Feeling lost in a sea of interview questions? Landed that dream interview for Candles Pourer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Candles Pourer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

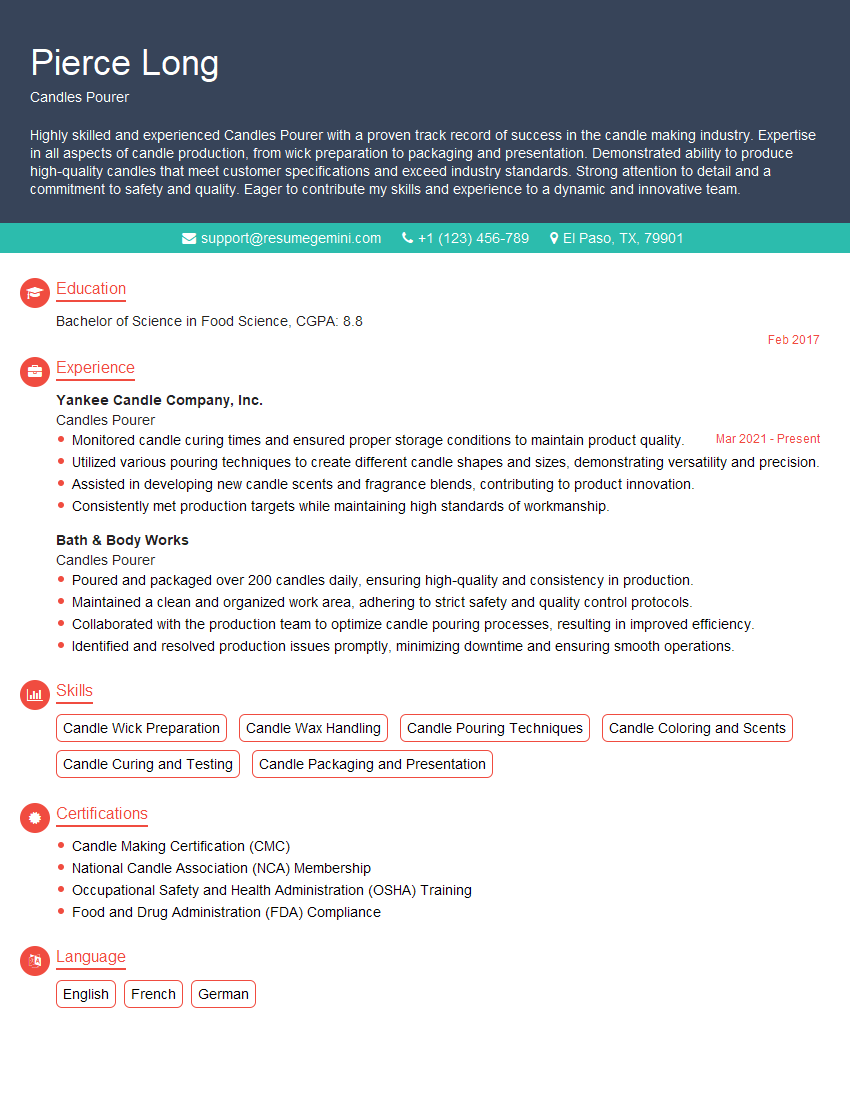

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Candles Pourer

1. What are the different types of waxes used in candle making and their properties?

There are various types of waxes used in candle making, each with its unique properties. Here are a few common types:

- Soy Wax: Made from soybeans, soy wax is eco-friendly, burns cleanly, and has good fragrance retention.

- Paraffin Wax: A petroleum-based wax, paraffin is widely used for its low cost and strong hold for wicks.

- Beeswax: Natural and renewable, beeswax produces a warm glow, has a long burn time, and emits a subtle honey scent.

- Gel Wax: A petroleum-based gel, gel wax is transparent, allowing for creative candle designs with embedded objects.

- Palm Wax: Derived from palm oil, palm wax has a creamy texture, good fragrance throw, and is often blended with other waxes.

2. How do you measure and adjust the fragrance oil concentration in candles?

Measuring Fragrance Oil Concentration:

- Use a digital scale to accurately measure both the wax and fragrance oil by weight.

- Calculate the percentage of fragrance oil based on the total weight of the wax.

Adjusting Fragrance Oil Concentration:

- Start with a fragrance load of 5-10% for most waxes.

- Adjust the amount of fragrance oil slightly based on the desired scent strength.

- Test burn candles to determine the optimal fragrance throw and make necessary adjustments.

3. What is the importance of wick selection and how do you determine the appropriate wick size for a candle?

Selecting the right wick size is crucial for candle performance and safety. Here’s how to determine the appropriate wick size:

- Diameter of the Candle: Generally, wider candles require larger wicks.

- Type of Wax: Different waxes have varying burn rates, which should be considered when choosing a wick size.

- Fragrance Load: Higher fragrance concentrations can affect the burn rate, requiring a slightly larger wick.

- Burn Test: Conduct burn tests to observe the flame stability and wax consumption rate.

- Wick Material: Natural fiber wicks burn slower than cotton, so they may require a smaller size.

4. How do you cure candles properly and what are the benefits of curing?

Curing allows candles to fully scent and stabilize before burning. Proper curing involves the following steps:

- Store candles in a cool, dark place with good air circulation.

- Let candles cure for at least 2 weeks, depending on the size and wax type.

- During curing, the fragrance oil blends with the wax, resulting in a stronger and more balanced scent throw.

- Curing also strengthens the bond between the wick and wax, improving burn performance.

5. What are the safety precautions to consider when pouring candles?

Safety is paramount when pouring candles. Here are some essential precautions:

- Wear appropriate protective gear, including gloves, safety glasses, and a mask.

- Work in a well-ventilated area to avoid inhaling fumes from melted wax and fragrance oils.

- Keep flammable materials away from the pouring area.

- Use a double boiler to melt wax, preventing overheating and potential fire hazards.

- Allow the melted wax to cool slightly before adding fragrance oil to prevent evaporation and loss of scent.

6. How do you troubleshoot common candle-making problems, such as tunneling or frosting?

Tunneling:

- Use a larger wick size to create a hotter flame.

- Center the wick properly to ensure even wax consumption.

- Avoid burning candles for extended periods without trimming the wick.

Frosting:

- Ensure the wax is melted to the correct temperature before pouring.

- Cool candles slowly and gradually to minimize temperature fluctuations.

- Use a fan to circulate air around the candles while they are cooling.

7. What are some innovative candle-making techniques or trends?

Candle-making is constantly evolving with new techniques and trends emerging. Here are a few examples:

- Container Candles: Poured into unique and decorative containers, such as ceramic, glass, or metal.

- Melt Pools: Candles designed to create a large, melted wax pool for ambient lighting.

- Embellished Candles: Candles adorned with crystals, glitter, or dried flowers for a decorative touch.

- Scented Candles: Candles infused with essential oils or fragrance blends to create specific scents.

- Custom Candles: Candles tailored to personal preferences, including fragrance, color, and shape.

8. How do you ensure that candles meet safety regulations and industry standards?

Adhering to safety regulations and industry standards is crucial for candle makers. Here are some key measures:

- Use high-quality, non-toxic materials in candle making.

- Comply with CPSC (Consumer Product Safety Commission) regulations, including wick length and warning labels.

- Conduct burn tests to ensure candles burn safely and consistently.

- Obtain necessary certifications, such as CLP (Classification, Labelling, and Packaging) for candles sold in the EU.

- Stay up-to-date with industry best practices and advancements.

9. How do you calculate the cost of producing candles and set appropriate pricing?

Calculating Production Cost:

- Determine the cost of raw materials, including wax, wicks, fragrance oils, and containers.

- Factor in labor costs for pouring, curing, and packaging.

- Consider overhead expenses, such as rent, utilities, and equipment maintenance.

Setting Pricing:

- Research market prices for similar candles.

- Consider the value and uniqueness of your candles.

- Set a price that covers production costs, provides reasonable profit margins, and is competitive in the market.

10. How do you stay updated with the latest trends and advancements in candle making?

Staying updated is essential in the candle-making industry. Here are some strategies:

- Attend industry trade shows and workshops.

- Read candle-making blogs, magazines, and online forums.

- Experiment with new materials, techniques, and fragrance combinations.

- Join professional organizations and connect with other candle makers.

- Research and explore emerging trends to stay ahead of the market.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Candles Pourer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Candles Pourer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Candles Pourer is responsible for preparing and pouring candle wax into molds to create various types of scented or unscented candles. They ensure the proper measurements and proportions of ingredients, maintaining high-quality standards throughout the process.

1. Candle Production

Preparing candle wax by melting and mixing ingredients according to specified formulas and ratios.

- Pouring the molten wax into molds of various shapes and sizes.

- Monitoring the cooling and solidification process to ensure the candles meet quality standards.

- Trimming and finishing the candles to remove any imperfections or excess wax.

2. Quality Control

Inspecting the finished candles for defects such as cracks, bubbles, or uneven surfaces.

- Checking the weight and dimensions of candles to ensure they meet specifications.

- Testing the burn time and scent throw of candles to ensure they perform as expected.

- Maintaining records of production and quality control procedures.

3. Equipment Maintenance

Cleaning and maintaining candle-making equipment, including wax melters, molds, and pouring tools.

- Monitoring equipment performance and reporting any issues or malfunctions.

- Following established safety protocols for handling hot wax and flammable materials.

4. Customer Service

Interacting with customers to answer questions about candle products and provide assistance.

- Providing information about candle scents, burn times, and safety precautions.

- Handling customer inquiries and resolving complaints promptly and effectively.

Interview Tips

To ace the interview for a Candles Pourer position, it is crucial to highlight your skills, experience, and enthusiasm for the role. Here are some interview preparation tips to help you stand out:

1. Research the Company and Role

Thoroughly research the company’s website, social media pages, and industry news to gain insights into their culture, values, and candle-making process. This knowledge will demonstrate your interest in the position and the company.

- Familiarize yourself with the specific responsibilities of the Candles Pourer role and identify how your skills and experience align with them.

- Prepare questions to ask the interviewer about the company’s candle-making techniques, quality standards, and growth opportunities.

2. Highlight Your Skills and Experience

Emphasize your technical skills in candle-making, including wax handling, mold pouring, and quality control. Quantify your experience whenever possible using specific examples.

- Discuss your understanding of different candle waxes, wicks, and scents, and how you use this knowledge to create high-quality candles.

- Highlight your attention to detail and precision in your work, ensuring that candles meet exact specifications and customer expectations.

3. Demonstrate Your Passion for Candles

Share your enthusiasm for the art and science of candle-making, expressing your passion for creating beautiful and fragrant products that enhance people’s lives.

- Explain how you stay up-to-date with industry trends and innovations in candle-making.

- Discuss your personal experiences with using candles and how they have influenced your interest in the field.

4. Prepare for Common Interview Questions

Prepare thoughtful answers to common interview questions, such as:

- “Tell me about your experience in candle-making and what makes you qualified for this role?”

- “Describe your understanding of the different types of candle waxes and their properties.”

- “How do you ensure that candles meet quality standards and customer expectations?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Candles Pourer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.