Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Carbon Furnace Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

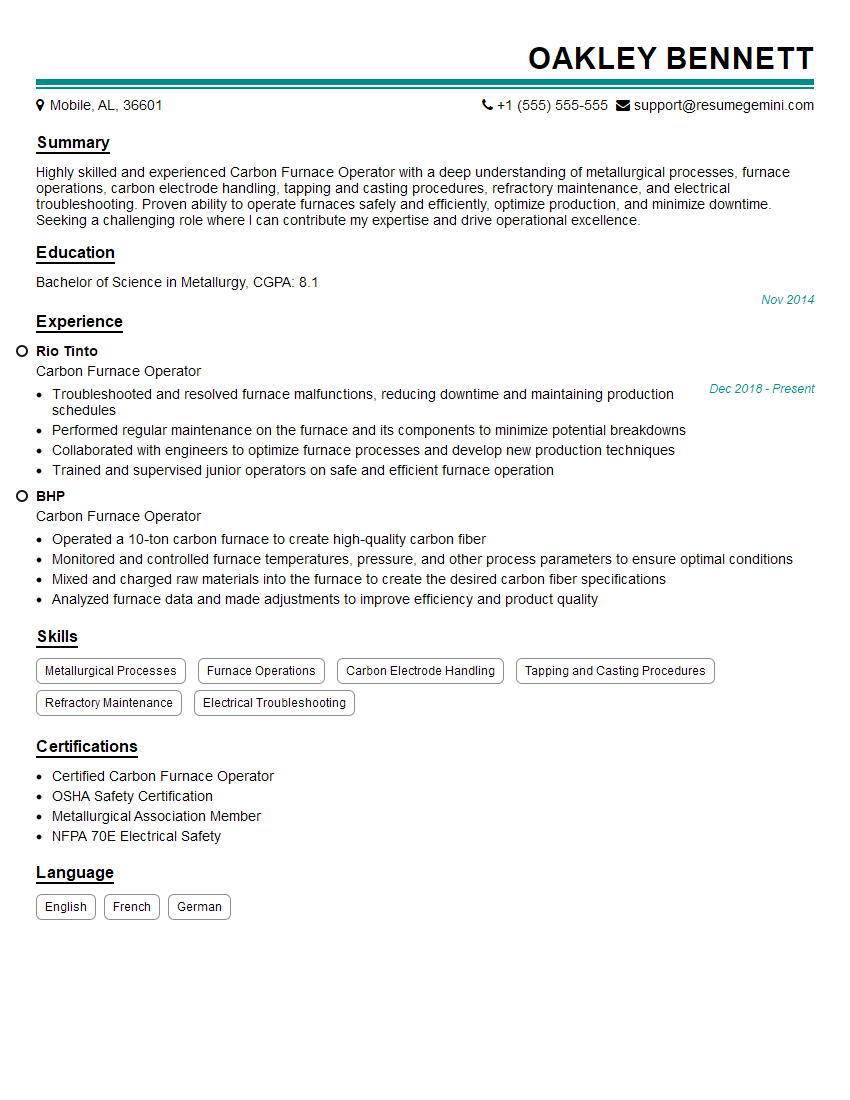

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carbon Furnace Operator

1. Explain the process of carbonization in a carbon furnace?

Carbonization is the process of converting organic materials into carbon. In a carbon furnace, this is done by heating the material in an oxygen-free environment so that the volatile components are driven off. The remaining carbon is then further heated to produce a pure, dense carbon product.

- Materials are loaded into the furnace chamber

- Temperature is raised to 1,000-1,400 °C to drive off liquid and gas

- Volatile components are collected and condensed for reuse

- Remaining solid is further baked to form final carbon product

2. What are the key operating parameters for a carbon furnace?

- Temperature control: The temperature within the furnace is critical to the carbonization process, as it affects the rate of reaction and the quality of the final product.

- Oxygen content: The oxygen content within the furnace must be kept low to prevent combustion of the carbon and maintain the desired reaction conditions.

- Feed rate: The rate at which material is fed into the furnace must be controlled to ensure efficient operation and prevent overloading.

- Residence time: The amount of time that material remains in the furnace is a key factor in determining the degree of carbonization.

3. What are the different types of carbon furnaces?

- Batch furnaces: These furnaces are loaded with a batch of material that is processed at one time. Batch furnaces are typically used for small-scale production or for specialized applications.

- Continuous furnaces: These furnaces are designed for continuous operation, with material being fed into and removed from the furnace on a continuous basis. Continuous furnaces are typically used for large-scale production.

- Rotary kilns: These furnaces are long, cylindrical furnaces that rotate as they heat the material. Rotary kilns are often used for processing large quantities of material.

4. What are the safety considerations for operating a carbon furnace?

- Carbon monoxide poisoning: Carbon monoxide is a byproduct of the carbonization process, and it can be dangerous if inhaled. Proper ventilation is essential to prevent carbon monoxide buildup in the workplace.

- Fire hazard: Carbon furnaces operate at high temperatures, and there is a risk of fire if the furnace is not properly maintained. Measures such as fire extinguishers and sprinklers should be in place to prevent and suppress fires.

- Electrical hazards: Carbon furnaces use high-voltage electricity, and there is a risk of electrical shock if the equipment is not properly grounded and maintained.

- Exposure to molten carbon: Molten carbon can cause severe burns. Proper protective clothing and equipment should be worn when working near molten carbon.

5. What are the maintenance requirements for a carbon furnace?

- Regular cleaning: Carbon furnaces should be cleaned regularly to remove any buildup of carbon or other materials that can affect performance.

- Mechanical inspections: The mechanical components of the furnace, such as the bearings and drive system, should be inspected regularly to ensure they are in good working condition.

- Electrical inspections: The electrical components of the furnace, such as the wiring and controls, should be inspected regularly to ensure they are safe and functioning properly.

- Refractory maintenance: The refractory lining of the furnace should be inspected regularly and replaced as needed to maintain the integrity of the furnace and prevent heat loss.

6. What are the troubleshooting tips for a carbon furnace?

- Low product yield: This can be caused by factors such as insufficient temperature, insufficient residence time, or poor feedstock quality.

- High energy consumption: This can be caused by factors such as poor insulation, excessive heat loss, or inefficient combustion.

- Equipment failures: These can be caused by factors such as mechanical wear, electrical faults, or refractory failure.

- Environmental issues: These can be caused by factors such as carbon monoxide emissions, dust emissions, or wastewater discharge.

7. What are the latest advancements in carbon furnace technology?

- Energy-efficient furnaces: These furnaces incorporate advanced insulation and heat recovery systems to reduce energy consumption.

- Intelligent control systems: These systems use sensors and automation to optimize furnace performance and reduce operator intervention.

- Advanced refractory materials: These materials provide improved thermal insulation and corrosion resistance, leading to longer furnace life and reduced maintenance costs.

- Environmental control systems: These systems minimize emissions and wastewater discharge to meet environmental regulations.

8. What are the future trends in the carbon furnace industry?

- Increasing demand for carbon products: Growing applications in industries such as energy storage, electronics, and transportation are driving the demand for carbon products.

- Focus on sustainability: Environmental regulations and the need for energy efficiency are driving the development of more sustainable carbon furnace technologies.

- Automation and digitization: Advanced control systems and data analytics are being adopted to optimize furnace performance and reduce operating costs.

- Integration with renewable energy: Carbon furnaces are being integrated with renewable energy sources, such as solar and wind power, to reduce carbon emissions.

9. What are the challenges faced by the carbon furnace industry?

- Volatile raw material prices: The cost of raw materials, such as coal and petroleum coke, can fluctuate significantly, impacting production costs.

- Environmental regulations: Stringent environmental regulations can increase the cost of operating carbon furnaces and require costly upgrades to meet emission standards.

- Competition from alternative technologies: Other technologies, such as biomass gasification and solar energy, are emerging as alternatives to carbon furnaces, creating competition for market share.

- Lack of skilled labor: The carbon furnace industry requires specialized skills and knowledge, and there is a shortage of qualified workers in some regions.

10. What are the opportunities for growth in the carbon furnace industry?

- Growing demand for carbon products: The increasing demand for carbon products in various industries presents opportunities for growth.

- Technological advancements: Innovations in carbon furnace technology can improve efficiency, reduce costs, and enhance environmental performance.

- Emerging markets: Expanding into new markets, particularly in developing countries, can provide opportunities for growth.

- Value-added products: Offering specialized carbon products or services, such as custom-engineered carbon solutions, can create additional revenue streams.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carbon Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carbon Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Carbon Furnace Operators play a crucial role in the production of steel and other high-carbon materials, ensuring that the raw materials are transformed into the desired end product. Their primary responsibilities include:

1. Furnace Operation

Monitoring and operating carbon furnaces to produce high-carbon products, such as steel, pig iron, and ferroalloys.

2. Raw Material Preparation

Preparing and blending raw materials, including coke, iron ore, and fluxes, to create the appropriate composition for the furnace charge.

3. Furnace Charge Management

Loading and charging the furnace with the prepared raw materials, ensuring the correct proportions and sequencing.

4. Temperature and Gas Control

Monitoring and adjusting furnace temperature and gas flow to optimize the chemical reactions within the furnace.

5. Slag Management

Controlling the formation and removal of slag, which is a byproduct of the furnace process, to prevent contamination of the final product.

6. Quality Control

Sampling and testing the final product to ensure it meets the desired specifications and quality standards.

7. Maintenance and Troubleshooting

Performing routine maintenance and troubleshooting procedures on the furnace and associated equipment to maintain optimal performance.

Interview Tips

Preparing for an interview as a Carbon Furnace Operator requires careful planning and attention to detail. Here are some tips to help you ace the interview:

1. Research the Company and Role

Familiarize yourself with the company’s history, products, and mission, as well as the specific requirements of the Carbon Furnace Operator role. This demonstrates your interest and understanding of the organization.

2. Practice Answering Common Interview Questions

Anticipate and prepare for common interview questions related to your technical skills, experience in furnace operation, and problem-solving abilities. Practice your responses to provide clear and concise answers.

3. Highlight Your Technical Expertise

Emphasize your knowledge and understanding of the carbon furnace process, including the principles of metallurgy, thermodynamics, and combustion. Showcase your ability to analyze data, interpret results, and make informed decisions based on technical information.

4. Demonstrate Your Problem-Solving Abilities

Provide examples of situations where you have successfully identified and resolved problems related to furnace operation or equipment maintenance. Describe your approach to troubleshooting, analyzing data, and implementing effective solutions.

5. Showcase Your Safety and Environmental Awareness

Carbon furnace operation involves handling hazardous materials and working in potentially dangerous environments. Highlight your commitment to safety and environmental protection by describing your knowledge of safety regulations, hazard identification, and emergency response procedures.

6. Dress Professionally and Be Punctual

First impressions matter. Dressing professionally and arriving on time for the interview demonstrates your respect for the company and the interviewers. Pay attention to your body language and maintain a positive and enthusiastic demeanor throughout the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Carbon Furnace Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.