Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cane Burner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

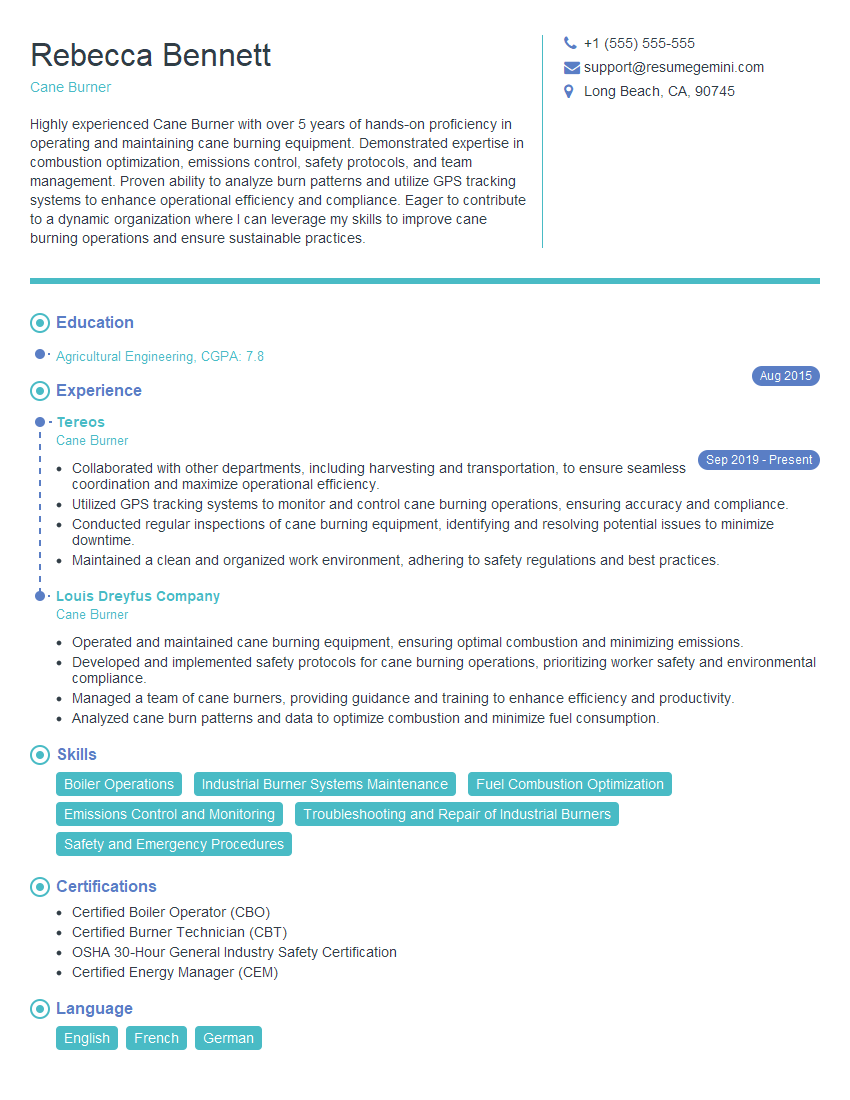

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cane Burner

1. What types of cane are suitable for sugar production and what factors influence their suitability?

- Suitable cane varieties include Saccharum officinarum, Saccharum robustum, and Saccharum barberi due to their high sucrose content and easy cultivation.

- Climatic factors such as temperature, rainfall, and sunshine duration affect cane growth and sugar content.

- Soil conditions, including pH, nutrient availability, and drainage, also play a role in cane suitability.

2. Describe the process of cane preparation and its importance in sugar production.

- Cane is harvested manually or mechanically, ensuring minimal damage to stalks to prevent sucrose loss.

- Cane is cleaned to remove trash, soil, and leaves, and depithed to extract the juice-rich rind.

- Depithed cane is crushed and milled to extract the juice, which contains sucrose, water, and impurities.

Cutting and harvesting

Cleaning and depithing

Crushing and milling

3. Explain the role of a cane burner in sugar production.

- Cane burners burn the bagasse, a byproduct of cane milling, to generate steam and heat.

- The steam is used to drive turbines for power generation and to heat the juice in the evaporation process.

- The heat from the burner also helps to dry the bagasse, making it suitable for use as a fuel or soil amendment.

4. What are the key factors to consider when operating a cane burner?

- Fuel quality and moisture content to ensure efficient combustion.

- Burner design and maintenance to optimize heat transfer and minimize emissions.

- Control of combustion parameters such as temperature, pressure, and air-to-fuel ratio to ensure stable operation.

- Environmental regulations and safety protocols to minimize pollution and protect personnel.

5. How do you troubleshoot common problems encountered in cane burner operation?

- Low steam output: Check fuel quality, combustion parameters, and burner maintenance.

- High emissions: Adjust air-to-fuel ratio, optimize burner design, and ensure proper combustion.

- Fuel bridging: Ensure proper fuel feed, monitor fuel moisture, and adjust burner design.

- Clinker formation: Control combustion temperature, optimize fuel quality, and ensure regular burner cleaning.

6. What are the safety precautions that you strictly adhere to when operating a cane burner?

- Wear appropriate personal protective equipment (PPE) including fire-resistant clothing, gloves, and safety glasses.

- Follow established operating procedures and never override safety devices.

- Regularly inspect and maintain the burner to prevent hazards.

- Be aware of potential hazards such as fire, explosions, and hot surfaces.

- Have an emergency response plan in place and know how to use fire extinguishers and other safety equipment.

7. What is the importance of maintaining optimal temperature in a cane burner?

Maintaining optimal temperature in a cane burner is critical for several reasons:

- Efficient combustion: Optimal temperature ensures complete combustion of fuel, maximizing heat transfer and steam generation.

- Minimized emissions: Proper temperature control reduces the formation of harmful pollutants such as nitrogen oxides and carbon monoxide.

- Protection of equipment: Excessive temperatures can damage burner components, leading to costly repairs and downtime.

- Fuel conservation: Optimal temperature optimizes fuel utilization, reducing operating costs.

- Improved product quality: In sugar production, maintaining the correct temperature during juice heating helps preserve sucrose content and prevent caramelization.

8. How do you monitor and control the air-to-fuel ratio in a cane burner?

Monitoring and controlling the air-to-fuel ratio (AFR) in a cane burner is essential for efficient and safe operation:

- Oxygen sensors: Oxygen sensors measure the amount of oxygen present in the combustion chamber, providing real-time feedback on the AFR.

- Fuel flow meters: Fuel flow meters track the amount of fuel being supplied to the burner, allowing for precise adjustment of the AFR.

- Automatic control systems: Advanced control systems use sensors and algorithms to continuously monitor and adjust the AFR, maintaining optimal combustion conditions.

- Manual adjustments: In some cases, manual adjustments to the fuel supply or air dampers may be necessary to achieve the desired AFR.

- Regular monitoring: Regular monitoring of the AFR using portable analyzers or built-in instrumentation helps ensure consistent and efficient combustion.

9. Describe the role of a PLC (Programmable Logic Controller) in a cane burner control system.

A PLC (Programmable Logic Controller) plays a vital role in the control system of a cane burner:

- Programmable logic: PLCs are equipped with programmable logic that allows for customization of control sequences and algorithms.

- Real-time monitoring: PLCs continuously monitor inputs from sensors, such as temperature, pressure, and flow, providing real-time data on burner operation.

- Decision-making: Based on the programmed logic and sensor inputs, the PLC makes decisions to adjust burner parameters, such as fuel flow and air supply.

- Output control: The PLC sends control signals to actuators and other devices to implement the decisions made, ensuring optimal burner performance.

- Communication: PLCs can communicate with other control systems and devices, enabling remote monitoring and data logging.

10. How do you prioritize preventive maintenance tasks for a cane burner to minimize downtime?

Prioritizing preventive maintenance tasks for a cane burner is crucial to minimize downtime and ensure reliable operation:

- Risk assessment: Identify critical components and potential failure points based on historical data and industry best practices.

- Scheduling: Establish a regular maintenance schedule based on the risk assessment, considering factors such as operating hours and environmental conditions.

- Condition monitoring: Implement condition monitoring techniques, such as vibration analysis and thermal imaging, to detect potential issues early.

- Parts inventory: Maintain an adequate inventory of essential spare parts to minimize delays in case of breakdowns.

- Training: Ensure that maintenance personnel are properly trained and have the necessary skills to perform preventive maintenance effectively.

- Documentation: Keep detailed records of all maintenance activities, including inspections, repairs, and replacements, for future reference and analysis.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cane Burner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cane Burner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cane Burner is entrusted with the critical role of operating and maintaining a sugar mill’s cane burner, ensuring the efficient combustion of sugarcane to produce steam and electricity. Key responsibilities include:

1. Combustion Management

Regulating the combustion process to achieve optimal fuel efficiency, steam generation, and minimize emissions.

- Adjusting air flow and fuel feed to maintain desired combustion conditions.

- Monitoring and controlling furnace temperature, pressure, and oxygen levels.

2. Equipment Maintenance

Ensuring the efficient operation and longevity of the cane burner and its associated equipment.

- Performing scheduled maintenance checks and repairs on burners, conveyors, and other components.

- Identifying and addressing potential equipment failures to prevent breakdowns.

3. Process Monitoring

Continuously monitoring the cane burning process and making adjustments as necessary to maintain product quality.

- Analyzing combustion data and making informed decisions to optimize fuel utilization.

- Ensuring compliance with environmental regulations and safety standards.

4. Emergency Response

Responding promptly and effectively to emergencies such as fires, equipment malfunctions, and process upsets.

- Implementing established safety protocols and taking appropriate actions to minimize risks.

- Assisting in the resolution of process issues and troubleshooting equipment problems.

Interview Tips

Interview preparation is crucial for a successful Cane Burner interview. Consider the following tips to enhance your performance:

1. Research the company and industry

Thoroughly research the sugar mill’s operations, production methods, and market position. Understand the industry’s trends, challenges, and best practices.

2. Highlight your technical expertise

Emphasize your knowledge of combustion principles, burner operation, and process control. Quantify your accomplishments and provide specific examples of your contributions.

3. Demonstrate problem-solving skills

Prepare anecdotes that showcase your ability to identify and resolve technical issues in a sugar mill setting. Explain your approach to troubleshooting and implementing solutions.

4. Emphasize safety and compliance

Highlight your commitment to safety and your understanding of environmental regulations. Explain how you ensure compliance and maintain a safe work environment.

5. Prepare for technical questions

Anticipate technical questions related to burner design, combustion optimization, and emission control. Practice answering these questions confidently and accurately.

6. Show your passion

Convey your enthusiasm for the sugar industry and your desire to contribute to the mill’s success. Explain how your skills and experience align with the role and the company’s goals.

Next Step:

Now that you’re armed with the knowledge of Cane Burner interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Cane Burner positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini