Are you gearing up for a career in Capping Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Capping Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

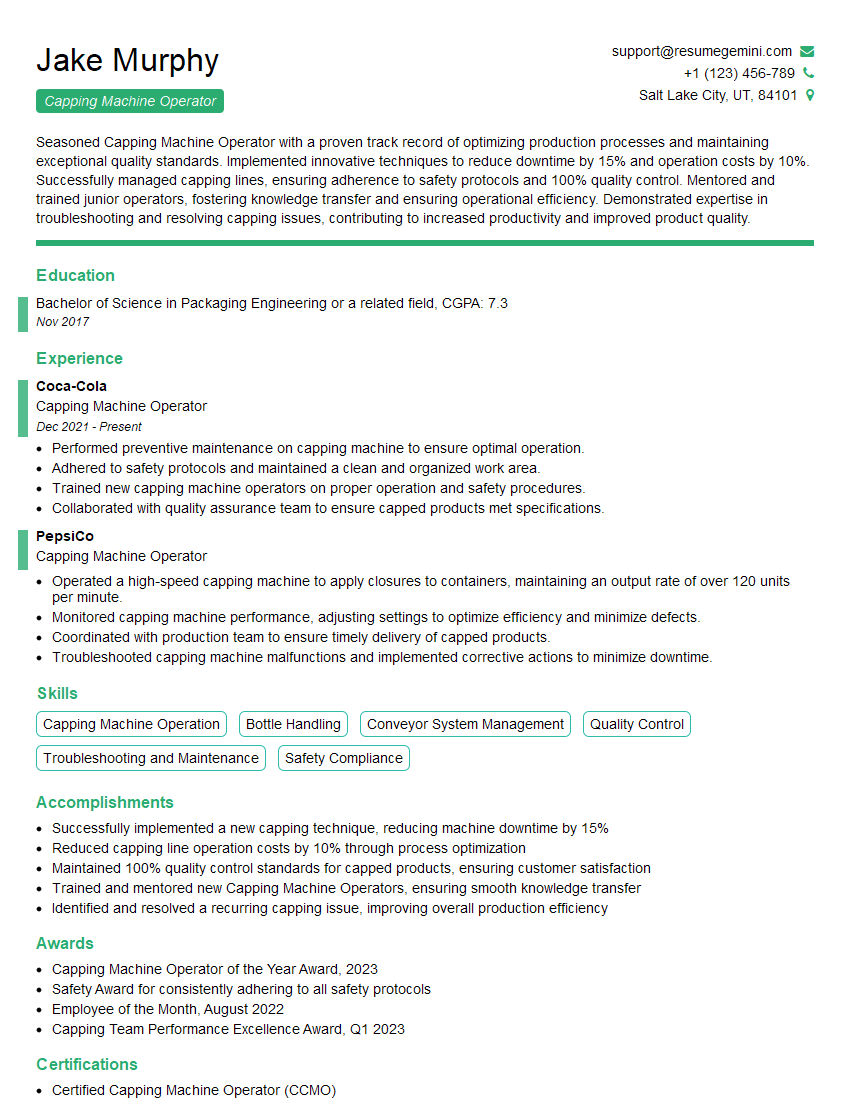

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Capping Machine Operator

1. What are the key responsibilities of a Capping Machine Operator?

As a Capping Machine Operator, my duties involve ensuring the efficient operation, maintenance, and monitoring of capping machines.

- Set up, operate, and monitor capping machines to apply caps securely and accurately onto containers

- Inspect containers and caps before capping to ensure proper fit and quality

- Adjust machine settings and troubleshoot any operational issues

- Maintain a clean and safe work environment

- Monitor production output and ensure quality standards are met

2. Describe the different types of capping machines you have experience with.

Semi-automatic Capping Machines

- Manually load containers onto the machine

- Activate the capping cycle using a foot pedal or button

Automatic Capping Machines

- Containers are automatically fed into the machine

- Caps are automatically placed and tightened onto containers

Specialty Capping Machines

- Designed for specific cap types or container shapes

- May require specialized training to operate

3. What are some common problems you have encountered with capping machines and how did you resolve them?

- Misaligned caps: Adjusted machine settings or replaced worn parts

- Loose caps: Tightened torque settings or inspected for damaged caps

- Clogged cap chute: Cleared chute and inspected for damaged caps or foreign objects

- Electrical faults: Followed troubleshooting procedures and contacted maintenance personnel if necessary

- Machine jams: Identified and removed jammed containers or caps

4. How do you ensure the quality of capped containers?

- Visually inspect containers and caps before capping

- Monitor capping machine performance to ensure consistent torque and alignment

- Conduct random quality checks throughout the production run

- Maintain accurate records of production data and quality inspections

5. What are some safety precautions you take when operating capping machines?

- Wear appropriate safety gear, including gloves and eye protection

- Operate machines only when authorized and trained

- Keep work area clean and free of tripping hazards

- Lock out and tag out machines before performing maintenance or cleaning

- Follow established safety protocols and procedures

6. Describe your experience with troubleshooting and maintaining capping machines.

- Utilized troubleshooting guides and manuals to diagnose problems

- Performed routine maintenance tasks, such as cleaning, lubrication, and filter replacement

- Identified and replaced worn or damaged parts

- Collaborated with maintenance personnel for complex repairs or upgrades

7. How do you stay up-to-date with advancements in capping technology?

- Attend industry conferences and workshops

- Read trade publications and technical journals

- Consult with equipment manufacturers and suppliers

- Participate in online forums and discussion groups

8. What are some of your strengths as a Capping Machine Operator?

- Exceptional attention to detail and accuracy

- Strong mechanical aptitude and problem-solving skills

- Ability to work independently and as part of a team

- Commitment to maintaining high quality standards

- Excellent communication and interpersonal skills

9. What are some areas where you would like to improve as a Capping Machine Operator?

- Gain experience with more advanced capping technologies

- Enhance troubleshooting skills for complex machine issues

- Develop a deeper understanding of packaging industry best practices

10. How do you handle working in a fast-paced and demanding production environment?

- Remain calm and focused under pressure

- Prioritize tasks effectively and manage time wisely

- Communicate clearly and collaborate with colleagues to resolve issues

- Maintain a positive attitude and adapt to changing demands

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Capping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Capping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of Capping Machine Operator

Capping Machine Operators play a crucial role in the packaging process, ensuring that containers are securely closed to protect their contents. Their primary responsibilities include:1. Machine Operation and Maintenance

Operate capping machines precisely, ensuring efficient and accurate capping of containers.

- Set up and adjust capping machines according to product specifications.

- Monitor machine performance, identify malfunctions, and perform basic repairs.

2. Quality Control and Inspection

Inspect capped containers to ensure proper capping, seal integrity, and product quality.

- Conduct visual inspections for leaks, damage, or misalignment.

- Use gauges or other equipment to verify torque and seal tightness.

3. Production Efficiency

Maintain high production rates while adhering to safety regulations and quality standards.

- Troubleshoot equipment issues promptly to minimize downtime.

- Follow established work procedures and maintain a clean work area.

4. Housekeeping and Sanitation

Maintain a clean and safe work environment to prevent contamination and ensure compliance.

- Clean and sanitize machines and work surfaces regularly.

- Dispose of waste materials properly and adhere to hygiene protocols.

Interview Preparation Tips for Capping Machine Operators

To ace the interview, candidates should prepare thoroughly and showcase their relevant skills and experience. Here are some invaluable tips:1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and the specific role you’re applying for. This knowledge will enable you to demonstrate your understanding and interest.

2. Practice Common Interview Questions

Prepare for commonly asked interview questions related to your experience, skills, and motivation. Practice answering them clearly and concisely, using specific examples to support your claims.

3. Highlight Relevant Experience

Emphasize your previous experience in operating capping machines, including the types of machines you’ve worked with and the products you’ve capped. Quantify your accomplishments whenever possible, using metrics to demonstrate your impact.

4. Demonstrate Attention to Detail

Capping Machine Operators must have a keen eye for detail and a commitment to quality. Highlight your ability to identify defects, maintain accuracy, and adhere to strict specifications.

5. Show Safety Consciousness

Safety is paramount in this industry. Emphasize your knowledge of safety regulations, your commitment to following protocols, and your experience in maintaining a safe work environment.

6. Be Prepared to Discuss Maintenance and Troubleshooting

Interviewers may ask about your experience in maintaining and troubleshooting capping machines. Showcase your understanding of common issues, your ability to diagnose problems, and your solutions to ensure efficient production.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Capping Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.