Feeling lost in a sea of interview questions? Landed that dream interview for Carbon Coater Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Carbon Coater Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

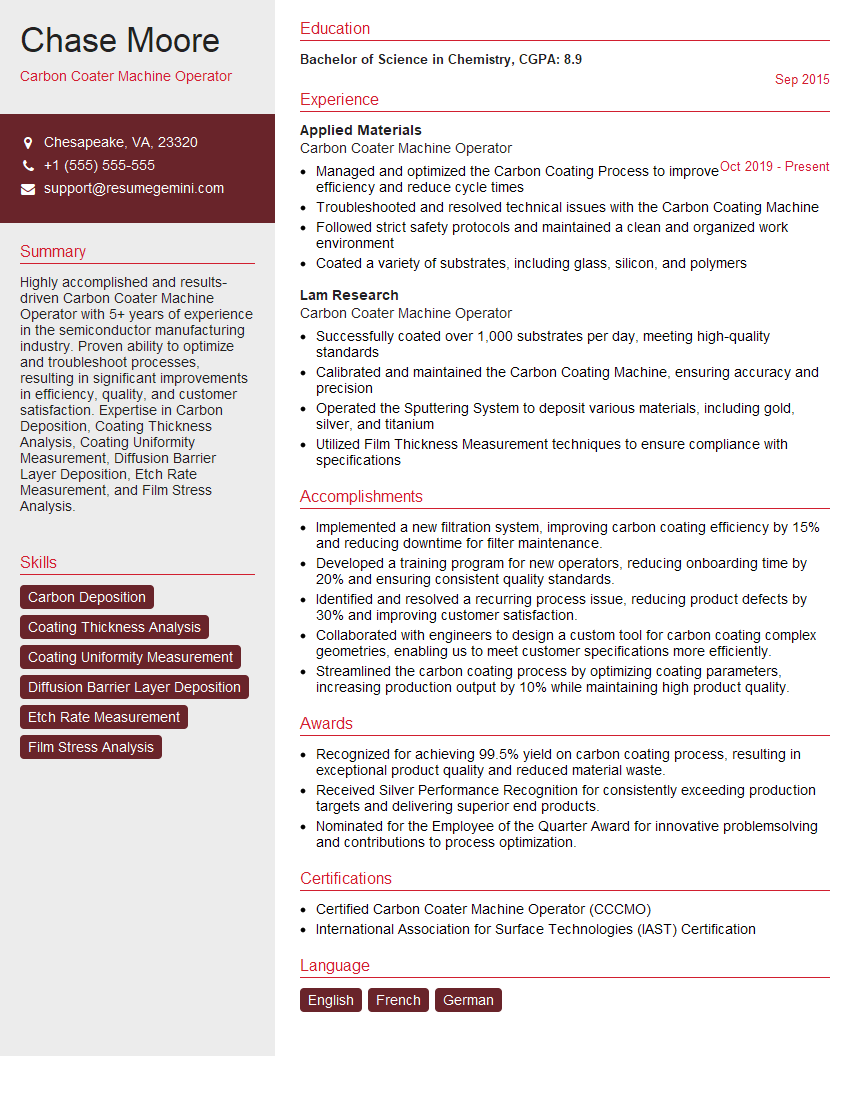

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carbon Coater Machine Operator

1. Explain the key steps involved in the carbon coating process?

The key steps involved in the carbon coating process are as follows:

- Substrate preparation: The surface of the substrate is cleaned and prepared to ensure that it is free of contaminants.

- Coating deposition: A thin layer of carbon is deposited onto the substrate using a variety of techniques, including physical vapor deposition (PVD), chemical vapor deposition (CVD), and plasma-enhanced chemical vapor deposition (PECVD).

- Coating characterization: The thickness, structure, and properties of the carbon coating are characterized using various techniques, such as X-ray diffraction (XRD), scanning electron microscopy (SEM), and atomic force microscopy (AFM).

2. What are the different types of carbon coatings?

Physical vapor deposition (PVD) coatings

- Sputtering

- Arc evaporation

- Electron beam evaporation

Chemical vapor deposition (CVD) coatings

- Thermal CVD

- Plasma-enhanced CVD (PECVD)

- Low-pressure CVD (LPCVD)

3. What are the advantages and disadvantages of using carbon coatings?

- Advantages: Carbon coatings are hard, durable, and wear-resistant. They also have a low coefficient of friction and are resistant to corrosion and oxidation.

- Disadvantages: Carbon coatings can be brittle and may not adhere well to all substrates.

4. What are the applications of carbon coatings?

- Cutting tools

- Medical devices

- Aerospace components

- Automotive parts

- Electronics

5. What are the challenges associated with carbon coating?

- Coating thickness control: It is important to control the thickness of the carbon coating to ensure that it meets the desired specifications.

- Coating adhesion: The carbon coating must adhere well to the substrate to ensure that it does not peel or flake off.

- Coating uniformity: The carbon coating must be uniform across the entire surface of the substrate.

6. What are the safety precautions that should be taken when working with carbon coatings?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a respirator.

- Handle carbon coatings with care to avoid contact with skin or eyes.

- Do not ingest or inhale carbon coatings.

- Dispose of carbon coatings properly according to local regulations.

7. What are the quality control procedures that should be followed when manufacturing carbon coatings?

- Inspect the substrate to ensure that it is clean and free of contaminants.

- Monitor the coating process to ensure that the coating thickness, adhesion, and uniformity meet the desired specifications.

- Test the coated substrate to ensure that it meets the required performance criteria.

8. What are the future trends in carbon coating technology?

- Development of new carbon coating materials: New carbon coating materials are being developed to meet the demands of emerging applications.

- Improvement of coating processes: Coating processes are being improved to increase the efficiency and quality of carbon coatings.

- Exploration of new applications: Carbon coatings are being explored for use in a variety of new applications, such as energy storage and biomedical devices.

9. How can I improve my skills as a Carbon Coater Machine Operator?

- Attend training courses and workshops on carbon coating.

- Read technical articles and books on carbon coating.

- Experiment with different carbon coating parameters to improve the quality of your coatings.

- Network with other Carbon Coater Machine Operators to share knowledge and best practices.

10. What are your career goals as a Carbon Coater Machine Operator?

- I want to become a highly skilled Carbon Coater Machine Operator.

- I want to learn as much as I can about carbon coating technology.

- I want to use my skills to help my company produce high-quality carbon coatings.

- I want to eventually become a supervisor or manager in the carbon coating industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carbon Coater Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carbon Coater Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Carbon Coater Machine Operators are responsible for the safe and efficient operation of carbon coating machines, which are used to deposit a thin layer of carbon onto a variety of materials. They must have a strong understanding of the machine’s operation and maintenance procedures, as well as the properties of different carbon materials. Key responsibilities include:

1. Machine Operation

Safely and efficiently operate the carbon coating machine, including loading and unloading materials, setting up process parameters, and monitoring the machine’s performance.

- Load and unload materials into the machine.

- Set up process parameters, such as temperature, pressure, and deposition rate.

- Monitor the machine’s performance and make adjustments as needed.

- Troubleshoot and resolve any problems that arise with the machine.

2. Material Handling

Handle carbon materials safely and properly, including loading and unloading materials, storing materials, and disposing of waste.

- Load and unload carbon materials from the machine.

- Store carbon materials in a safe and dry place.

- Dispose of waste carbon materials in accordance with environmental regulations.

3. Quality Control

Inspect coated materials to ensure that they meet the required specifications, including thickness, uniformity, and adhesion. Perform quality control tests on coated materials to ensure that they meet the required specifications.

- Inspect coated materials for defects.

- Perform quality control tests on coated materials.

- Maintain records of quality control data.

4. Maintenance and Repair

Perform basic maintenance and repairs on the carbon coating machine, including cleaning, lubrication, and adjustment. Perform basic maintenance and repairs on the carbon coating machine, including cleaning, lubrication, and adjustment.

- Clean the carbon coating machine.

- Lubricate the carbon coating machine.

- Adjust the carbon coating machine.

- Replace worn or damaged parts.

Interview Tips

To ace your interview for a Carbon Coater Machine Operator position, it’s important to prepare thoroughly and highlight your relevant skills and experience. Here are some tips to help you succeed:

1. Research the Company and the Position

Take the time to learn about the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture, values, and goals, and tailor your answers accordingly.

- Visit the company’s website and social media pages.

- Read industry news and articles.

- Talk to people in your network who work in the industry.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Highlight Your Relevant Skills and Experience

Make sure to highlight your relevant skills and experience in your resume and cover letter, and be prepared to discuss them in detail during your interview. This includes your technical skills, such as your knowledge of carbon coating machines and materials, as well as your soft skills, such as your attention to detail and problem-solving abilities.

- Quantify your accomplishments whenever possible.

- Use specific examples to illustrate your skills and experience.

- Be enthusiastic and passionate about your work.

4. Ask Questions

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role.

- Ask about the company’s culture and values.

- Ask about the company’s future plans.

- Ask about the specific responsibilities of the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Carbon Coater Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!