Are you gearing up for a career in Car Greaser? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Car Greaser and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

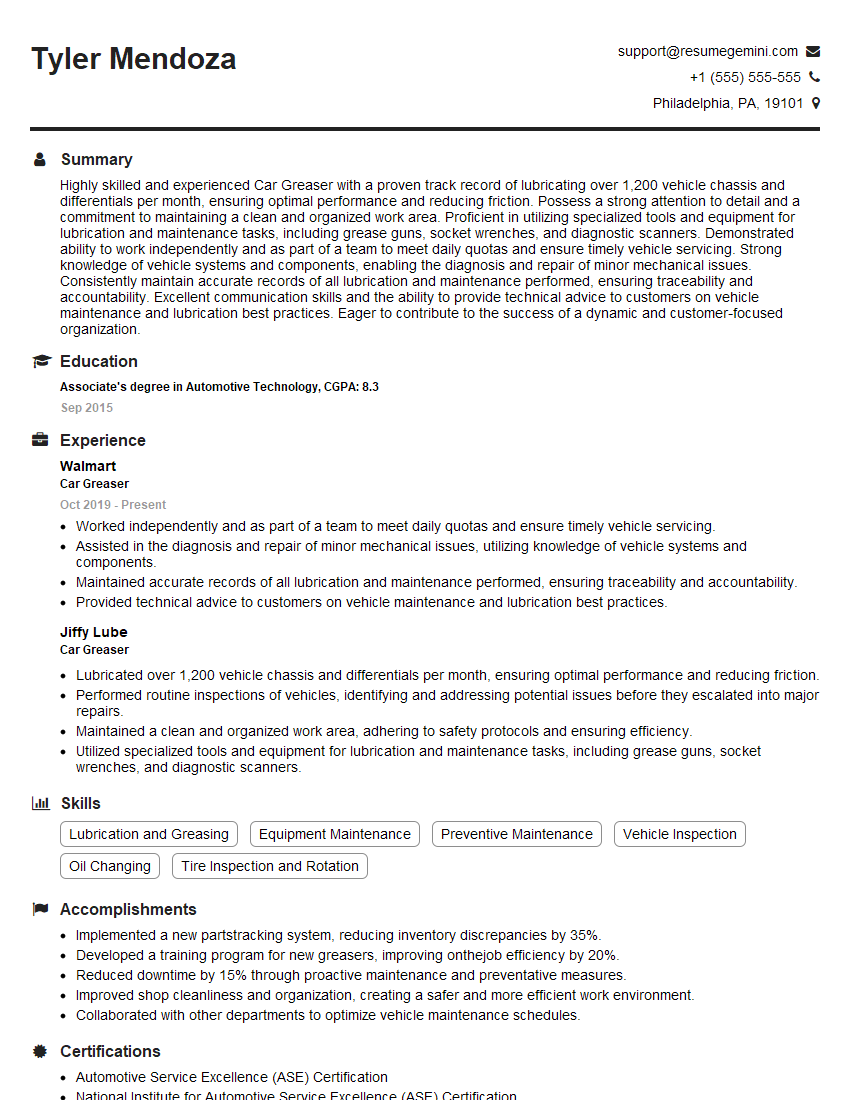

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Car Greaser

1. What are the different types of greases used in automotive applications?

There are several types of greases used in automotive applications, each with specific properties and uses:

- Lithium-based grease: Commonly used for general-purpose automotive applications, such as wheel bearings, chassis components, and door hinges. It offers good water resistance and high-temperature stability.

- Calcium-based grease: Suitable for high-temperature and heavy-load applications, such as fifth wheels, universal joints, and brake calipers. It has excellent water resistance and can withstand extreme pressure.

- Synthetic grease: Formulated with synthetic base oils and thickeners, offering superior performance in extreme temperatures, high loads, and harsh environments. It has excellent water resistance and long-lasting lubrication properties.

- Moly grease: Contains molybdenum disulfide (MoS2) as an additive, providing exceptional wear protection and reducing friction. It is commonly used in high-load and extreme-pressure applications, such as CV joints and wheel bearings.

- Graphite grease: Formulated with graphite powder as an additive, offering excellent dry lubrication properties. It is suitable for applications where oil or grease may not be desirable, such as door locks and window regulators.

2. Describe the correct procedure for lubricating a wheel bearing.

Pre-Lubrication

- Remove the wheel and brake caliper.

- Clean the bearing housing and bearing components thoroughly using a solvent and brush.

- Inspect the bearing for any damage or wear.

Lubrication

- Apply a generous amount of grease to the bearing housing using a grease gun.

- Pack the bearing by hand, ensuring the grease fills the voids between the rollers and races.

- Use a clean cloth or brush to remove excess grease from the bearing and surrounding components.

Post-Lubrication

- Reinstall the bearing and brake caliper.

- Tighten the wheel lug nuts to the specified torque.

- Test the bearing for any noise or vibration.

3. What is the difference between a zerk fitting and a grease nipple?

A zerk fitting and a grease nipple are both lubrication fittings used to inject grease into a component. However, they have different designs and applications:

- Zerk fitting: A zerk fitting is a small, threaded fitting with a ball-check valve. It is designed to be screwed into a component, such as a bearing or chassis component. The ball-check valve opens when a grease gun is connected to the fitting, allowing grease to enter the component.

- Grease nipple: A grease nipple is a nipple-shaped fitting that is pressed or screwed into a component. It is designed to be used with a grease gun that has a pointed nozzle. When the grease gun nozzle is pressed against the nipple, the grease is forced into the component.

In general, zerk fittings are more common in automotive applications, while grease nipples are often used in industrial and agricultural machinery.

4. What safety precautions should be taken when working with high-pressure grease guns?

- Always wear safety glasses and gloves.

- Ensure the grease gun is properly maintained and inspected for any damage or leaks.

- Use the correct lubricant and nozzle for the specific application.

- Never point the grease gun at yourself or others.

- Avoid over-greasing, as it can damage the bearing or component.

- Relieve pressure from the grease gun after each use.

- Dispose of used grease and rags properly.

5. Explain the importance of using the correct grease consistency for a specific application.

- The grease consistency affects the flowability and pumpability of the grease.

- Using too thick a grease can lead to insufficient lubrication and increased friction.

- Using too thin a grease can lead to leakage and loss of lubrication.

- The manufacturer’s recommendations or industry standards should be consulted to determine the correct grease consistency for the application.

6. Describe the different types of grease applicators and their uses.

- Grease guns: Handheld or air-powered devices used to inject grease into bearings, chassis components, and other lubrication points.

- Grease syringes: Small, handheld applicators used to apply grease in precise amounts to small or inaccessible areas.

- Grease brushes: Brushes used to apply grease to larger surfaces, such as gears or chains.

- Grease paddles: Flat, paddle-shaped tools used to apply grease to open gears or bearings.

- Grease couplers: Connectors that allow different types of grease applicators to be attached to grease fittings.

7. What is the significance of using a grease seal to prevent grease leakage?

- Grease seals help prevent the loss of grease from lubricated components.

- They protect the bearing or component from contamination by dirt, water, or other substances.

- Grease seals ensure proper lubrication by retaining the grease within the component.

- Different types of grease seals, such as lip seals, labyrinth seals, and O-rings, are used depending on the specific application and operating conditions.

8. Explain the purpose of a grease fitting on a vehicle and how to use it effectively.

- Grease fittings are small, threaded ports that allow grease to be injected into specific components, such as bearings, steering components, and chassis parts.

- Using a grease gun, grease is forced through the fitting into the component, providing lubrication and reducing friction.

- Regularly greasing fittings helps prevent wear and tear, extends the lifespan of components, and improves the performance of the vehicle.

9. Describe the maintenance schedule for greasing various components on a vehicle.

- The maintenance schedule for greasing components varies depending on the vehicle manufacturer, operating conditions, and driving habits.

- Generally, wheel bearings, universal joints, and steering components require greasing every 5,000-10,000 miles or as recommended in the owner’s manual.

- Chassis components, such as suspension bushings and ball joints, may require greasing every 20,000-30,000 miles or as specified by the manufacturer.

- Regular maintenance and greasing help ensure the proper functioning of the vehicle and extend the lifespan of its components.

10. Identify the potential consequences of neglecting proper greasing of automotive components.

- Neglecting proper greasing can lead to increased friction, accelerated wear and tear, and reduced component lifespan.

- Insufficient lubrication can cause bearings to seize, joints to bind, and chassis components to corrode.

- This can result in premature failure, costly repairs, and reduced vehicle performance.

- Regular greasing helps prevent these issues, ensures smooth operation, and extends the life of the vehicle.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Car Greaser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Car Greaser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Car Greasers or Lubrication Technicians play a vital role in maintaining and caring for vehicles.

1. Lubrication and Maintenance

Their primary responsibility is to lubricate, grease, and maintain various moving parts of vehicles to ensure smooth and efficient operation.

- Inspect and apply grease or oil to bearings, gears, shafts, and other mechanical components

- Monitor oil levels and make adjustments as needed

2. Inspections and Troubleshooting

Car Greasers thoroughly inspect vehicles for maintenance issues and perform necessary repairs or adjustments.

- Identify any potential leaks, damage, or worn-out parts

- Troubleshoot problems and resolve minor issues to improve vehicle performance

3. Vehicle Washing and Detailing

In addition to lubrication and maintenance, some Car Greasers may also be responsible for vehicle washing and detailing.

- Clean exterior and interior surfaces of vehicles

- Bring vehicles to a presentable condition for customers

4. Customer Service

Car Greasers often interact with customers, providing information on maintenance needs and answering any questions they may have.

- Provide excellent customer service by addressing inquiries and resolving concerns

- Build strong relationships with customers

Interview Tips

Preparing thoroughly for a Car Greaser interview can help you showcase your skills and demonstrate your suitability for the role.

1. Research the Industry and Company

Gather information about the automotive industry, different types of vehicles, and the specific company you are applying to. This knowledge will help you understand the job requirements and company culture.

- Visit the company website to learn about their history, values, and services

- Read industry publications and news articles to stay up-to-date

2. Practice Your Technical Skills

Be prepared to talk about your technical abilities and show that you have a good understanding of lubrication, maintenance, and troubleshooting techniques.

- Review lubrication procedures and best practices

- Practice identifying common vehicle problems and troubleshooting

3. Highlight Your Experience and Skills

Emphasize your relevant work experience, demonstrating your practical knowledge and hands-on skills. Showcase your ability to perform tasks such as greasing, inspecting, and diagnosing vehicle issues.

- Provide specific examples of your work history

- Quantify your accomplishments whenever possible

4. Be Enthusiastic and Professional

Show the interviewer that you are passionate about the automotive field and eager to contribute to the company’s success. Maintain a professional demeanor throughout the interview, dressing appropriately and arriving punctually.

- Express your interest in the position and explain why you are a suitable candidate

- Ask thoughtful questions to demonstrate your engagement

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Car Greaser role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.