Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Carbide Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Carbide Operator so you can tailor your answers to impress potential employers.

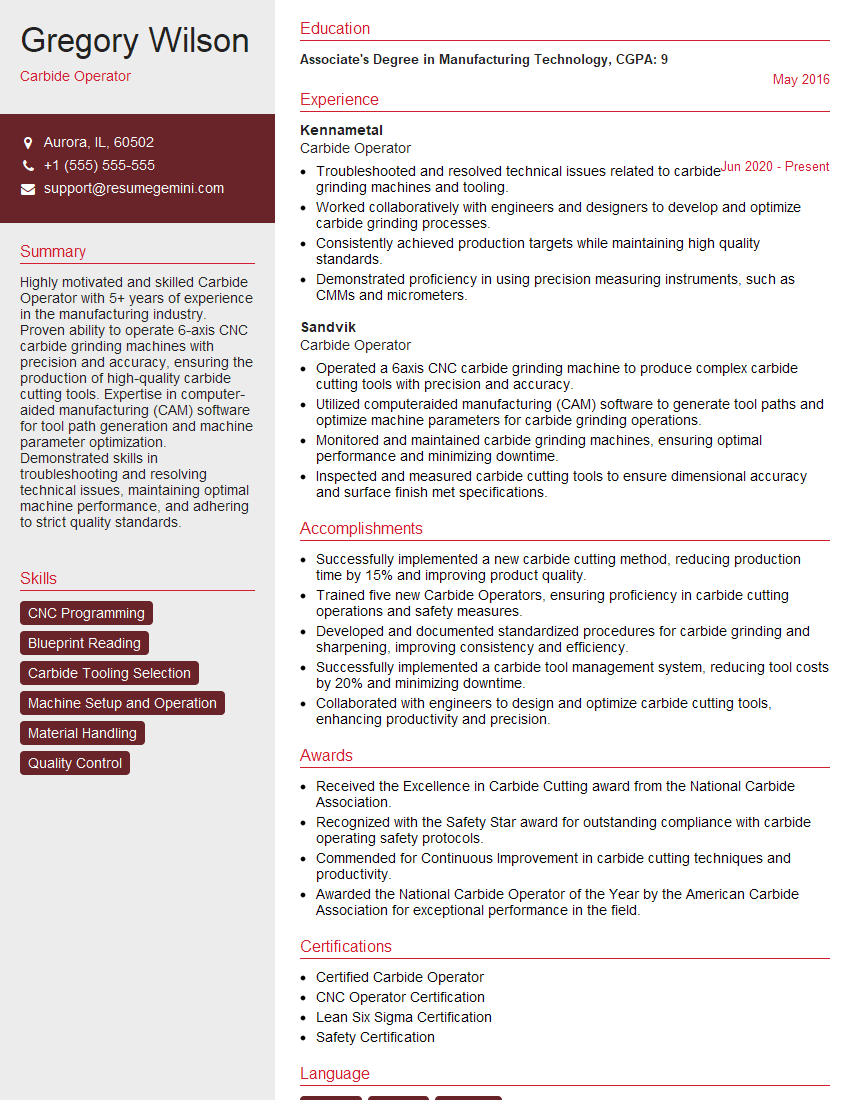

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carbide Operator

1. What are the different types of carbide tools?

- Brazed carbide tools: These tools have carbide tips that are brazed to a steel shank.

- Solid carbide tools: These tools are made entirely of carbide.

- Coated carbide tools: These tools have a coating of titanium nitride or another hard material that increases their wear resistance.

2. What are the advantages of using carbide tools?

- Carbide tools are harder than steel tools, so they can cut faster and last longer.

- Carbide tools are more wear-resistant than steel tools, so they can be used to cut harder materials.

- Carbide tools are more heat-resistant than steel tools, so they can be used to cut materials at higher temperatures.

3. What are the disadvantages of using carbide tools?

- Carbide tools are more expensive than steel tools.

- Carbide tools are more brittle than steel tools, so they can be more easily damaged if they are not used properly.

- Carbide tools can produce a finer finish than steel tools, but they can also be more difficult to sharpen.

4. What are the different types of carbide inserts?

- Positive rake inserts: These inserts have a positive rake angle, which means that the cutting edge is angled up from the cutting direction.

- Negative rake inserts: These inserts have a negative rake angle, which means that the cutting edge is angled down from the cutting direction.

- Neutral rake inserts: These inserts have a neutral rake angle, which means that the cutting edge is perpendicular to the cutting direction.

5. How do you select the right carbide insert for a particular job?

- The type of material being cut.

- The cutting speed and feed rate.

- The desired finish.

6. How do you grind carbide inserts?

- Use a diamond grinding wheel.

- Use a light touch.

- Keep the insert cool.

7. How do you measure the wear on carbide inserts?

- Use a caliper to measure the width of the wear land.

- Use a microscope to measure the depth of the wear land.

8. How do you sharpen carbide inserts?

- Use a diamond grinding wheel.

- Use a light touch.

- Keep the insert cool.

9. What are the safety precautions that must be taken when working with carbide tools?

- Wear eye protection.

- Wear respiratory protection.

- Use sharp tools.

- Keep tools away from children.

10. What are the future trends in carbide tooling?

- Increased use of coated carbide tools.

- Development of new carbide grades.

- Improved grinding techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carbide Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carbide Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Carbide Operators are responsible for operating and maintaining carbide-tipped tools to cut, shape, and finish metal and other materials. They work in a variety of industries, including manufacturing, construction, and automotive.

1. Operating Carbide-Tipped Tools

Carbide Operators use carbide-tipped tools to cut, shape, and finish metal and other materials. They must be able to operate these tools safely and efficiently.

- Selecting the correct carbide-tipped tool for the job

- Setting up the carbide-tipped tool on the machine

- Operating the machine to cut, shape, and finish the material

2. Maintaining Carbide-Tipped Tools

Carbide Operators must also be able to maintain carbide-tipped tools. This includes sharpening the tools, replacing worn parts, and lubricating the tools.

- Sharpening carbide-tipped tools

- Replacing worn parts

- Lubricating carbide-tipped tools

3. Quality Control

Carbide Operators are also responsible for quality control. They must be able to inspect the finished product to ensure that it meets the required specifications.

- Inspecting the finished product

- Identifying and correcting defects

4. Safety

Carbide Operators must also be able to work safely. They must be aware of the hazards associated with their work and they must take precautions to avoid accidents.

- Wearing proper safety gear

- Following safety procedures

- Maintaining a clean and organized work area

Interview Tips

To ace an interview for a Carbide Operator position, it is important to be prepared. Here are a few tips:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work at the company

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked. It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Tell me about yourself

- Why are you interested in this position?

- What are your strengths and weaknesses?

3. Be prepared to talk about your experience

The interviewer will want to know about your experience as a Carbide Operator. Be prepared to talk about your skills and accomplishments.

- Describe your experience operating carbide-tipped tools

- Discuss your experience maintaining carbide-tipped tools

- Highlight your quality control experience

4. Be prepared to answer questions about safety

The interviewer will want to know about your safety knowledge and experience. Be prepared to answer questions about your safety practices.

- Describe your safety training

- Discuss your experience following safety procedures

- Highlight your commitment to safety

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Carbide Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Carbide Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.