Are you gearing up for an interview for a Capsule Inspector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Capsule Inspector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

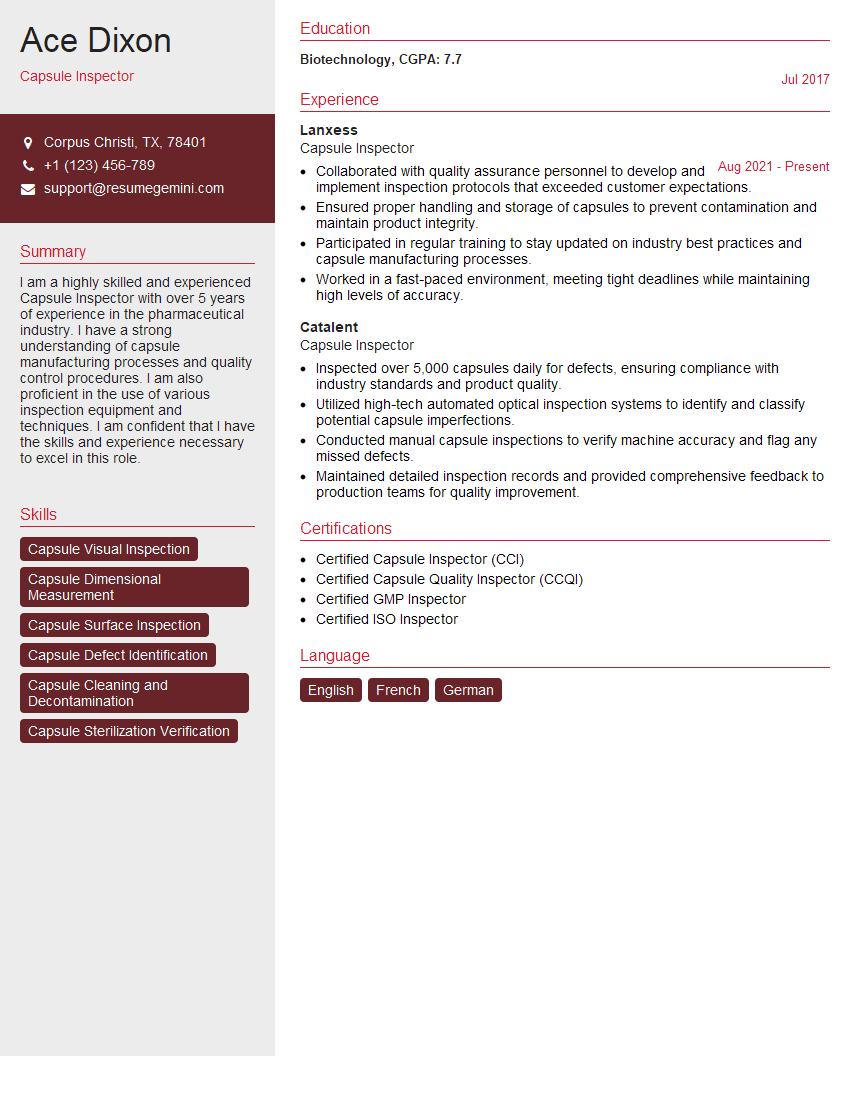

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Capsule Inspector

1. What are the different types of capsules that you are responsible for inspecting?

As a Capsule Inspector, I am responsible for inspecting various types of capsules used in the pharmaceutical industry, such as:

- Hard gelatin capsules

- Soft gelatin capsules

- Vegetable capsules

- Modified-release capsules

- Enteric-coated capsules

2. Describe the process you follow for capsule inspection.

Visual inspection

- Examine capsules for any defects, such as cracks, dents, or imperfections

- Check for proper size and shape

- Inspect for discoloration or contamination

Physical inspection

- Measure capsule thickness and weight

- Test capsule disintegration and dissolution times

- Check for capsule moisture content

3. What are the common defects you look for in capsules?

Some common defects I look for in capsules include:

- Cracks or splits in the capsule shell

- Dents or deformation in the capsule shape

- Imperfections or bubbles in the capsule material

- Discoloration or contamination on the capsule surface

- Incorrect size or shape of the capsule

4. What equipment do you use for capsule inspection?

I typically use various equipment for capsule inspection, including:

- Magnifying glass or microscope for visual inspection

- Thickness tester for measuring capsule wall thickness

- Weight balance for measuring capsule weight

- Disintegration and dissolution testers for evaluating capsule release properties

- Moisture analyzer for determining capsule moisture content

5. How do you ensure the accuracy and reliability of your capsule inspections?

To ensure accuracy and reliability in my capsule inspections, I follow several key practices:

- Adhere to established inspection procedures and protocols

- Use calibrated and validated inspection equipment

- Receive regular training and participate in proficiency testing programs

- Maintain a clean and organized inspection environment

- Document inspection findings accurately and thoroughly

6. What is the importance of capsule inspection in the pharmaceutical industry?

Capsule inspection plays a crucial role in the pharmaceutical industry by ensuring:

- Patient safety by identifying defective or contaminated capsules

- Product quality by verifying adherence to specifications and standards

- Regulatory compliance by meeting industry regulations and guidelines

- Brand reputation by maintaining consumer confidence in the safety and efficacy of products

- Cost savings by preventing the distribution of defective capsules and potential recalls

7. How do you prioritize your workload when faced with multiple inspection requests?

When faced with multiple inspection requests, I prioritize my workload based on several factors, including:

- Urgency of the request (e.g., safety concerns)

- Regulatory deadlines

- Product criticality

- Available resources and capacity

- Potential impact on production or distribution

8. Can you describe a situation where you identified a critical defect in a capsule product?

In a recent inspection, I identified a critical defect in a batch of capsules where the disintegration time exceeded the specified limits. This issue could have potentially affected the bioavailability and efficacy of the medication. I immediately escalated the finding to the production team, initiated an investigation, and implemented corrective actions to prevent future occurrences.

9. What are the current industry trends or advancements in capsule inspection technology?

The capsule inspection industry is constantly evolving, with advancements in technology leading to improved efficiency and accuracy. Some notable trends include:

- Automated inspection systems using machine vision and AI

- Non-destructive testing methods for capsule integrity evaluation

- Real-time monitoring and data analysis for process control

- Integration with quality management systems for seamless data management

- Focus on sustainability and eco-friendly inspection practices

10. How do you stay up-to-date with the latest developments in capsule inspection?

To stay up-to-date with the latest developments in capsule inspection, I actively engage in the following:

- Attending industry conferences and workshops

- Reading technical journals and research papers

- Participating in professional organizations and discussion forums

- Seeking knowledge from experienced colleagues and industry experts

- Utilizing online resources and webinars for continuous learning

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Capsule Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Capsule Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Capsule Inspectors are responsible for ensuring the quality and safety of pharmaceutical products by inspecting capsules for defects, contamination, and compliance with specifications

1. Inspect Capsules

Inspect capsules for physical defects, such as cracks, chips, or discoloration

- Use microscopes, magnifying glasses, and other tools to examine capsules

- Identify and remove defective capsules from production lines

2. Ensure Compliance

Inspect capsules for compliance with Good Manufacturing Practices (GMPs) and other regulatory requirements

- Ensure that capsules meet specifications for size, weight, fill volume, and other attributes

- Document inspection results and maintain records

3. Identify and Resolve Defects

Identify the root cause of defects and work with production teams to implement corrective actions

- Analyze inspection data to identify trends and patterns

- Develop and implement quality improvement programs

4. Maintain Equipment

Maintain and calibrate inspection equipment to ensure accurate and reliable results

- Perform preventive maintenance and repairs on inspection equipment

- Follow established procedures for equipment calibration and operation

Interview Tips

To ace your interview for a Capsule Inspector position, consider the following tips:

1. Research the Company and Industry

Learn about the company’s mission, values, and products. Research the pharmaceutical industry to understand the latest trends and regulatory requirements

- Visit the company’s website and social media pages

- Read industry publications and attend conferences

2. Highlight Your Skills and Experience

Emphasize your skills in capsule inspection, quality control, and Good Manufacturing Practices (GMPs). If you have experience in the pharmaceutical industry, highlight your knowledge of regulatory requirements and quality improvement processes

- Use specific examples to demonstrate your skills and experience

- Quantify your accomplishments whenever possible

3. Show Your Attention to Detail

Capsule Inspectors must be highly detail-oriented and able to identify even the smallest defects. In your interview, demonstrate your attention to detail by asking thoughtful questions, actively listening, and providing specific examples of your work

- Ask questions about the company’s quality control processes

- Describe a time when you identified and resolved a difficult defect

4. Prepare for Common Interview Questions

Practice answering common interview questions related to your skills, experience, and motivation. Some common questions for Capsule Inspectors include:

- “Tell me about your experience in capsule inspection.”

- “What are the key qualities of a successful Capsule Inspector?”

- “Why are you interested in working for our company?”

5. Be Confident and Enthusiastic

Confidence and enthusiasm are essential for success in any job interview. Believe in yourself and your abilities, and show the interviewer that you are excited about the opportunity to work as a Capsule Inspector

- Speak clearly and confidently

- Maintain eye contact

- Smile and show enthusiasm

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Capsule Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.