Feeling lost in a sea of interview questions? Landed that dream interview for Carbon Coating Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Carbon Coating Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

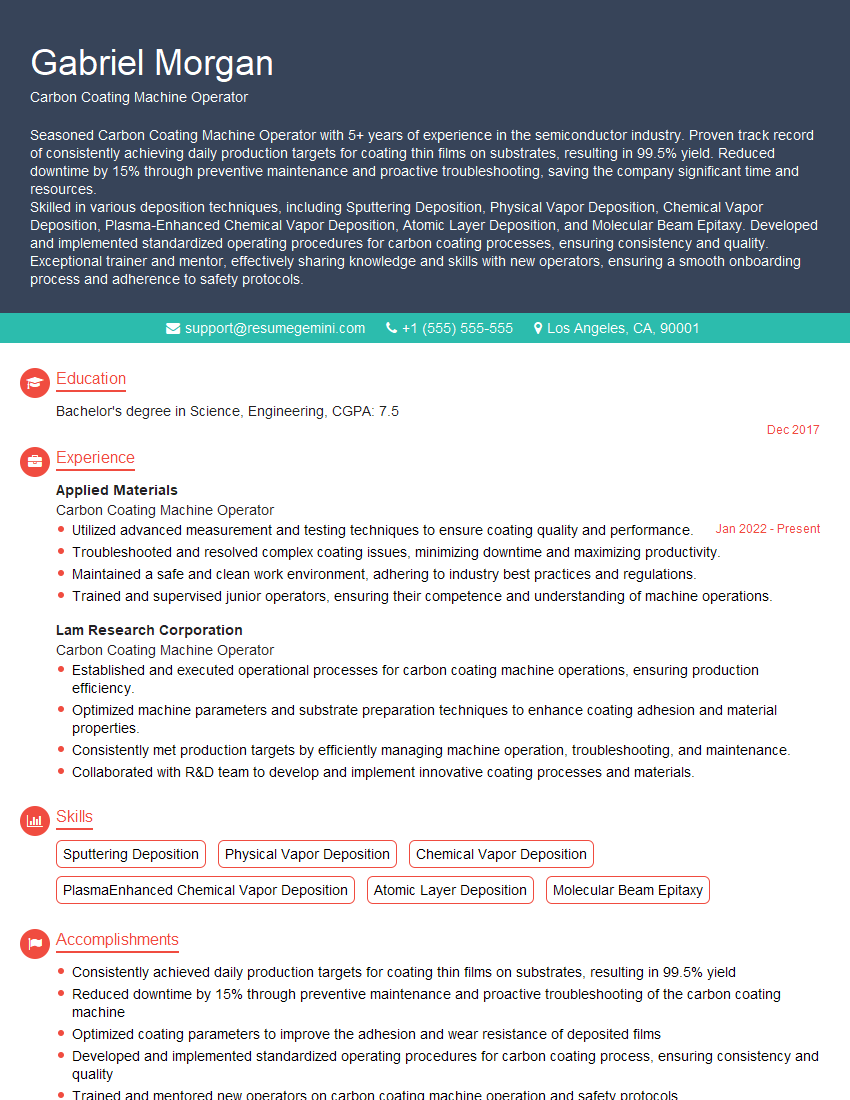

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carbon Coating Machine Operator

1. Describe the different types of carbon coatings and their applications.

There are various types of carbon coatings, each with specific properties and applications. Here are a few common types:

- Diamond-like carbon (DLC): DLC coatings are known for their extreme hardness, wear resistance, and low friction. They are often used in cutting tools, bearings, and other components that require high durability.

- Tetrahedral amorphous carbon (ta-C): Ta-C coatings provide a combination of high hardness and good electrical conductivity. They are commonly used in electronic devices, such as semiconductors and solar cells, and in optical components.

- Graphite-like carbon (GLC): GLC coatings have a layered structure similar to graphite. They exhibit high electrical and thermal conductivity and are often used in applications such as heat sinks, electrodes, and battery materials.

- Carbon nanotubes (CNTs): CNT coatings consist of cylindrical carbon molecules. They have exceptional mechanical strength, thermal conductivity, and electrical properties. CNT coatings are used in various applications, including composites, sensors, and electronic devices.

2. What are the key parameters that affect the quality of carbon coatings?

- Substrate preparation: The surface preparation of the substrate prior to coating significantly impacts the coating’s adhesion and performance.

- Coating material: The choice of carbon material (e.g., graphite, diamond, CNTs) and its properties influence the coating’s characteristics.

- Coating technique: The method used to apply the coating (e.g., chemical vapor deposition, physical vapor deposition) affects the coating’s structure and properties.

- Process parameters: Factors such as temperature, pressure, and deposition rate during the coating process influence the coating’s properties.

- Post-treatment: Additional processes like annealing or etching can enhance the coating’s performance and stability.

3. Explain the different methods used for carbon coating and their respective advantages and disadvantages.

There are several methods for carbon coating, each with its unique advantages and disadvantages:

Chemical vapor deposition (CVD)

- Advantages: CVD produces conformal coatings with high purity and good adhesion. It allows for precise control over coating thickness and composition.

- Disadvantages: CVD can be a slow process and requires specialized equipment and high temperatures.

Physical vapor deposition (PVD)

- Advantages: PVD is a relatively fast process and can produce dense, hard coatings. It is suitable for coating large surfaces.

- Disadvantages: PVD coatings may have lower adhesion compared to CVD coatings, and the coating thickness can be limited.

Plasma-enhanced chemical vapor deposition (PECVD)

- Advantages: PECVD combines CVD and plasma techniques, providing improved coating adhesion and conformal coverage. It can produce coatings at lower temperatures.

- Disadvantages: PECVD can be more complex and expensive than other methods.

4. How do you maintain and troubleshoot a carbon coating machine?

- Regular maintenance: Follow manufacturer’s guidelines for scheduled maintenance, including cleaning the chamber, replacing filters, and calibrating the equipment.

- Troubleshooting: Identify potential issues based on symptoms, such as poor coating quality, equipment malfunctions, or safety concerns. Use diagnostic tools and consult manuals to resolve problems.

- Preventive measures: Implement measures to prevent issues, such as using high-quality materials, maintaining proper operating conditions, and training operators.

5. Describe your experience in operating carbon coating equipment and any specific challenges you encountered.

In my previous role, I was responsible for operating a carbon coating machine used for producing DLC coatings on cutting tools. I ensured proper machine setup, monitored process parameters, and maintained the equipment. One challenge I faced was optimizing coating parameters to achieve a balance between wear resistance and friction reduction. Through experimentation and collaboration with engineers, I successfully adjusted the process to meet the desired specifications.

6. Explain how you ensure the quality and consistency of carbon coatings.

- Control process parameters: Monitor and control critical process parameters such as temperature, pressure, and deposition rate to achieve consistent coating properties.

- Quality control testing: Perform quality control tests, such as thickness measurements, adhesion tests, and surface characterization, to verify coating specifications.

- Regular calibration and maintenance: Regularly calibrate equipment and perform maintenance to maintain machine accuracy and reliability.

7. How do you handle and store carbon coating materials safely?

- Follow safety protocols: Adhere to established safety protocols for handling and storing carbon coating materials, including wearing appropriate protective gear.

- Proper storage: Store materials in designated, dry, and well-ventilated areas to prevent contamination and ensure their stability.

- Waste disposal: Dispose of used or expired materials according to environmental regulations and safety guidelines.

8. Describe your understanding of the environmental impact of carbon coating processes.

Carbon coating processes can have environmental implications, primarily due to the use of hazardous chemicals and the generation of waste materials. It is important to implement measures to minimize the environmental impact, such as:

- Using eco-friendly materials: Exploring and adopting alternative, non-hazardous coating materials to reduce the environmental footprint.

- Waste management: Implementing proper waste management practices, including recycling and safe disposal, to reduce environmental contamination.

- Energy efficiency: Optimizing coating processes to improve energy efficiency and reduce greenhouse gas emissions.

9. How do you stay updated with the latest advancements in carbon coating technology?

- Attend industry events: Participate in conferences, workshops, and trade shows to learn about new technologies and research findings.

- Read technical literature: Stay informed by reading scientific journals, technical articles, and industry publications related to carbon coating.

- Engage with experts: Network with professionals in the field, including researchers, engineers, and suppliers, to exchange knowledge and stay abreast of industry trends.

10. What are your career goals and how does this position align with them?

My career goal is to contribute to the advancement of carbon coating technology and its applications. I believe this position offers a valuable opportunity for me to gain hands-on experience in operating and maintaining carbon coating equipment, while also contributing to the development and optimization of coating processes. I am eager to learn from experienced professionals and apply my skills to drive innovation in this field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carbon Coating Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carbon Coating Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Carbon Coating Machine Operator is responsible for operating and maintaining carbon coating machines, ensuring that they produce high-quality carbon coatings on various substrates. The key job responsibilities include:1. Machine Operation

Operate carbon coating machines, following established procedures and safety protocols.

- Load substrates into the machine and ensure proper positioning and alignment.

- Set and adjust machine parameters, such as temperature, pressure, and coating thickness.

- Monitor machine performance and make necessary adjustments to optimize the coating process.

2. Quality Control

Inspect coated substrates to ensure they meet quality specifications.

- Perform visual inspections, dimensional measurements, and surface roughness tests.

- Identify and correct any defects or irregularities in the coating.

- Maintain accurate records of coating parameters and inspection results.

3. Maintenance and Repair

Conduct routine maintenance and repairs on carbon coating machines.

- Clean and lubricate machine components.

- Replace worn or damaged parts.

- Troubleshoot and resolve machine malfunctions.

4. Process Optimization

Work with engineers and production personnel to optimize the carbon coating process.

- Identify areas for improvement in coating quality, efficiency, and cost-effectiveness.

- Suggest and implement process modifications to enhance productivity and reduce waste.

- Stay abreast of emerging coating technologies and best practices.

Interview Tips

To ace the interview for a Carbon Coating Machine Operator position, here are some preparation tips:1. Research the Company and Position

Gather information about the company’s industry, products, and culture.

- Visit the company’s website, LinkedIn page, and Glassdoor reviews.

- Learn about the specific job responsibilities and qualifications required.

2. Highlight Your Experience and Skills

Emphasize your experience in operating and maintaining carbon coating machines.

- Quantify your accomplishments using specific metrics and examples.

- Showcase your knowledge of coating processes, quality control techniques, and maintenance protocols.

3. Practice Common Interview Questions

Prepare for behavioral and technical questions that may be asked in the interview.

- Develop answers to questions related to your experience, skills, and motivation.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses.

4. Demonstrate Your Safety Awareness

Carbon coating machines involve potential hazards.

- Explain your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Provide examples of how you have implemented safety measures in previous roles.

5. Show Enthusiasm and Interest

Convey your passion for the field of carbon coating.

- Describe your interest in the industry and the role of carbon coating in various applications.

- Ask thoughtful questions during the interview to demonstrate your curiosity and engagement.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Carbon Coating Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Carbon Coating Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.