can affect the candle’s shape and consistency.

- Improper cooling can lead to cracks or warpage in the candle.

- Blockages in the extrusion die or cooling tunnel can disrupt production.

5. How do you ensure the safety and efficiency of a candle extrusion operation?

- Regularly inspect and maintain the extrusion equipment to prevent breakdowns and ensure optimal performance.

- Use appropriate safety gear, such as gloves, eye protection, and earplugs, to minimize exposure to hazards.

- Follow proper operating procedures and adhere to safety protocols.

- Monitor production parameters, such as temperature, pressure, and speed, to identify and address any deviations.

- Implement quality control measures to ensure consistent production of high-quality candles.

6. What is the importance of quality control in candle extrusion?

- Quality control ensures that the extruded candles meet the desired specifications and customer requirements.

- It helps maintain product consistency, preventing variations in appearance, burn time, and scent.

- Proper quality control minimizes the risk of defects, reducing waste and enhancing customer satisfaction.

- It allows for continuous process improvement, identifying areas for optimization and enhancing overall efficiency.

7. Describe the different methods used to decorate extruded candles.

- Dipping: Candles are dipped into a melted wax or coating to create a colored or textured finish.

- Spraying: Candles are sprayed with paint or other decorative materials to create designs or patterns.

- Embossing: Candles are pressed or stamped with a design to create a raised or recessed pattern.

- Hand-painting: Candles are painted by hand to create intricate designs or artwork.

8. What are the current trends in candle extrusion technology?

- Automation and process optimization to enhance efficiency and reduce labor costs.

- Development of new wax formulations and additives to improve candle performance and aesthetics.

- Incorporation of sustainable and eco-friendly materials to reduce environmental impact.

- Integration of advanced technologies, such as artificial intelligence (AI) and machine learning, to optimize production and quality control.

9. How do you stay updated with the latest advancements in candle extrusion technology?

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Consult with equipment manufacturers and industry experts.

- Participate in online forums and discussion groups.

10. What sets you apart as the ideal candidate for this Candle Extrusion Machine Operator position?

- Extensive experience in operating and maintaining candle extrusion machines.

- Proven ability to troubleshoot and resolve production issues promptly.

- Strong understanding of candle extrusion processes and quality control procedures.

- Excellent communication and interpersonal skills to interact effectively with colleagues and supervisors.

- Commitment to safety, efficiency, and continuous improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Candle Extrusion Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Candle Extrusion Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Candle Extrusion Machine Operator is responsible for the efficient and safe operation of candle extrusion machines. The primary duties include:

1. Machine Operation

Operate and monitor candle extrusion machines to produce candles of various shapes and sizes.

- Set up and adjust machine parameters, such as temperature, speed, and pressure.

- Monitor machine performance and make necessary adjustments to ensure optimal production.

2. Product Quality Control

Inspect and evaluate candles produced by the machine to ensure they meet quality standards.

- Check for defects, such as uneven edges, air bubbles, or discoloration.

- Take corrective action, such as adjusting machine settings or replacing materials, to improve quality.

3. Machine Maintenance

Perform routine maintenance and cleaning of the candle extrusion machine.

- Inspect and lubricate machine components to prevent breakdowns.

- Clean and sanitize equipment to maintain a hygienic work environment.

4. Production Monitoring and Reporting

Monitor and record production data, including machine output and candle quality.

- Identify and address any production issues promptly.

- Prepare reports and documentation on machine performance and production quality.

Interview Tips

To ace an interview for the Candle Extrusion Machine Operator position, candidates should:

1. Research the Company and Role

Read about the company’s values, products, and the specific responsibilities of the role.

- Demonstrate your knowledge of the industry and the company’s reputation.

- Tailor your answers to specific examples that highlight your skills and experience.

2. Highlight Technical Skills

Emphasize your technical abilities, such as machine operation, maintenance, and quality control.

- Provide specific examples of your experience with candle extrusion machines or similar equipment.

- Discuss your understanding of machine settings, troubleshooting techniques, and quality standards.

3. Demonstrate Attention to Detail

Show that you have a keen eye for detail and are committed to producing high-quality products.

- Explain your experience in inspecting and evaluating candles. Explain any quality control procedures you have implemented.

- Discuss your understanding of the importance of cleanliness, hygiene, and safety in the production environment.

4. Emphasize Problem-Solving Abilities

Highlight your ability to identify and resolve production issues efficiently.

- Provide examples of how you have resolved machine breakdowns or production problems in the past.

- Explain your approach to problem-solving and collaboration.

5. Be Prepared with Questions

Prepare thoughtful questions to ask the interviewer. This shows that you are engaged and interested in the role.

- Ask about the company’s plans for growth, the role’s career path, or any specific challenges faced by the team.

- Asking well-informed questions will impress the interviewer and leave a lasting impression.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Candle Extrusion Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Candle Extrusion Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.