Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Canned Food Reconditioning Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Canned Food Reconditioning Inspector so you can tailor your answers to impress potential employers.

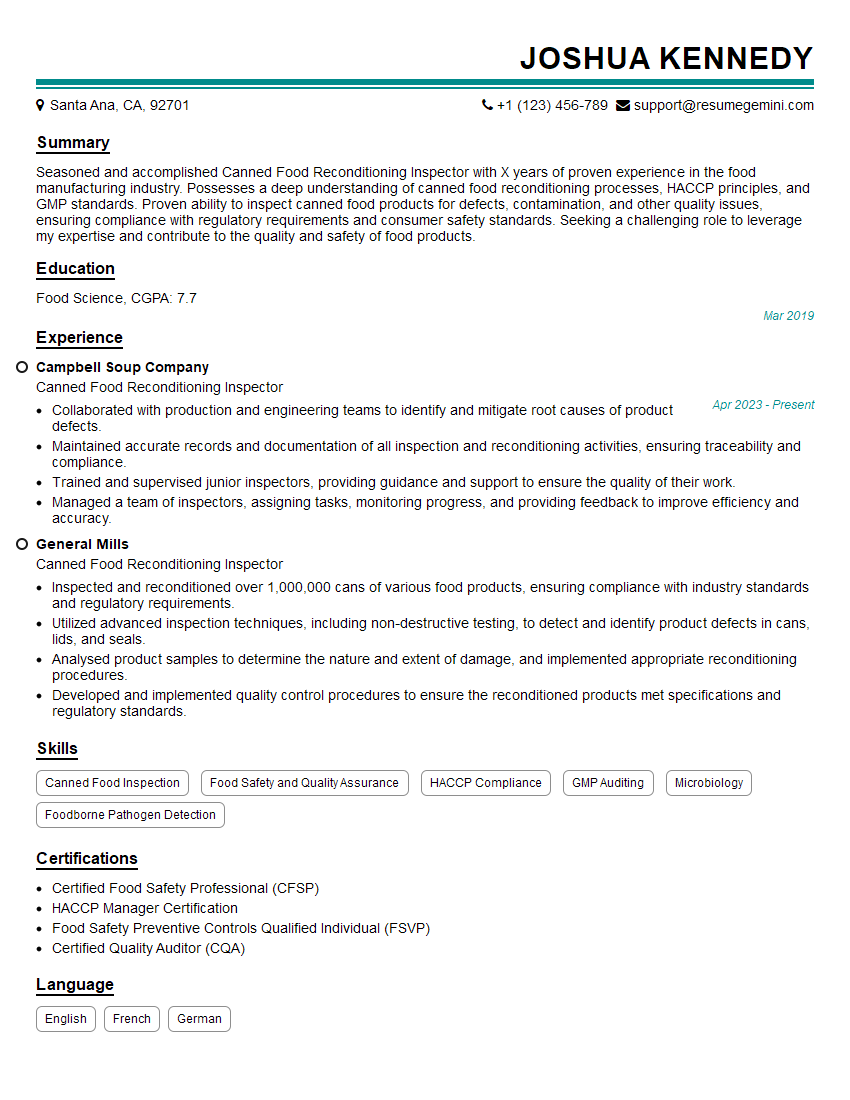

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Canned Food Reconditioning Inspector

1. What are the key responsibilities of a Canned Food Reconditioning Inspector?

As a Canned Food Reconditioning Inspector, my primary responsibilities include:

- Inspecting and grading canned food products to ensure their quality and safety.

- Examining cans for defects such as leaks, dents, or swelling.

- Assessing the condition of food products to determine if they are fit for consumption.

- Adhering to established inspection protocols and maintaining accurate records of all inspections.

- Providing feedback to the production team to improve the quality of canned food products.

2. Describe the inspection process for canned food products.

The inspection process for canned food products involves the following steps:

Receiving inspection:

- Inspecting cans for any visible damage during the receiving process.

- Checking for proper labeling and product identification.

In-process inspection:

- Monitoring the production process to ensure that cans are filled and sealed properly.

- Inspecting cans for any defects or contamination.

Finished product inspection:

- Examining finished canned products for any defects, including leaks, dents, or swelling.

- Grading products based on their quality and condition.

- Ensuring that products meet established standards and specifications.

3. What are the common defects you look for in canned food products?

Some of the common defects I look for in canned food products include:

- Leaks or punctures in the cans

- Dents or bulging in the cans

- Swelling or spoilage of the food products

- Contamination with foreign objects

- Incorrect or missing labeling information

4. How do you determine the severity of a defect?

The severity of a defect is determined based on its potential impact on the safety and quality of the canned food product. Some factors I consider include:

- The type and location of the defect

- The potential for the defect to cause contamination or spoilage

- The overall condition of the canned food product

5. What are the different grading systems used for canned food products?

There are several grading systems used for canned food products, including:

- USDA Grade Standards: Used for grading fruits, vegetables, and certain seafood products.

- FDA Grade Standards: Used for grading seafood products.

- In-house grading systems: Developed by individual companies to meet their specific quality requirements.

6. How do you maintain accurate and consistent inspection records?

I maintain accurate and consistent inspection records by:

- Using standardized inspection forms and checklists.

- Documenting all observations and findings clearly and concisely.

- Reviewing records regularly for accuracy and completeness.

- Storing records securely and in a readily accessible manner.

7. What are the challenges you face in your role as a Canned Food Reconditioning Inspector?

Some of the challenges I face in my role include:

- Ensuring the consistency and accuracy of inspections.

- Maintaining a high level of attention to detail over long periods.

- Dealing with potential safety hazards or contaminated products.

- Keeping up with changes in industry standards and regulations.

8. What are the most important qualities for a successful Canned Food Reconditioning Inspector?

The most important qualities for a successful Canned Food Reconditioning Inspector include:

- Excellent attention to detail and observational skills.

- Strong knowledge of food safety principles and regulations.

- Ability to work independently and as part of a team.

- Excellent communication and reporting skills.

- Commitment to quality and customer satisfaction.

9. What professional development opportunities have you pursued to enhance your skills as a Canned Food Reconditioning Inspector?

To enhance my skills as a Canned Food Reconditioning Inspector, I have pursued the following professional development opportunities:

- Attending industry conferences and workshops.

- Completing online courses and certifications.

- Reading trade publications and staying up-to-date with industry best practices.

- Seeking mentorship from experienced inspectors.

10. How do you stay motivated and engaged in your role as a Canned Food Reconditioning Inspector?

I stay motivated and engaged in my role by:

- Understanding the importance of my work in ensuring the safety and quality of canned food products.

- Setting personal goals and striving to continuously improve my performance.

- Collaborating with colleagues and seeking opportunities to contribute to the team.

- Taking pride in my work and seeing the positive impact it has on consumers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Canned Food Reconditioning Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Canned Food Reconditioning Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Canned Food Reconditioning Inspectors are responsible for ensuring the quality and safety of canned food products during the reconditioning process. Key job responsibilities include:

1. Inspecting Canned Food Products

Inspecting and examining canned food products for any defects, damage, or contamination. This includes checking for dents, scratches, leaks, and other physical imperfections.

- Identifying and segregating defective products for further evaluation or disposal.

- Ensuring that reconditioned products meet all quality and safety standards.

2. Evaluating Reconditioning Process

Monitoring and evaluating the reconditioning process to ensure that it is carried out according to established procedures.

- Verifying that proper equipment and techniques are used during reconditioning.

- Ensuring that reconditioned products are properly labeled and packaged.

3. Maintaining Quality Records

Maintaining accurate and detailed records of all inspections and reconditioning activities.

- Documenting the condition of products before and after reconditioning.

- Reporting any defects or non-conformances to management.

4. Troubleshooting and Problem-Solving

Troubleshooting and resolving any issues that arise during the reconditioning process.

- Identifying the root causes of defects or non-conformances.

- Developing and implementing corrective actions to prevent future problems.

Interview Tips

To ace an interview for a Canned Food Reconditioning Inspector position, it is essential to prepare thoroughly. Here are some tips to help you succeed:

1. Research the Company and Position

Research the company you are applying to and the specific role of a Canned Food Reconditioning Inspector. This will help you understand their values, mission, and the key responsibilities of the position.

- Visit the company’s website and review their products, services, and recent news.

- Read online reviews and articles about the company to gain insights into their culture and reputation.

2. Highlight Your Experience and Skills

Emphasize your experience and skills that are relevant to the job requirements. Focus on your knowledge of food safety regulations, quality control procedures, and reconditioning techniques.

- Provide specific examples of your work experience where you have successfully inspected, evaluated, and reconditioned canned food products.

- Quantify your accomplishments whenever possible, using specific metrics or data.

3. Demonstrate Your Attention to Detail

Canned Food Reconditioning Inspectors must have a keen eye for detail and the ability to identify even minor defects or non-conformances. In the interview, showcase your attention to detail by:

- Describing specific instances where you identified and resolved defects in canned food products.

- Explaining your techniques for thoroughly inspecting and evaluating products.

4. Practice Your Communication Skills

Effective communication is essential for a Canned Food Reconditioning Inspector. Be prepared to articulate your findings clearly and concisely to management, production staff, and customers.

- Practice your communication skills by preparing answers to common interview questions.

- Consider role-playing scenarios where you have to report defects or non-conformances.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Canned Food Reconditioning Inspector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.