Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Candle Molder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Candle Molder so you can tailor your answers to impress potential employers.

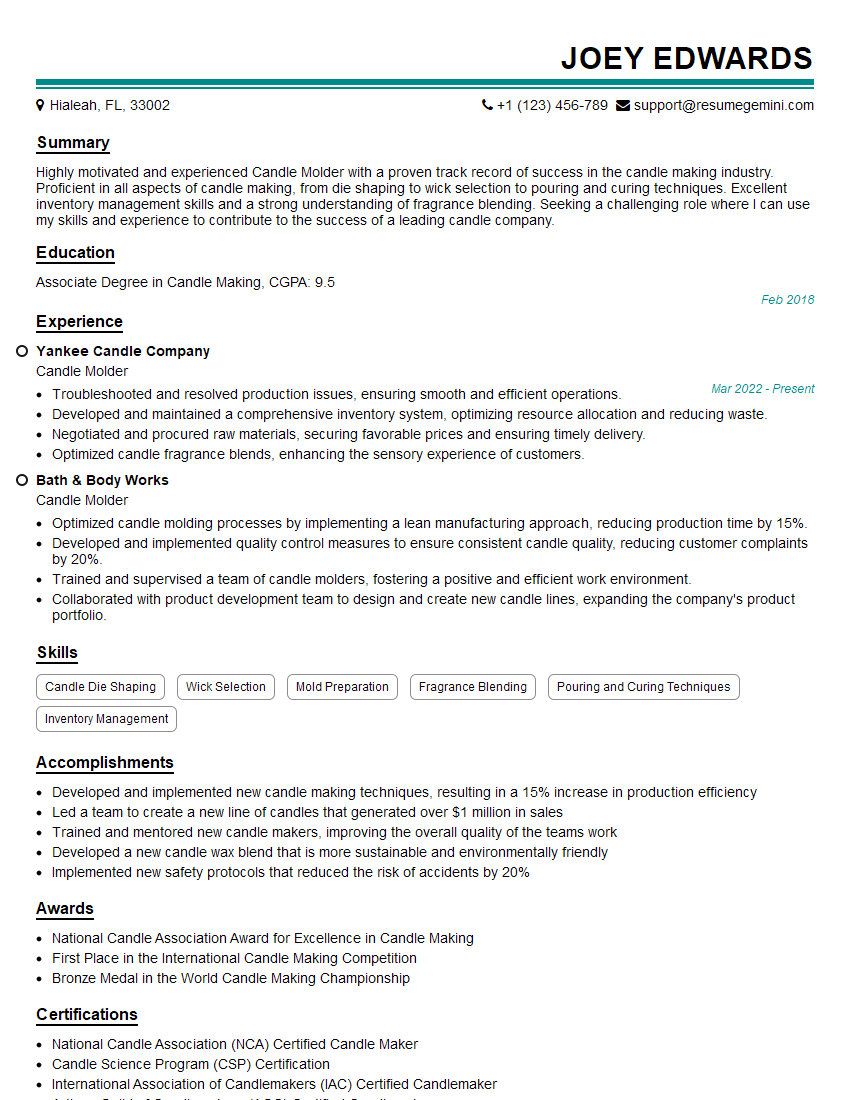

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Candle Molder

1. What types of waxes are commonly used in candle making and what are their advantages and disadvantages?

- Paraffin wax: Derived from petroleum, it’s affordable, easy to work with, and has a high melting point. However, it can be brittle and produce soot when burned.

- Soy wax: Made from soybeans, it’s eco-friendly, burns cleanly, and has a creamy texture. But it has a lower melting point and can be more expensive.

- Beeswax: Natural and renewable, it burns slowly and emits a pleasant scent. However, it’s relatively costly and can be difficult to work with.

- Gel wax: Made from mineral oil, it creates transparent candles with a long burn time. It can be challenging to handle and requires special wicking.

2. Explain the process of preparing candle wicks for use.

Selecting the Right Wicks

- Choose wicks designed for the specific type of wax being used.

- Consider the size and shape of the candle to determine the appropriate wick thickness.

Preparing the Wicks

- Cut the wicks to the desired length, leaving an extra inch for trimming later.

- Dip the wick ends in melted wax and allow them to cool to stabilize the fibers.

- Center the wick in the candle mold and secure it at the bottom with a wick tab or adhesive.

3. Describe the different pouring techniques used in candle making and their impact on the finished product.

- Single pour: Pouring all of the melted wax into the mold at once, resulting in a consistent and uniform candle.

- Double pour: Pouring half of the wax, letting it cool and harden, then pouring the remaining wax, creating a two-layer effect.

- Layer pour: Pouring different colors of wax in layers to create a multi-colored candle.

- Container pour: Pouring melted wax into a pre-made container, such as a jar or tin.

4. How do you ensure that the candles you produce meet safety standards and burn optimally?

- Follow recommended wick sizes and materials: Prevent excessive smoking, soot, or dripping.

- Use high-quality waxes: Ensure proper burn time and minimize impurities.

- Test burn candles before selling: Check for proper wick performance, burn time, and any potential safety issues.

- Comply with safety regulations: Adhere to industry standards and guidelines for candle making.

5. Discuss the factors that can affect the burn time of a candle.

- Wick size: Larger wicks burn faster, resulting in shorter burn times.

- Wax type: Different waxes have varying burn rates, affecting the overall burn time.

- Candle size: Larger candles have more wax, leading to longer burn times.

- Environmental conditions: Drafts or extreme temperatures can influence burn time.

6. Explain the different methods for adding scents to candles and how each method impacts the fragrance throw.

- Essential oils: Natural and concentrated, offer strong scents but can be expensive.

- Fragrance oils: Synthetic, provide a wide variety of scents at a lower cost but may not be as long-lasting.

- Candle wax additives: Pre-mixed with wax, convenient but may limit scent options and throw.

- Candle dyes: Can be scented, but primarily used for color and may have a weaker fragrance throw.

7. Describe the importance of curing candles and explain the ideal conditions and duration for optimal curing.

- Stabilizes the wax: Allows the wax to fully harden and develop a uniform consistency.

- Enhances scent throw: Curing allows fragrances to blend and release more potently.

- Optimum temperature: 70-80°F (21-27°C) promotes slow and even cooling.

- Duration: 2-4 weeks allows sufficient time for the candle to fully cure.

8. What steps do you take to ensure that the candles you produce are consistent in appearance, size, and fragrance?

- Standardized molds: Use consistent sizes and shapes to maintain uniformity.

- Precise weighing: Measure wax, scents, and dyes accurately for consistent wax blends.

- Controlled pouring: Use a consistent pouring technique to achieve even burn surfaces.

- Quality control: Inspect candles regularly to ensure they meet established standards.

9. Explain the different types of candle finishes and how they impact the aesthetics and functionality of the candle.

- Smooth finish: Achieved by using high-quality wax and pouring techniques, creates a clean and polished appearance.

- Textured finish: Created by adding additives or using a textured mold, provides a unique and decorative look.

- Embossed finish: Designs or patterns are pressed into the wax while it’s still soft, creating a raised effect.

- Drizzled finish: Drizzling a contrasting color of wax over the candle’s surface creates a unique and stylish touch.

10. Describe the process of creating custom candles and how you would collaborate with clients to design and produce their desired products.

- Consultation: Discuss client’s preferences, including scents, colors, shapes, and finishes.

- Sample creation: Create prototype candles to demonstrate different options and adjust as needed.

- Production: Once the client is satisfied with the samples, produce the desired quantity of custom candles.

- Packaging and labeling: Design custom packaging and labels that align with the client’s brand or event.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Candle Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Candle Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Candle Molder is responsible for creating candles using specialized molds and techniques. The key responsibilities include:

1. Preparing and Measuring Raw Materials

Candle Molders must ensure the proper mixture and measurement of wax, fragrance oils, colorants, and wicks.

- Calculate and weigh the ingredients according to established formulas.

- Melt wax and add fragrance oils and colorants while controlling temperature.

2. Molding and Curing Candles

They skillfully pour molten wax into molds and handle the curing process to ensure the quality of the finished candles.

- Select and prepare appropriate molds.

- Pour wax into molds and insert wicks correctly.

- Monitor the cooling and curing process to ensure optimal crystallization.

3. Maintaining Production Equipment

Candle Molders maintain and clean specialized equipment to ensure smooth production.

- Inspect and clean melting pots, molds, and other tools.

- Perform basic maintenance on equipment as needed.

4. Quality Control and Safety Compliance

They play a crucial role in ensuring the quality of candles and adhering to safety standards.

- Inspect finished candles for defects and ensure they meet specifications.

- Follow all safety protocols related to handling wax, fragrances, and equipment.

Interview Tips

To ace the interview for a Candle Molder position, it’s important to prepare thoroughly. Here are some tips:

1. Research the Company and Role

Familiarize yourself with the company’s background, values, and the specific responsibilities of the Candle Molder role.

- Visit the company website and social media pages.

- Review job descriptions and industry publications.

2. Highlight Your Experience and Skills

Emphasize your prior experience in candle making or a related field. Showcase your skills in handling wax, molding, and maintaining equipment.

- Quantify your accomplishments and provide specific examples.

- Explain how your skills align with the job requirements.

3. Understand the Production Process

Demonstrate your understanding of the candle-making process, including the steps involved, materials used, and potential challenges.

- Explain the different types of waxes and their properties.

- Describe the role of fragrance oils and colorants in candle making.

4. Emphasize Safety and Quality

Highlight your commitment to safety and quality control in the workplace.

- Share your knowledge of industry safety standards.

- Explain your approach to ensuring product quality and customer satisfaction.

5. Practice Your Answers

Prepare answers to common interview questions and practice delivering them concisely and effectively.

- Consider questions about your experience, skills, and motivations.

- Seek feedback from a friend or family member on your answers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Candle Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!