Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Capper Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

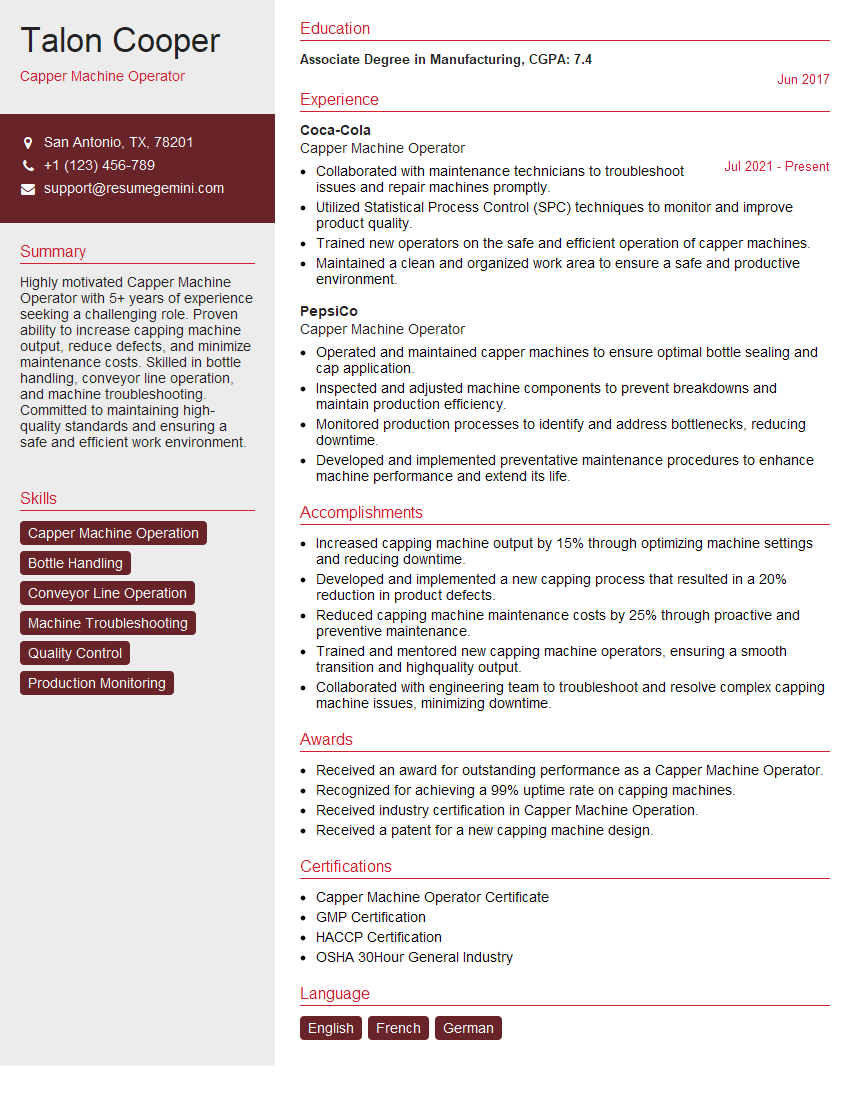

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Capper Machine Operator

1. Describe the process of setting up a capper machine for a new product run.

The setup process for a new product run on a capper machine typically involves the following steps:

- Gather the necessary materials, including the new product, caps, and any other required components.

- Clean and inspect the capper machine to ensure that it is in good working order.

- Adjust the machine settings to accommodate the new product and cap size.

- Load the product and caps into the machine.

- Run a test batch to verify that the machine is functioning properly.

2. What are the most common problems that can occur with capper machines, and how do you troubleshoot them?

Mechanical problems:

- Leaking or jammed parts

- Malfunctioning sensors

- Electrical issues

Operator errors:

- Incorrectly loading the product or caps

- Using the wrong settings

- Failing to maintain the machine properly

Troubleshooting:

- Inspect the machine for any visible damage or leaks.

- Check the sensor connections and ensure that they are secure.

- Verify that the electrical components are functioning properly.

- Review the machine settings and make sure that they are correct for the product being run.

- Clean and lubricate the machine regularly.

3. What are the safety procedures that must be followed when operating a capper machine?

- Always wear appropriate safety gear, including gloves, safety glasses, and a hairnet.

- Do not operate the machine if you are not trained to do so.

- Keep your hands clear of the moving parts of the machine.

- Never reach into the machine while it is running.

- Be aware of your surroundings and be careful not to trip or fall.

- Report any accidents or injuries to your supervisor immediately.

4. What are the different types of caps that can be used with a capper machine, and what are the advantages and disadvantages of each?

Crown caps:

- Advantages: Low cost, easy to apply, tamper-evident

- Disadvantages: Can be difficult to remove, not as secure as other cap types

Lug caps:

- Advantages: Secure, tamper-evident, easy to remove

- Disadvantages: More expensive than crown caps

Twist-off caps:

- Advantages: Easy to remove, tamper-evident

- Disadvantages: Can be difficult to apply, not as secure as other cap types

5. What are the different types of capper machines, and what are the advantages and disadvantages of each?

Rotary cappers:

- Advantages: High speed, efficient

- Disadvantages: Complex to operate, expensive

Inline cappers:

- Advantages: Simple to operate, less expensive than rotary cappers

- Disadvantages: Lower speed, less efficient

Semi-automatic cappers:

- Advantages: Can be used for a variety of products and cap types, flexible

- Disadvantages: Slower than automatic cappers

6. What are the maintenance procedures that must be performed on a capper machine?

- Clean the machine daily, or more often if necessary.

- Inspect the machine for any damage or wear and tear.

- Lubricate the moving parts of the machine regularly.

- Calibrate the machine regularly to ensure accuracy.

- Perform a complete overhaul of the machine annually.

7. What are the quality control procedures that must be followed when operating a capper machine?

- Inspect the product and caps before running them through the machine.

- Monitor the machine during operation to ensure that it is functioning properly.

- Inspect the finished product to ensure that it is properly capped.

- Keep records of all quality control checks.

8. What are the different ways to increase the efficiency of a capper machine?

- Use the correct cap size for the product.

- Adjust the machine settings to optimize performance.

- Keep the machine clean and well-maintained.

- Use automation to reduce manual labor.

9. What are the different ways to reduce the waste produced by a capper machine?

- Use recyclable or biodegradable caps.

- Minimize the amount of product lost during capping.

- Dispose of waste materials properly.

10. What are the latest trends in capper machine technology?

- Increased use of automation

- Development of more sustainable capping solutions

- Integration of new technologies such as IoT and AI

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Capper Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Capper Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Capper Machine Operators are responsible for the efficient operation and maintenance of capper machines, which are used to seal caps onto bottles or other containers.

1. Machine Setup and Operation

Setting up and operating capper machines, including loading and unloading materials and adjusting settings.

- Operating capper machines to seal caps onto bottles or other containers.

- Loading and unloading materials, such as bottles and caps.

- Adjusting machine settings, such as speed and pressure, to ensure optimal performance.

2. Quality Control

Ensuring the quality of capped products by inspecting and testing them.

- Inspecting capped products for defects, such as leaks and misaligned caps.

- Conducting tests, such as pressure tests, to ensure the integrity of capped products.

- Identifying and resolving issues that affect the quality of capped products.

3. Machine Maintenance

Performing basic maintenance on capper machines, such as cleaning and lubricating components.

- Cleaning and lubricating capper machines, such as conveyors and capping heads.

- Inspecting machines for wear and tear, and reporting any issues to supervisors.

- Performing minor repairs, such as replacing worn parts.

4. Safety and Compliance

Ensuring safety and compliance with all applicable regulations and procedures.

- Following all safety procedures, such as wearing appropriate protective gear.

- Complying with all applicable regulations and standards, such as those related to food safety.

- Reporting any safety hazards or concerns to supervisors.

Interview Tips

To prepare for an interview for a Capper Machine Operator position, it is important to have a thorough understanding of the key job responsibilities and how to perform them effectively.

1. Research the Company and Position

Research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and expectations for the role.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on the latest trends and technologies.

- Network with people who work in the industry or at the company.

2. Practice Your Answers

Practice answering common interview questions. This will help you feel more confident and prepared during the interview.

- Prepare answers to questions about your experience, skills, and qualifications.

- Practice answering behavioral questions, such as “Tell me about a time when you had to overcome a challenge.”.

- Rehearse your answers with a friend, family member, or career counselor.

3. Dress Professionally

Dress professionally for your interview. This shows that you are taking the interview seriously.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Choose comfortable shoes that you can walk in easily.

4. Be Enthusiastic and Positive

Be enthusiastic and positive during your interview. This will show that you are excited about the opportunity and that you are a team player.

- Smile and make eye contact with the interviewer.

- Be polite and respectful, even if you do not get the job.

- Thank the interviewer for their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Capper Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!