Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cane Packer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cane Packer so you can tailor your answers to impress potential employers.

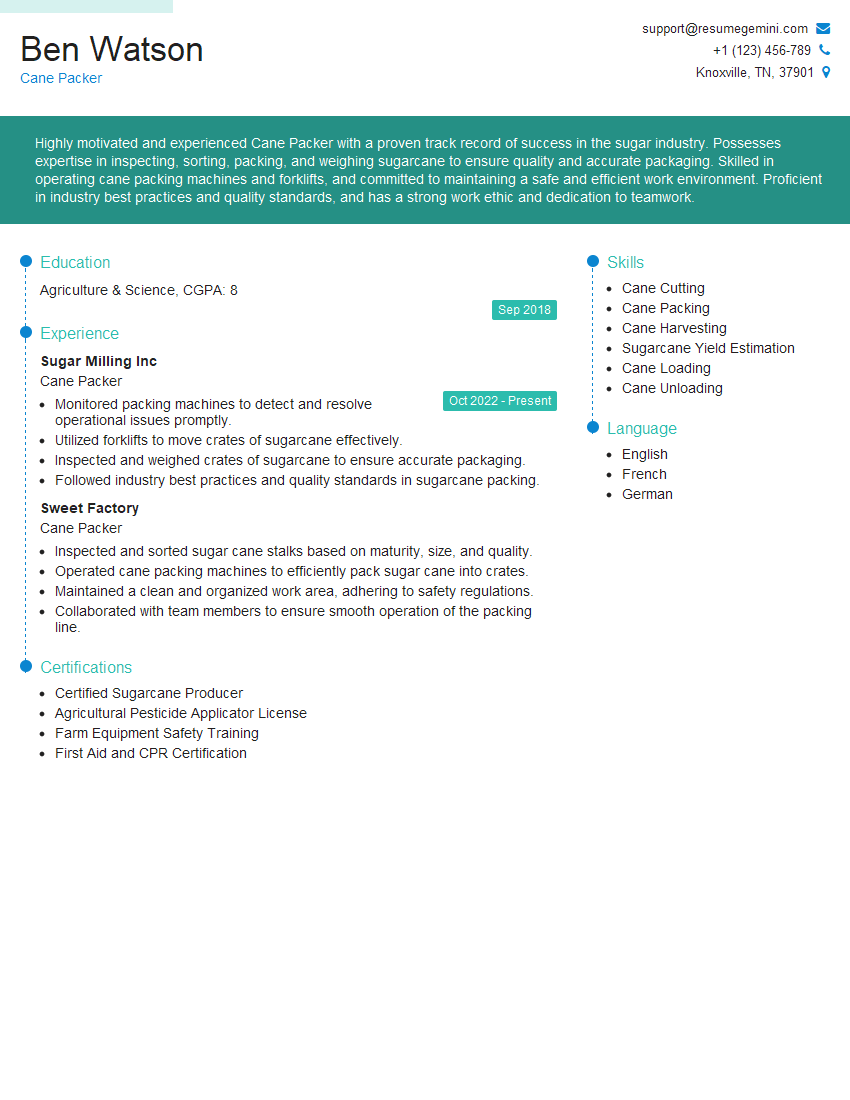

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cane Packer

1. Describe the process of packing sugar cane stalks?

The process of packing sugar cane stalks involves several steps to ensure efficient transportation and preservation:

- Harvesting: Sugar cane stalks are manually cut or mechanically harvested from the field.

- Cleaning and Trimming: Harvested stalks are cleaned to remove any debris, leaves, or excess soil. They are then trimmed to remove any damaged or diseased portions.

- Bundling: Cleaned and trimmed stalks are bundled together using twine or straps to create manageable units for packing.

- Stacking: Bundles of stalks are stacked in a specific pattern within the packing container, ensuring stability and maximizing space utilization.

- Securing: Packed stalks are secured within the container using additional twine, straps, or netting to prevent shifting during transportation.

2. What are the safety precautions you observe while operating packing machinery?

When operating packing machinery, I prioritize safety through the following precautions:

- Proper Training: I undergo thorough training on the specific machinery I operate, ensuring I understand its functions and safety procedures.

- Protective Gear: I wear appropriate protective gear, such as gloves, safety glasses, and hearing protection, to minimize the risk of injuries.

- Safe Operating Practices: I follow established operating procedures, including starting and stopping the machinery safely, maintaining a safe distance from moving parts, and avoiding loose clothing or jewelry that could get caught.

- Regular Inspection and Maintenance: I conduct regular inspections of the machinery to identify any potential hazards or malfunctions, and I report any issues promptly for maintenance.

3. How do you maintain the quality of sugar cane stalks during packing?

To maintain the quality of sugar cane stalks during packing, I adhere to the following practices:

- Careful Handling: I handle stalks with care to avoid bruising or damage, which could compromise their integrity and reduce their economic value.

- Proper Storage: I ensure stalks are stored in a cool, dry, and well-ventilated environment to prevent spoilage or deterioration.

- Moisture Control: I manage moisture levels to prevent excessive drying or decay, which can impact the sugar content and overall quality of the stalks.

- Temperature Monitoring: I monitor the temperature of the storage area to maintain optimal conditions for preserving the stalks.

4. How do you troubleshoot common issues encountered during the packing process?

When troubleshooting common issues during the packing process, I follow a systematic approach:

- Identify the Issue: I first identify the specific problem or malfunction that is affecting the packing process.

- Examine the Cause: I examine the equipment, packaging materials, or operating procedures to determine the underlying cause of the issue.

- Implement a Solution: Based on my analysis, I implement appropriate measures to rectify the problem, such as adjusting machine settings, replacing defective parts, or modifying operating practices.

- Test the Solution: I test the implemented solution to ensure it effectively resolves the issue and does not introduce new problems.

5. How do you ensure efficient utilization of packing materials while minimizing waste?

I prioritize efficient utilization of packing materials to minimize waste through the following strategies:

- Optimized Packaging Design: I participate in designing packaging solutions that utilize materials effectively, reduce void spaces, and minimize the overall amount of materials required.

- Material Selection: I choose packing materials that are durable, reusable, or biodegradable to reduce waste and promote sustainability.

- Proper Storage and Handling: I store and handle packing materials properly to prevent damage or deterioration, ensuring they can be reused multiple times.

- Waste Reduction Initiatives: I participate in waste reduction initiatives, such as recycling or composting programs, to minimize the environmental impact of discarded materials.

6. How do you manage and maintain a clean and organized packing area?

Maintaining a clean and organized packing area is crucial to ensure efficiency, safety, and product quality:

- Regular Cleaning: I perform regular cleaning tasks, including sweeping, mopping, and disinfecting surfaces, to remove dirt, debris, and potential contaminants.

- Organized Storage: I organize packing materials, equipment, and supplies in designated areas to minimize clutter and ensure easy access.

- Waste Management: I implement a waste management system to promptly dispose of packing waste, preventing accumulation and maintaining a hygienic work environment.

- Preventive Maintenance: I conduct regular maintenance checks to identify and fix any potential issues that could lead to accidents or equipment breakdowns, ensuring a safe and efficient working area.

7. How do you prioritize and manage multiple tasks during peak packing seasons?

During peak packing seasons, I prioritize and manage multiple tasks efficiently through the following strategies:

- Task Prioritization: I assess the urgency and importance of each task, focusing on completing critical tasks first to meet deadlines.

- Time Management: I allocate my time wisely, using techniques such as time blocking and to-do lists to stay organized and avoid procrastination.

- Delegation: When necessary, I delegate tasks to colleagues who have the necessary skills and experience, ensuring efficient task distribution.

- Communication: I maintain open communication with supervisors, colleagues, and customers to coordinate tasks and avoid conflicts or delays.

8. How do you stay updated on industry best practices and technological advancements in sugar cane packing?

To stay updated on industry best practices and technological advancements in sugar cane packing, I engage in the following activities:

- Attend Industry Events: I attend conferences, workshops, and trade shows to learn about new technologies and connect with industry experts.

- Read Trade Publications: I subscribe to industry magazines and journals to stay informed about the latest research, innovations, and trends.

- Online Research: I conduct online research to explore best practices, case studies, and technical articles related to sugar cane packing.

- Networking: I network with colleagues, suppliers, and other professionals in the field to exchange knowledge and ideas.

9. How do you ensure the accuracy and consistency of packing operations to meet quality standards?

To ensure the accuracy and consistency of packing operations meet quality standards, I follow these practices:

- Established Procedures: I adhere to standardized packing procedures that outline the specific steps, measurements, and quality control checks.

- Regular Calibration: I regularly calibrate packing equipment to maintain accuracy and prevent errors.

- Quality Inspections: I conduct thorough quality inspections throughout the packing process to identify and correct any deviations from established standards.

- Documentation: I maintain accurate documentation of packing operations, including packing specifications, quality control checks, and any corrective actions taken.

10. How do you handle unexpected challenges or disruptions during the packing process?

When faced with unexpected challenges or disruptions during the packing process, I respond effectively through the following steps:

- Problem Assessment: I promptly assess the situation to identify the root cause of the disruption.

- Contingency Planning: I activate contingency plans or develop alternative solutions to minimize the impact on packing operations.

- Communication: I communicate with supervisors, colleagues, and customers to inform them of the situation and coordinate efforts to resolve the issue.

- Continuous Improvement: I evaluate the incident and identify opportunities for process improvement to prevent similar disruptions in the future.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cane Packer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cane Packer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cane Packers are responsible for packing sugar cane into various containers, ensuring that they are properly filled and sealed to prevent leakage or damage during transportation. Their duties include:

1. Packing Cane

Pack sugar cane into designated containers, such as bags, boxes, or crates, according to established guidelines and specifications.

- Ensure that containers are filled to the appropriate level and securely sealed to prevent spillage or contamination.

- Inspect containers for any damages or defects that could compromise the quality or safety of the cane.

2. Loading and Unloading

Load and unload packed containers of sugar cane using manual labor or equipment, such as forklifts or conveyors.

- Follow proper lifting techniques to prevent injuries and maintain productivity.

- Operate equipment safely and efficiently to minimize downtime and ensure smooth operations.

3. Maintaining Work Area

Maintain a clean and organized work area, adhering to safety regulations and housekeeping standards.

- Dispose of waste materials properly, including empty containers and damaged cane.

- Report any potential hazards or safety concerns to supervisors or designated personnel.

4. Quality Control

Inspect packed containers of sugar cane to ensure they meet quality standards and specifications.

- Identify and remove any damaged or substandard cane to maintain product quality.

- Follow established procedures for handling and storing sugar cane to prevent spoilage or loss of value.

Interview Tips

To ace an interview for a Cane Packer position, it is crucial to be well-prepared and demonstrate your skills and qualifications. Here are some interview tips to help you succeed:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and the specific requirements of the Cane Packer role. This will demonstrate your interest and enthusiasm for the position.

- Visit the company’s website and social media pages to gather information about their operations and culture.

- Read industry publications and articles to stay updated on the latest trends and practices in sugar cane packing.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job responsibilities of a Cane Packer. Highlight your proficiency in packing and handling techniques, attention to detail, and ability to work in a physically demanding environment.

- Provide specific examples of your experience in packing and transporting sugar cane or similar products.

- Quantify your accomplishments whenever possible, using numbers to demonstrate your impact.

3. Demonstrate Physical Fitness and Endurance

The role of a Cane Packer requires physical fitness and endurance. During the interview, be prepared to discuss your ability to perform physically demanding tasks, such as lifting heavy weights and working in various weather conditions.

- Explain your fitness routine and how it prepares you for the physical demands of the job.

- Emphasize your willingness to work overtime or on weekends, if necessary.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. Prepare questions that demonstrate your understanding of the role and the company’s operations.

- Inquire about the company’s quality control standards for sugar cane packing.

- Ask about the opportunities for professional development and advancement within the organization.

Next Step:

Now that you’re armed with the knowledge of Cane Packer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Cane Packer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini