Are you gearing up for an interview for a Candy Polisher position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Candy Polisher and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

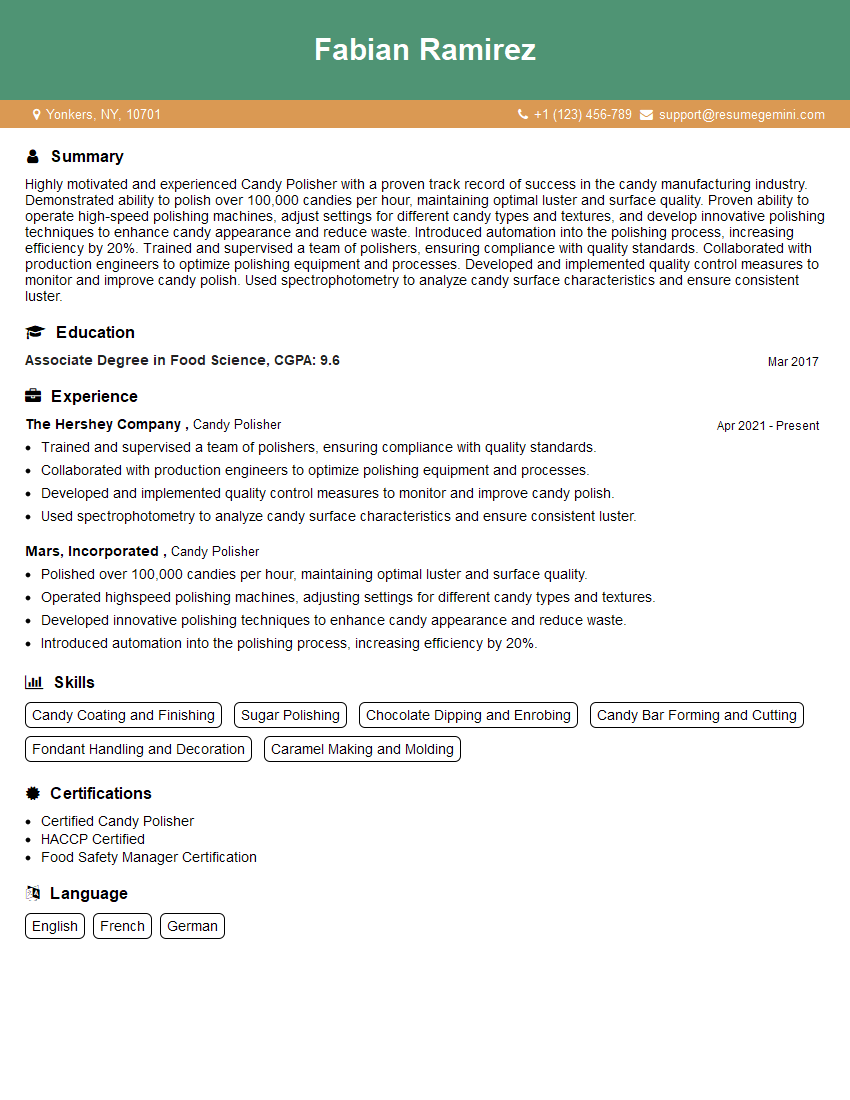

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Candy Polisher

1. What are the different types of candy polishing machines used in the industry?

There are three main types of candy polishing machines used in the industry:

- Horizontal Panning Machines: These machines rotate horizontally and use friction to polish the candy.

- Vertical Panning Machines: These machines rotate vertically and use a combination of friction and tumbling to polish the candy.

- Centrifugal Polishers: These machines use centrifugal force to polish the candy.

2. What are the key factors that affect the quality of candy polishing?

Machine Factors

- Machine type and speed

- Pan size and shape

- Polishing media used

Candy Factors

- Candy composition

- Candy temperature

- Candy moisture content

Process Factors

- Polishing time

- Polishing temperature

- Humidity

3. Describe the steps involved in the candy polishing process.

- Preparing the Candy: The candy is heated to a specific temperature and then cooled to a workable temperature.

- Loading the Panning Machine: The candy is loaded into the panning machine along with the polishing media.

- Polishing: The panning machine is rotated to polish the candy. The speed and duration of polishing depend on the type of candy and the desired finish.

- Unloading the Candy: The polished candy is unloaded from the panning machine.

4. What are the common defects that can occur during candy polishing?

- Overpolishing: The candy is polished too long, resulting in a dull finish.

- Underpolishing: The candy is not polished long enough, resulting in a rough finish.

- Streaking: The candy is polished unevenly, resulting in streaks on the surface.

- Sticking: The candy sticks to the panning machine or the polishing media.

5. How do you troubleshoot common defects in candy polishing?

- Overpolishing: Reduce the polishing time or speed.

- Underpolishing: Increase the polishing time or speed.

- Streaking: Ensure the candy is evenly distributed in the panning machine and that the polishing media is well mixed.

- Sticking: Adjust the candy temperature or moisture content, or use a different type of polishing media.

6. What are the safety precautions that should be followed when operating a candy polishing machine?

- Never operate a candy polishing machine without proper training.

- Always wear appropriate safety gear, including gloves, safety glasses, and a hairnet.

- Keep the machine clean and free of debris.

- Never reach into a running machine.

- Follow all manufacturer’s instructions for safe operation.

7. What are the maintenance procedures that should be performed on a candy polishing machine?

- Daily: Clean the machine and inspect for any loose or damaged parts.

- Weekly: Lubricate the machine according to manufacturer’s instructions.

- Monthly: Check the belts and bearings for wear and tear.

- Annually: Have the machine inspected by a qualified technician.

8. What are the different types of polishing media used in candy polishing?

- Natural: Includes materials like beeswax, carnauba wax, and gum arabic.

- Synthetic: Includes materials like polyethylene glycol and polyvinyl alcohol.

- Hybrid: Combinations of natural and synthetic materials.

9. How do you select the right polishing media for a specific candy application?

- Consider the type of candy being polished.

- Consider the desired finish.

- Consider the machine being used.

- Consult with a supplier or manufacturer to determine the best polishing media for your application.

10. What are the latest trends in candy polishing technology?

- Automation: Automated candy polishing machines can reduce labor costs and improve efficiency.

- Inline Polishing: Inline polishing systems can eliminate the need for manual handling between polishing and packaging.

- Eco-Friendly Polishing: New polishing media and processes are being developed to reduce environmental impact.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Candy Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Candy Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Candy Polishers are responsible for the final finishing of candy products. They use a variety of tools and techniques to polish and shine candy, ensuring that it meets the company’s quality standards.

1. Candy Polishing

The primary responsibility of a Candy Polisher is to polish and shine candy products.

- Operate polishing machines to remove excess sugar and create a smooth, shiny surface.

- Use a variety of polishing tools and techniques to achieve the desired finish.

2. Candy Inspection

Candy Polishers are also responsible for inspecting candy products for defects.

- Inspect candy for imperfections, such as chips, cracks, or discoloration.

- Remove defective candy from the production line and report any quality control issues.

3. Machine Maintenance

Candy Polishers are also responsible for maintaining their equipment.

- Clean and maintain polishing machines and other equipment.

- Report any equipment problems to their supervisor.

4. Work Environment

Candy Polishers typically work in a fast-paced environment.

- Work in a production environment that may be noisy and dusty.

- Stand for long periods of time and perform repetitive tasks.

Interview Tips

Preparing well for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Candy Polisher position:

1. Research the Company and Position

Before the interview, take some time to learn about the company and the specific Candy Polisher position you are applying for.

- Visit the company’s website to learn about their products, services, and culture.

- Review the job description carefully and make note of the key responsibilities and qualifications required.

2. Practice Your Answers

Take some time to practice answering common interview questions.

- Consider questions about your experience, skills, and why you are interested in the position.

- Prepare specific examples to support your answers and highlight your relevant skills.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview.

- Wear clean, pressed clothes that are appropriate for a business setting.

- Avoid wearing casual clothing, such as jeans or t-shirts.

4. Be Enthusiastic and Positive

Employers want to hire people who are enthusiastic and positive about their work.

- During the interview, be friendly and approachable.

- Show interest in the position and the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Candy Polisher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Candy Polisher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.