Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Carbon and Graphite Brush Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Carbon and Graphite Brush Machine Operator so you can tailor your answers to impress potential employers.

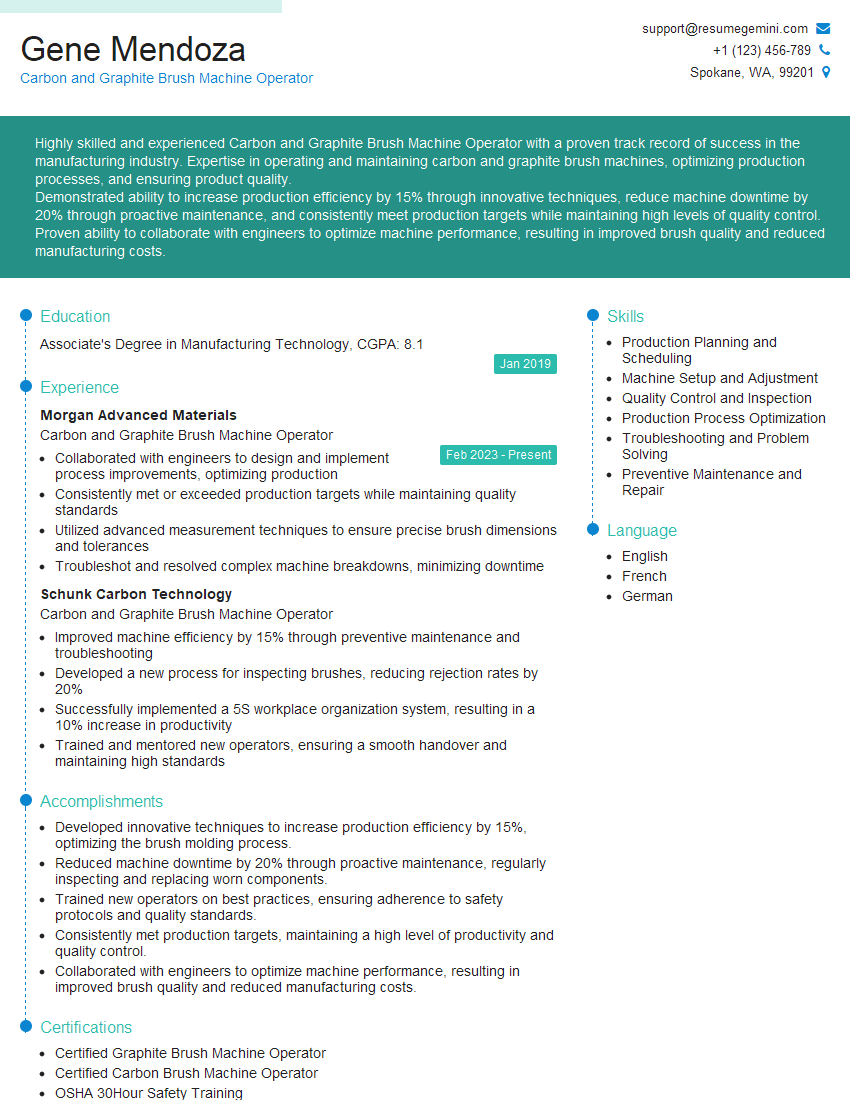

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carbon and Graphite Brush Machine Operator

1. What are the key responsibilities of a Carbon and Graphite Brush Machine Operator?

The key responsibilities of a Carbon and Graphite Brush Machine Operator include:

- Operating and maintaining carbon and graphite brush making machinery

- Setting up and adjusting machines to produce brushes to specified dimensions and tolerances

- Inspecting brushes for defects and ensuring they meet quality standards

- Troubleshooting and resolving machine malfunctions

- Maintaining a clean and safe work area

2. What are the different types of brush machines used in the production of carbon and graphite brushes?

The different types of brush machines used in the production of carbon and graphite brushes include:

- Extrusion machines

- Compression molding machines

- Injection molding machines

- Sintering furnaces

- Grinding and finishing machines

3. What are the factors that affect the quality of carbon and graphite brushes?

The factors that affect the quality of carbon and graphite brushes include:

- The type and quality of raw materials used

- The manufacturing process used

- The heat treatment process

- The finishing process

- The storage conditions

4. What are the different applications of carbon and graphite brushes?

Carbon and graphite brushes are used in a variety of applications, including:

- Electrical motors and generators

- Automotive starters and alternators

- Power tools

- Household appliances

- Industrial machinery

5. What are the safety precautions that must be taken when working with carbon and graphite?

The safety precautions that must be taken when working with carbon and graphite include:

- Wearing appropriate personal protective equipment, such as gloves, safety glasses, and a dust mask

- Working in a well-ventilated area

- Avoiding contact with skin and eyes

- Storing carbon and graphite in a safe and dry place

- Properly disposing of waste materials

6. What is the difference between carbon brushes and graphite brushes?

Carbon brushes are made from pure carbon, while graphite brushes are made from a mixture of carbon and graphite. Graphite brushes are generally more expensive than carbon brushes, but they offer a number of advantages, including:

- Higher current carrying capacity

- Lower contact resistance

- Longer life

- Reduced sparking

7. What are the different grades of carbon and graphite brushes available?

Carbon and graphite brushes are available in a variety of grades, each with its own unique properties. The most common grades include:

- Soft grades: These brushes are made from a mixture of carbon and graphite and are used in applications where low friction and wear resistance are important.

- Medium grades: These brushes are made from a higher percentage of graphite than soft grades and offer a good balance of wear resistance and current carrying capacity.

- Hard grades: These brushes are made from a high percentage of carbon and are used in applications where high wear resistance is important.

8. How do you inspect carbon and graphite brushes for defects?

Carbon and graphite brushes should be inspected for defects before they are installed in equipment. The most common defects include:

- Cracks

- Chips

- Foreign objects

- неправильный размер

- Incorrect shape

9. How do you troubleshoot a carbon and graphite brush machine?

There are a number of things that can go wrong with a carbon and graphite brush machine. Some of the most common problems include:

- The machine is not producing brushes to the correct dimensions or tolerances

- The brushes are defective

- The machine is making excessive noise

- The machine is not running smoothly

- The machine is not working at all

10. What is your experience with carbon and graphite brush machines?

I have been working with carbon and graphite brush machines for the past 5 years. In my previous role, I was responsible for operating and maintaining a variety of brush machines. I have a thorough understanding of the manufacturing process and can troubleshoot and resolve most problems that arise. I am also familiar with the different grades of carbon and graphite brushes and can recommend the best brush for any given application.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carbon and Graphite Brush Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carbon and Graphite Brush Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Carbon and Graphite Brush Machine Operators play a crucial role in the production process at manufacturing plants. Their primary responsibility involves operating machines that produce carbon and graphite brushes, essential components used in various industries such as electrical, automotive, and renewable energy.

1. Machine Operation and Maintenance

Operators are responsible for setting up, operating, and maintaining carbon and graphite brush machines. They ensure that machines run efficiently by performing regular maintenance checks, calibrations, and adjustments.

- Set up and operate machines to produce carbon and graphite brushes.

- Monitor and adjust machine settings to optimize production.

- Perform preventive maintenance and troubleshooting to keep machines running smoothly.

2. Quality Assurance

Operators are responsible for ensuring that the brushes produced meet quality specifications. They conduct regular inspections and tests to check for defects and adherence to standards.

- Inspect and test brushes to ensure they meet quality standards.

- Identify and correct defects in brushes.

- Maintain records of inspection and test results.

3. Production Planning and Scheduling

Operators work closely with production planners to schedule production and ensure that orders are fulfilled on time. They monitor inventory levels and adjust production schedules accordingly.

- Plan and schedule production to meet customer orders.

- Monitor inventory levels and adjust production schedules as needed.

- Coordinate with production planners to ensure smooth operation.

4. Safety and Compliance

Operators are responsible for maintaining a safe and compliant work environment. They follow established safety protocols, wear appropriate safety gear, and report any potential hazards.

- Follow established safety protocols and wear appropriate safety gear.

- Identify and report potential hazards.

- Maintain a clean and organized work area.

Interview Tips

To ace the interview for a Carbon and Graphite Brush Machine Operator position, candidates should prepare thoroughly and highlight their relevant skills and experience.

1. Research the Company and Role

Before the interview, candidates should thoroughly research the company and the specific role they are applying for. This will help them understand the company’s mission, values, and production processes, enabling them to tailor their answers accordingly.

- Visit the company’s website and read about their history, products, and culture.

- Review the job description carefully and identify the key requirements.

- Prepare questions to ask the interviewer about the company and the role.

2. Highlight Relevant Skills and Experience

Candidates should emphasize their skills and experience in operating carbon and graphite brush machines, as well as their knowledge of quality control procedures. They should also highlight any safety training or certifications they possess.

- Quantify your experience by providing specific examples of your accomplishments.

- Use action verbs to describe your responsibilities and achievements.

- Tailor your answers to the specific requirements of the job description.

3. Demonstrate Problem-Solving Abilities

Operators often encounter problems with machines or production processes. Candidates should demonstrate their ability to identify, analyze, and solve problems effectively.

- Provide examples of how you have solved problems in previous roles.

- Explain your problem-solving process and how you ensure solutions are effective.

- Highlight your ability to remain calm and focused under pressure.

4. Emphasize Safety and Compliance

Safety is paramount in any manufacturing environment. Candidates should emphasize their commitment to safety by highlighting their knowledge of safety protocols and their experience in maintaining a safe work environment.

- Explain how you prioritize safety in your daily work.

- Describe your experience in following safety procedures and reporting hazards.

- Discuss any safety training or certifications you have obtained.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Carbon and Graphite Brush Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!