Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Capacitor Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

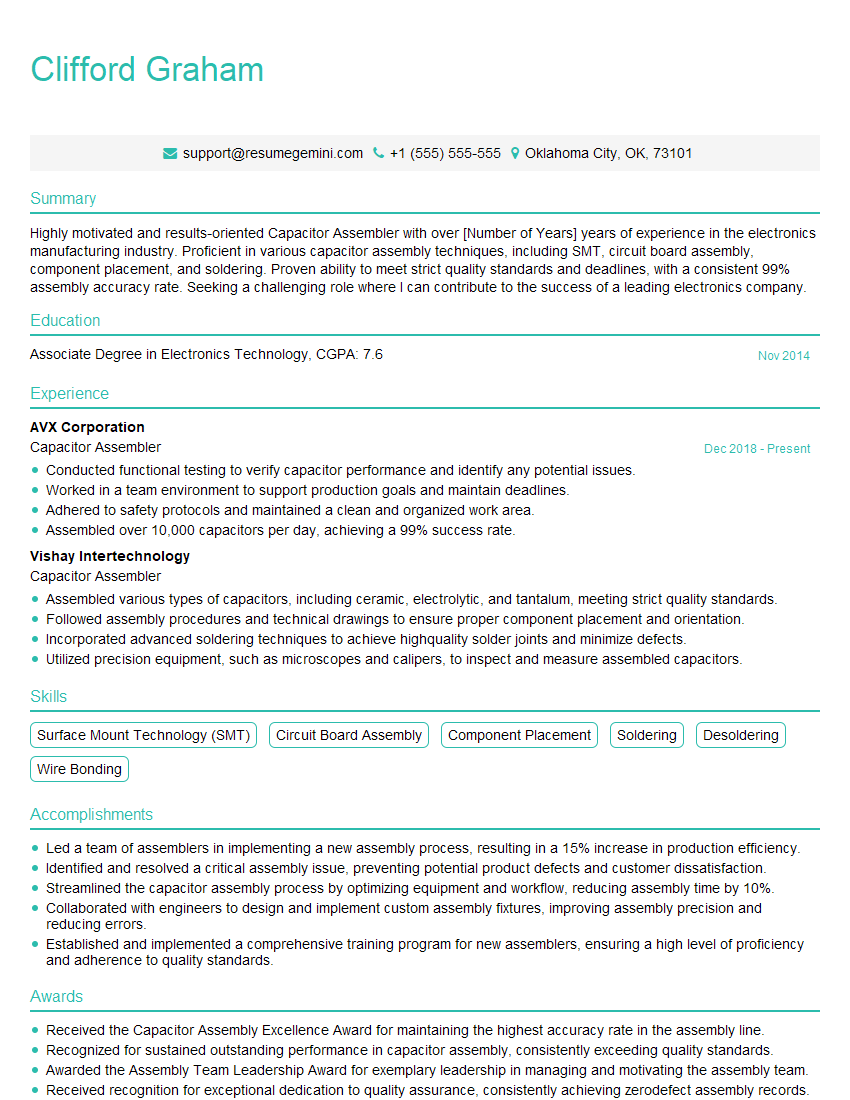

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Capacitor Assembler

1. What are the different types of capacitors and their applications?

There are various types of capacitors, each with its unique characteristics and applications:

- Ceramic capacitors: Known for their small size, high capacitance, and low cost. Used in electronic devices like smartphones and computers.

- Electrolytic capacitors: Have higher capacitance values and are polarized, meaning they have a positive and negative terminal. Used in power supplies and audio amplifiers.

- Film capacitors: Made from thin layers of plastic film and metal foil, offering high stability and low losses. Used in high-frequency applications.

- Tantalum capacitors: Compact and have high capacitance values, but are more expensive than other types. Used in portable electronics.

- Supercapacitors: Offer extremely high capacitance values and can store large amounts of energy. Used in electric vehicles and backup power systems.

2. Describe the process of capacitor assembly.

Materials Preparation:

- Gather necessary materials, including capacitor plates, dielectric material, and terminals.

- Inspect materials for defects or damage.

Assembly:

- Align and separate capacitor plates using the dielectric material.

- Connect terminals to the capacitor plates.

- Enclose the capacitor assembly in a housing or case.

Quality Control:

- Perform electrical tests to verify capacitance and other specifications.

- Inspect the capacitor for any physical defects.

3. What are the common defects in capacitors and how do you detect them?

Capacitor defects can include:

- Short circuits: Direct electrical connection between capacitor plates, which can be detected by low capacitance readings.

- Open circuits: Broken connection between capacitor plates or terminals, which can be detected by infinite capacitance readings.

- Leakage current: Undesirable current flow between capacitor plates, which can be detected by measuring the capacitor’s resistance.

- Capacitance drift: Change in capacitance over time, which can be detected by comparing capacitance readings over time.

- Physical defects: Cracks, dents, or other physical damages that can affect the capacitor’s performance.

4. How do you ensure the quality of assembled capacitors?

To ensure quality, I would implement the following measures:

- Material inspection: Inspect incoming materials for defects or damage.

- Process control: Adhere to established assembly procedures and maintain proper equipment calibration.

- In-process testing: Perform electrical tests during the assembly process to identify any potential defects.

- Final inspection: Conduct a thorough physical and electrical inspection of finished capacitors before packaging.

- Quality control records: Maintain documentation of all quality control measures and test results.

5. What safety precautions should be taken when working with capacitors?

To ensure safety when working with capacitors, I would prioritize the following precautions:

- Discharge capacitors: Before handling or testing capacitors, discharge them using appropriate methods to prevent electrical shocks.

- Wear protective gear: Use insulated gloves and safety glasses to minimize the risk of electrical injuries.

- Handle capacitors with care: Avoid touching capacitor terminals or exposed metal parts to prevent short circuits.

- Store capacitors properly: Store capacitors in a safe and dry location to prevent damage or deterioration.

- Dispose of capacitors responsibly: Follow proper disposal procedures to avoid environmental contamination.

6. How do you maintain and calibrate the equipment used in capacitor assembly?

To maintain and calibrate equipment, I would establish a regular maintenance schedule, including the following steps:

- Equipment inspection: Regularly inspect equipment for any signs of wear or damage.

- Calibration: Use certified standards to calibrate measuring and testing equipment according to established procedures.

- Preventive maintenance: Perform routine maintenance tasks, such as cleaning, lubrication, and adjustment, to prevent equipment failures.

- Maintenance records: Keep detailed records of all maintenance and calibration activities.

- Training: Ensure that staff is properly trained on the use and maintenance of equipment.

7. Describe your experience in troubleshooting capacitor assembly issues.

In my previous role as a Capacitor Assembler, I encountered various assembly issues and resolved them through the following steps:

- Identify the issue: Analyze the capacitor’s performance, specifications, and assembly process to determine the root cause.

- Investigate possible causes: Consider potential defects in materials, assembly errors, or equipment malfunctions.

- Test and verify: Perform electrical tests and inspections to confirm the issue and eliminate other factors.

- Implement corrective actions: Repair or replace defective components, adjust assembly procedures, or calibrate equipment as necessary.

- Monitor and evaluate: Track the capacitor’s performance after troubleshooting to ensure the issue has been resolved.

8. What is the role of a Capacitor Assembler in the manufacturing process?

The Capacitor Assembler plays a crucial role in the manufacturing process by:

- Assembling capacitors: Following established procedures to assemble various types of capacitors.

- Ensuring quality: Performing electrical tests and inspections to verify the performance and reliability of assembled capacitors.

- Troubleshooting: Identifying and resolving assembly issues, such as defects or equipment malfunctions.

- Maintaining equipment: Keeping assembly equipment in good working order to ensure accurate and efficient capacitor production.

- Contributing to process improvement: Participating in discussions and providing suggestions to enhance the capacitor assembly process.

9. How do you stay updated on the latest advancements in capacitor technology?

To stay current with advancements in capacitor technology, I engage in the following practices:

- Attend industry conferences and workshops: Participate in events where experts share knowledge and showcase new technologies.

- Read technical publications and journals: Stay informed about the latest research, developments, and applications.

- Network with professionals: Connect with other Capacitor Assemblers and industry experts to exchange ideas and learn from their experiences.

- Explore online resources: Utilize websites, databases, and online forums to access technical information and updates.

- Seek opportunities for training and certification: Enhance my skills and knowledge through certification programs or specialized training.

10. What are your career goals and how does this position align with them?

My career goal is to become a skilled and experienced Capacitor Assembler, contributing to the advancement of electronics manufacturing. This position aligns with my goals by providing me with the opportunity to:

- Gain practical experience: Enhance my hands-on skills in capacitor assembly and quality control.

- Contribute to team success: Collaborate with colleagues and contribute to the efficient and effective production of high-quality capacitors.

- Develop my technical knowledge: Access resources and mentorship to stay updated on the latest capacitor technologies and industry best practices.

- Build a strong foundation: Establish a solid foundation in capacitor assembly, paving the way for future career growth and specialization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Capacitor Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Capacitor Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Capacitor Assemblers perform a range of duties related to the assembly, testing, and packaging of capacitors. Their responsibilities include:

1. Capacitor Manufacturing Techniques

Performing various tasks involved in the manufacturing of capacitors, such as winding, welding, soldering, and insulating.

- Winding: Using winding machines to wrap conductive materials around a core to create coils.

- Welding: Joining metal components using welding techniques to ensure electrical conductivity.

- Soldering: Connecting electrical components using solder to create secure and conductive joints.

- Insulating: Applying insulating materials to protect capacitors from electrical shorts and ensure safe operation.

2. Quality Control and Testing

Conducting quality control checks and testing procedures to ensure the accuracy and reliability of manufactured capacitors.

- Visual inspection: Examining capacitors for defects, such as cracks, misalignments, or improper assembly.

- Electrical testing: Using specialized equipment to measure electrical parameters, such as capacitance, resistance, and voltage withstand.

- Environmental testing: Exposing capacitors to different environmental conditions, such as temperature, humidity, and vibration, to ensure durability.

3. Production Line Monitoring

Monitoring production lines to ensure smooth operation and identify potential issues. Responding to alarms, resolving problems, and implementing corrective actions.

- Monitoring equipment: Observing machines and equipment for proper functioning and identifying any malfunctions.

- Responding to alarms: Reacting promptly to production line alarms and taking appropriate measures to address the issue.

- Problem-solving: Identifying and analyzing production issues, determining root causes, and implementing solutions to prevent recurrence.

4. Ensuring Compliance with Safety Regulations

Complying with established safety regulations and policies to maintain a safe working environment. Using personal protective equipment (PPE) and adhering to safety protocols.

- Following safety protocols: Adhering to prescribed safety guidelines and procedures to minimize risks and prevent accidents.

- Using PPE: Wearing appropriate personal protective equipment, such as gloves, safety glasses, and earplugs, to protect themselves from potential hazards.

- Maintaining a clean and organized workspace: Keeping the work area tidy and free of clutter to prevent tripping hazards and accidents.

Interview Tips

Preparing for an interview for a Capacitor Assembler position requires a combination of technical knowledge and preparation strategies. Here are some tips to help candidates ace their interview:

1. Research the Company and Industry

Gather information about the company, its products, and the capacitor industry. This will demonstrate your interest and understanding of the role and the organization.

- Visit the company website and social media pages.

- Read articles and news about the industry and capacitor technology.

- Connect with current or former employees on LinkedIn.

2. Highlight Your Technical Skills

Emphasize your proficiency in capacitor manufacturing techniques, quality control procedures, and production line monitoring. Quantify your experience and provide specific examples of your work.

- Describe your experience in winding, welding, soldering, and insulating capacitors.

- Explain your knowledge of electrical testing methods and environmental testing procedures.

- Share examples of how you implemented corrective actions to improve production efficiency or product quality.

3. Demonstrate Safety Consciousness

Stress your commitment to safety by discussing your adherence to safety regulations and your use of personal protective equipment. Provide examples of how you maintained a safe work environment.

- Explain your understanding of industry safety standards and best practices.

- Describe how you regularly inspect equipment and follow safety protocols.

- Share an example of a time when you identified a potential hazard and took proactive measures to address it.

4. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers in advance. This will help you feel more confident and articulate during the actual interview.

- Tell me about your experience in capacitor manufacturing.

- Describe your quality control process for ensuring capacitor quality.

- How do you handle production line issues and ensure efficiency?

- What are your key strengths and weaknesses as a Capacitor Assembler?

- Why are you interested in this position and our company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Capacitor Assembler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.