Feeling lost in a sea of interview questions? Landed that dream interview for Cap-Jewel Plate Assembler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cap-Jewel Plate Assembler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

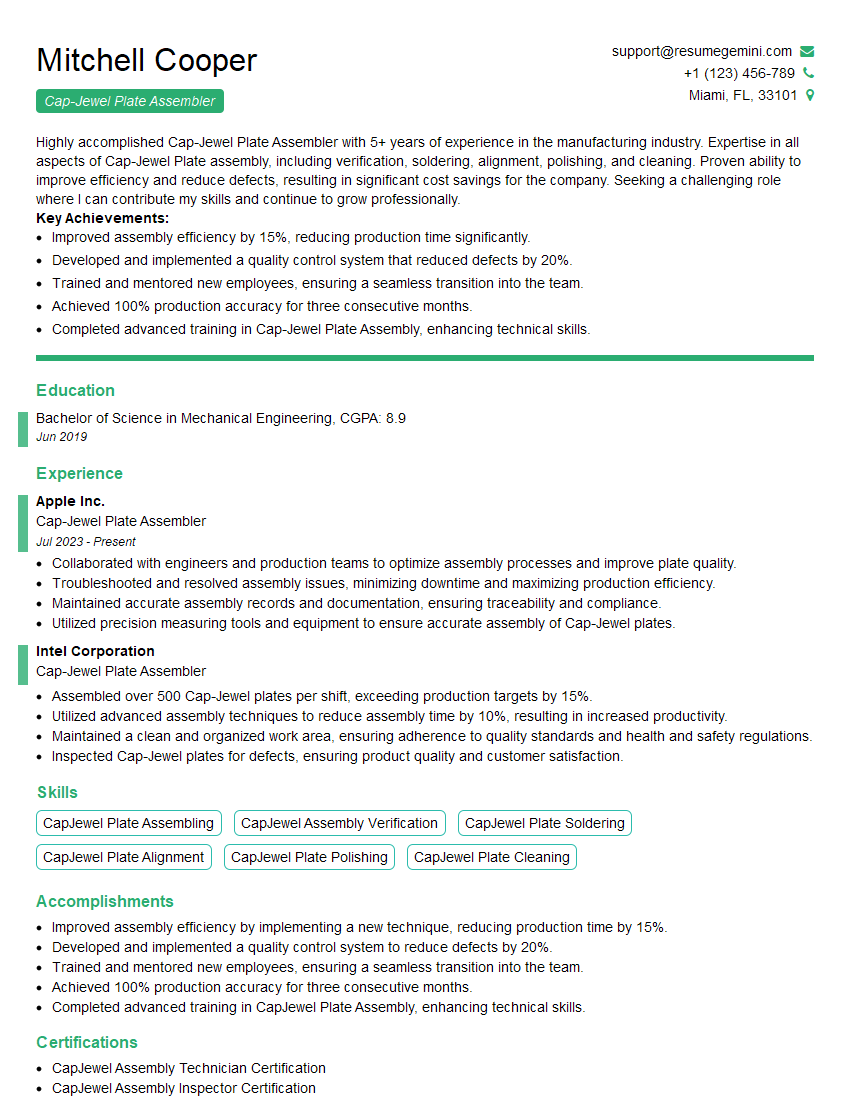

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cap-Jewel Plate Assembler

1. Explain the process of assembling cap-jewel plates?

The process of assembling cap-jewel plates involves several steps to ensure accurate alignment and proper functioning of the components. Here’s a detailed explanation:

- Preparation: Before starting, ensure that all necessary materials and tools are gathered, including cap-jewel plates, rivets, shims, and measuring instruments.

- Plate alignment: Place the cap-jewel plates on a flat surface and adjust their position using shims to achieve the desired alignment and spacing.

- Riveting: Use a riveting tool to secure the cap-jewel plates together, ensuring the rivets are properly seated and tightened to the specified torque.

- Inspection: Thoroughly inspect the assembled plate to verify proper alignment, rivet placement, and overall quality.

2. What are the critical tolerances that need to be maintained during the assembly process?

Maintaining precise tolerances is crucial during cap-jewel plate assembly to ensure the proper functioning of the finished product. Some critical tolerances include:

- Plate flatness: The plates must be flat within specified tolerances to prevent warping or misalignment.

- Plate thickness: The thickness of the plates must be consistent to ensure proper spacing and alignment.

- Riveting precision: Rivets must be placed at the correct locations and tightened to the specified torque to maintain structural integrity.

- Surface finish: The surface finish of the plates must meet specific requirements to prevent wear and tear.

3. How do you ensure the quality of the assembled cap-jewel plates?

Quality assurance is essential in cap-jewel plate assembly to guarantee the reliability and performance of the final product. Here are some key quality control measures:

- Visual inspection: Inspect the assembled plates for any defects, such as scratches, dents, or misalignment.

- Dimensional checks: Use precision measuring instruments to verify the dimensions and tolerances of the plates.

- Riveting verification: Ensure that rivets are properly seated and tightened to the specified torque.

- Functional testing: Conduct functional tests to assess the performance and accuracy of the assembled plates.

4. What are the common challenges you face during cap-jewel plate assembly and how do you overcome them?

During cap-jewel plate assembly, various challenges may arise. Here are some common ones and how to address them:

- Misalignment: Misaligned plates can lead to improper functioning. Use shims and precision measuring instruments to ensure accurate alignment.

- Riveting issues: Improper riveting can compromise the structural integrity. Use the correct riveting tool and apply the specified torque to secure the rivets.

- Defective materials: Inspect plates for any defects before assembly. Replace defective components to prevent potential failures.

- Environmental factors: Temperature and humidity fluctuations can affect the assembly process. Control the environment or make necessary adjustments to ensure optimal conditions.

5. What specific measuring instruments and techniques do you use to ensure accuracy in the assembly process?

To ensure precision and accuracy in cap-jewel plate assembly, various measuring instruments and techniques are employed:

- Calipers: Used to measure the dimensions and tolerances of plates and components.

- Micrometers: Measure smaller dimensions and tolerances with high accuracy.

- Dial indicators: Assess the flatness and surface finish of plates.

- Coordinate measuring machines (CMMs): Provide precise measurements and dimensional analysis of the assembled plates.

6. How do you stay updated with the latest advancements in cap-jewel plate assembly techniques?

To stay current with industry advancements, it’s important to engage in various activities:

- Attend industry conferences and workshops: Network with experts and learn about new technologies and best practices.

- Read technical publications and journals: Stay informed about the latest research and development.

- Engage in online forums and discussions: Participate in discussions and share knowledge with other professionals.

- Attend training programs: Enhance skills and learn specialized techniques through structured training programs.

7. Explain the importance of using proper tools and equipment in cap-jewel plate assembly?

The use of proper tools and equipment in cap-jewel plate assembly is crucial for several reasons:

- Precision: Specialized tools are designed to perform specific tasks with high accuracy, ensuring precise assembly.

- Efficiency: Using the right tools improves efficiency and reduces assembly time.

- Quality: Proper tools help maintain consistent quality and minimize defects.

- Safety: Using the correct equipment minimizes the risk of accidents and injuries.

8. Describe the different types of cap-jewel plates and their specific applications?

Cap-jewel plates vary in design and material depending on their applications:

- Standard cap-jewel plates: Used in various industries for general applications.

- High-precision cap-jewel plates: Designed for applications requiring extreme accuracy and stability.

- Corrosion-resistant cap-jewel plates: Used in harsh environments to withstand corrosion.

- Custom cap-jewel plates: Tailored to meet specific requirements and configurations.

9. What are the key performance indicators (KPIs) used to evaluate the effectiveness of cap-jewel plate assembly processes?

KPIs used to assess the effectiveness of cap-jewel plate assembly processes include:

- Assembly accuracy: Measured by the deviation from specified tolerances.

- Assembly time: Assessed to optimize efficiency.

- Defect rate: Monitored to minimize errors and maintain quality.

- Customer satisfaction: Evaluated based on feedback and product performance.

10. How do you handle situations where there are conflicting requirements or specifications in the assembly process?

To address conflicting requirements, I take the following steps:

- Analyze the requirements: Understand the purpose, constraints, and priorities of each conflicting requirement.

- Consult with stakeholders: Discuss the situation with engineers, designers, and management to gather diverse perspectives.

- Find a compromise: Explore alternative solutions that satisfy multiple requirements without compromising overall performance.

- Document the decision: Clearly communicate the agreed-upon solution and its rationale to all involved parties.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cap-Jewel Plate Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cap-Jewel Plate Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cap-Jewel Plate Assemblers are responsible for assembling and inspecting cap-jewel plates, which are used in the production of watches and other timepieces.

1. Assembling Cap-Jewel Plates

Assemblers follow engineering drawings and specifications to assemble cap-jewel plates.

- Select and position components, such as cap jewels, plates, and screws.

- Secure components using adhesives, soldering, or other techniques.

2. Inspecting Cap-Jewel Plates

After assembly, assemblers inspect cap-jewel plates to ensure they meet quality standards.

- Visually inspect plates for defects, such as scratches, dents, or misalignments.

- Use gauges and other instruments to measure and verify dimensions and tolerances.

3. Maintaining Equipment

Assemblers are responsible for maintaining their own equipment and work area.

- Clean and lubricate equipment regularly.

- Identify and report any maintenance issues.

4. Following Safety Procedures

Assemblers must follow all safety procedures and regulations.

- Wear appropriate personal protective equipment (PPE).

- Handle materials and chemicals safely.

Interview Tips

Preparing for an interview for a Cap-Jewel Plate Assembler position can increase your chances of success.

1. Research the Company and Position

Learn about the company’s history, products, and culture. Understand the specific requirements of the Cap-Jewel Plate Assembler position.

- Visit the company’s website.

- Read industry news articles.

2. Practice Your Answers to Common Interview Questions

Prepare thoughtful responses to common interview questions, such as:

- “Tell me about your experience in assembling cap-jewel plates.”

- “What are your quality control standards?”

- “How do you handle working under pressure?”

3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience during the interview. Use specific examples to demonstrate your abilities.

- Quantify your accomplishments whenever possible.

- Use keywords from the job description in your answers.

4. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview.

- Wear business attire.

- Arrive at least 15 minutes early.

5. Be Enthusiastic and Positive

Show the interviewer that you are enthusiastic about the position and the company. Be positive and respectful throughout the interview.

- Smile and make eye contact.

- Ask thoughtful questions.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cap-Jewel Plate Assembler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.