Are you gearing up for a career in Cane Flume Feeding Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cane Flume Feeding Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

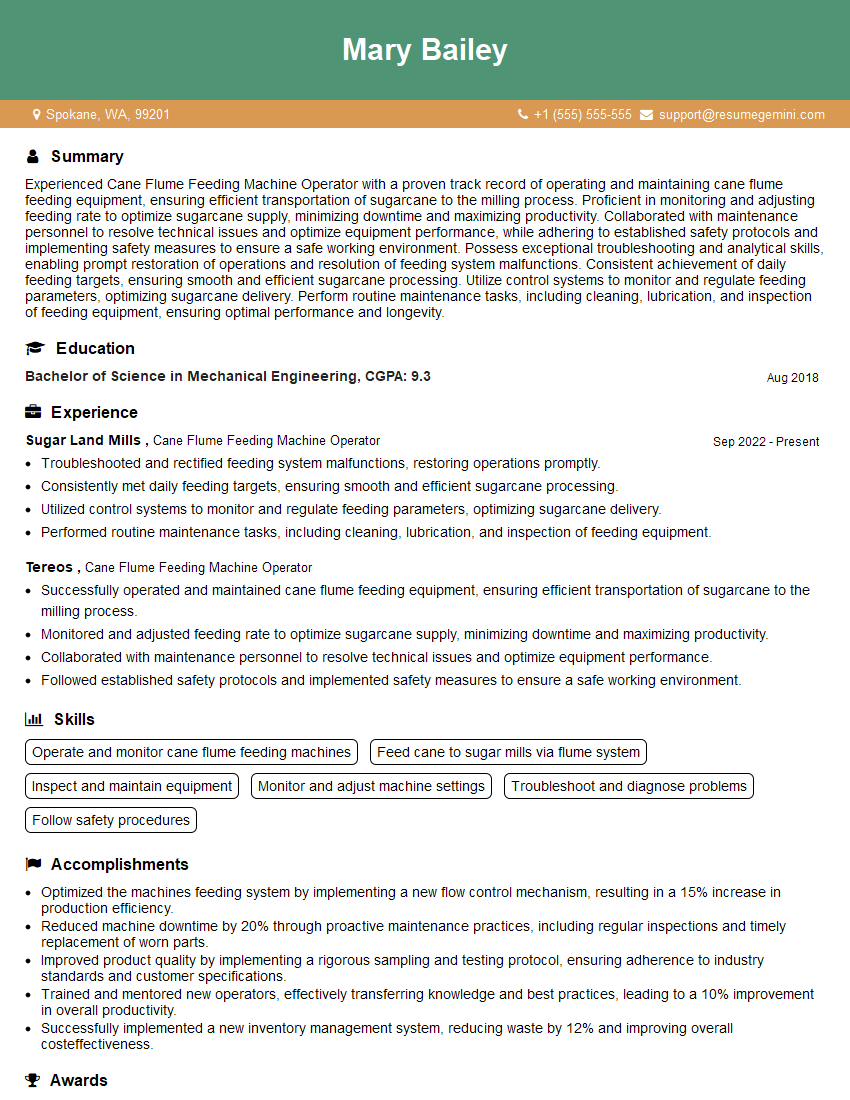

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cane Flume Feeding Machine Operator

1. What are the key responsibilities of a Cane Flume Feeding Machine Operator?

The primary responsibilities of a Cane Flume Feeding Machine Operator include:

- Operating the Cane Flume Feeding Machine to ensure a consistent supply of cane to the mill.

- Monitoring the machine’s performance and making necessary adjustments to maintain optimal operation.

- Troubleshooting and resolving any mechanical issues that may arise.

2. What are the different types of Cane Flume Feeding Machines?

The two main types of Cane Flume Feeding Machines are:

- Fixed-rate machines: These machines feed cane at a constant rate, regardless of the cane’s moisture content or size.

- Variable-rate machines: These machines adjust the feeding rate based on the cane’s moisture content and size, ensuring a more efficient operation.

3. How do you troubleshoot a Cane Flume Feeding Machine that is not functioning properly?

Troubleshooting steps for a malfunctioning Cane Flume Feeding Machine include:

- First, check the power supply and ensure that the machine is receiving power.

- Inspect the machine for any loose connections or damaged components.

- Check the sensors to ensure that they are functioning properly and providing accurate data to the machine’s control system.

- If the problem persists, consult the machine’s maintenance manual or contact the manufacturer for assistance.

4. What is the procedure to perform scheduled maintenance on a Cane Flume Feeding Machine?

Scheduled maintenance on a Cane Flume Feeding Machine typically includes:

- Daily: Checking the machine for any loose connections, damaged components, or unusual noises.

- Weekly: Cleaning the machine and its components, lubricating moving parts, and checking the sensors.

- Monthly: Inspecting the machine’s electrical components, belts, and bearings.

- Annually: Overhauling the machine, replacing worn-out parts, and conducting a thorough inspection.

5. What safety measures should be followed when operating a Cane Flume Feeding Machine?

Important safety measures to follow when operating a Cane Flume Feeding Machine include:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Never reach into the machine while it is in operation.

- Keep the work area clean and free of debris to prevent slips and falls.

- Follow all lockout/tagout procedures before performing any maintenance or repairs.

6. How do you calculate the capacity of a Cane Flume Feeding Machine?

The capacity of a Cane Flume Feeding Machine can be calculated using the following formula:

Capacity (tons per hour) = (Flume width x Velocity) / Density

- Flume width (meters)

- Velocity (meters per second)

- Density (tons per cubic meter)

7. What are the different factors that affect the performance of a Cane Flume Feeding Machine?

Factors that affect the performance of a Cane Flume Feeding Machine include:

- The type of cane being fed

- The moisture content of the cane

- The size of the cane

- The speed of the flume

- The angle of the flume

8. What is the difference between a flume and a conveyor belt?

A flume is a channel through which water flows, while a conveyor belt is a moving belt that transports materials.

- Flumes are typically used for transporting large quantities of material, while conveyor belts are used for transporting smaller quantities.

- Flumes are more efficient than conveyor belts, as they use the force of gravity to transport material.

- Conveyor belts are more versatile than flumes, as they can be used to transport materials in different directions and at different angles.

9. What is the role of a PLC (Programmable Logic Controller) in a Cane Flume Feeding Machine?

A PLC is a computer that controls the operation of a Cane Flume Feeding Machine.

- The PLC receives signals from sensors and switches, and uses these signals to control the speed of the flume, the angle of the flume, and the flow of water.

- The PLC also monitors the performance of the machine and alerts the operator to any problems.

10. What are the advantages of using a variable-rate Cane Flume Feeding Machine over a fixed-rate machine?

Advantages of using a variable-rate Cane Flume Feeding Machine include:

- Improved efficiency: Variable-rate machines can adjust the feeding rate based on the cane’s moisture content and size, ensuring that the mill is always receiving an optimal supply of cane.

- Reduced energy consumption: Variable-rate machines can reduce energy consumption by slowing down the feeding rate when the cane is wet or small.

- Increased mill capacity: Variable-rate machines can help to increase mill capacity by ensuring that the mill is always receiving a consistent supply of cane.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cane Flume Feeding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cane Flume Feeding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cane Flume Feeding Machine Operators play a crucial role in sugarcane processing plants. Their primary responsibility is to ensure the smooth and efficient operation of the cane flume feeding machine, which transports sugarcane from the storage area to the crushing section. The job requires a combination of technical expertise and attention to detail to maintain the machine’s performance and maximize sugarcane processing efficiency.

1. Equipment Operation and Maintenance

Operators are responsible for the proper and safe operation of the cane flume feeding machine. This includes:

- Starting and stopping the machine as needed.

- Monitoring machine parameters such as speed, flow rate, and temperature.

- Performing routine maintenance tasks like lubrication, cleaning, and minor repairs.

2. Material Handling

Operators control the flow of sugarcane into the crushing section by:

- Adjusting the speed of the conveying system.

- Ensuring proper feeding of sugarcane into the machine.

- Removing any obstacles or blockages from the flume.

3. Quality Control

Operators play a vital role in maintaining the quality of sugarcane entering the crushing process. They:

- Inspect sugarcane for foreign objects or contaminants.

- Identify and remove sugarcane that does not meet quality standards.

- Report any quality issues to supervisors.

4. Safety and Compliance

Operators prioritize safety in the workplace by:

- Following all safety protocols and procedures.

- Wearing appropriate protective gear.

- Maintaining a clean and organized work area.

Interview Tips

Preparing for a Cane Flume Feeding Machine Operator interview requires a combination of research, practice, and self-reflection. Here are some essential tips to help you ace the interview:

1. Research the Company and Role

Demonstrate your interest in the company and the position by thoroughly researching their website and industry news. Understand the company’s mission, values, and goals. Tailor your answers to the specific responsibilities outlined in the job description.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses. Practice with a friend, family member, or career counselor to gain feedback and improve your delivery. Some typical questions to prepare for include:

- “Tell me about your experience operating cane flume feeding machines.”

- “How do you handle unexpected equipment malfunctions?”

- “What are your strategies for ensuring the quality of sugarcane entering the crushing process?”

3. Highlight Your Skills and Experience

Quantify your accomplishments and provide specific examples that demonstrate your proficiency in the required skills. Use the STAR method (Situation, Task, Action, Result) to structure your answers and emphasize your contributions.

4. Be Enthusiastic and Professional

Project a positive and enthusiastic attitude throughout the interview. Dress professionally, arrive on time, and maintain eye contact with the interviewer. Ask thoughtful questions to show your engagement and interest in the position.

5. Follow Up After the Interview

Within 24 hours of the interview, send a thank-you note to the interviewer. Express your appreciation for their time and reiterate your interest in the position. Inquire about the next steps in the hiring process.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Cane Flume Feeding Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Cane Flume Feeding Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.