Are you gearing up for an interview for a Carbon Paper Coating Machine Setter position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Carbon Paper Coating Machine Setter and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

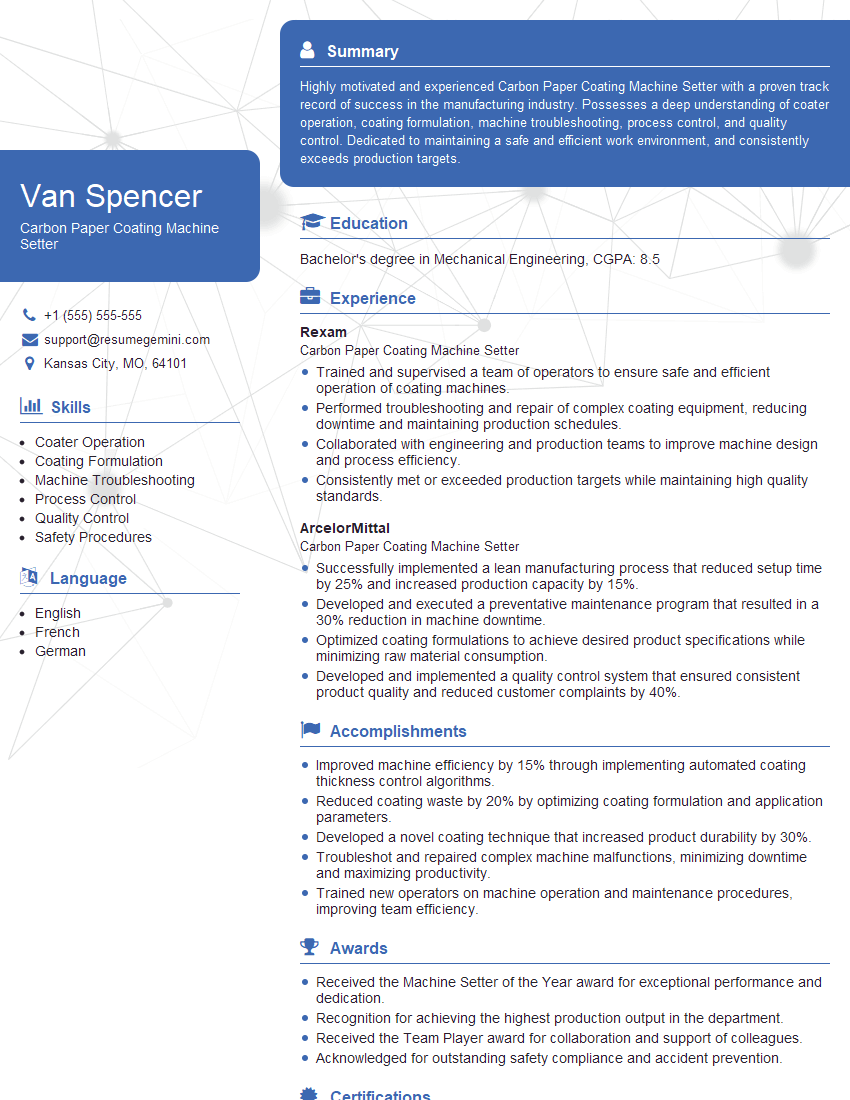

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carbon Paper Coating Machine Setter

1. How do you measure the thickness of the carbon paper coating?

- Use a micrometer to measure the coating thickness in micrometers (µm).

- Calibrate the micrometer regularly to ensure accuracy.

- Take multiple readings at different locations to get an average value.

2. What are the key factors that affect the quality of the carbon paper coating?

Coating composition

- Use high-quality carbon black and binders.

- Optimize the ratio of carbon black to binder for desired coating properties.

Substrate preparation

- Ensure the paper surface is clean and free of oil or contaminants.

- Pretreat the paper to improve coating adhesion.

Coating process

- Control the coating speed, temperature, and pressure.

- Use a suitable coating method (e.g., blade coating, roll coating).

3. What are the common troubleshooting steps for carbon paper coating issues?

- Identify the specific coating defect (e.g., uneven coating, poor adhesion).

- Check coating parameters and adjust as necessary.

- Inspect the substrate and coating materials for any contaminants or defects.

- Calibrate coating equipment to ensure proper operation.

- Consult with coating experts or equipment manufacturers for additional assistance.

4. How do you optimize the coating process for different types of carbon paper applications?

- Consider the specific requirements of the application (e.g., thickness, conductivity).

- Adjust coating parameters (e.g., speed, temperature) to achieve desired results.

- Use specialized coating techniques (e.g., micro-coating) for precise coating control.

5. What safety precautions should be taken when working with carbon paper coating materials?

- Wear appropriate protective gear (e.g., gloves, mask, eye protection).

- Handle carbon black carefully to avoid inhalation or skin contact.

- Keep the work area well-ventilated and free of dust.

- Follow manufacturer’s guidelines for safe handling and disposal.

6. How do you maintain and calibrate coating equipment to ensure optimal performance?

- Regularly clean and inspect coating equipment to prevent contamination.

- Calibrate coating heads and sensors to maintain accuracy.

- Use calibration standards to verify equipment performance.

- Follow manufacturer’s maintenance schedule for specific equipment.

7. What are the latest advancements in carbon paper coating technology?

- Nano-coating techniques to improve coating uniformity and durability.

- Development of environmentally friendly coating materials with reduced VOC emissions.

- Automated coating systems for higher efficiency and consistency.

8. How do you manage downtime during coating operations?

- Identify the cause of downtime (e.g., equipment failure, material shortage).

- Prioritize repairs or corrective actions to minimize downtime.

- Implement preventive maintenance strategies to reduce unplanned downtime.

9. How do you work effectively as part of a team in a carbon paper coating production environment?

- Communicate clearly and collaborate with other team members.

- Share knowledge and expertise to improve overall team performance.

- Provide support and assistance to colleagues as needed.

- Adapt to changing priorities and work together to meet deadlines.

10. How do you stay up-to-date on the latest developments in carbon paper coating industry?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Collaborate with experts and research institutions.

- Seek training and certification opportunities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carbon Paper Coating Machine Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carbon Paper Coating Machine Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Carbon Paper Coating Machine Setters are responsible for setting up, operating, and maintaining carbon paper coating machines to produce carbon paper. They must have a strong understanding of the principles of carbon paper coating and the operation of coating machines. Key job responsibilities include:

1. Machine Setup and Operation

Setting up the coating machine according to specifications, including installing and adjusting coating heads, rollers, and other components.

- Operating the coating machine to apply a uniform coating of carbon to the paper.

- Monitoring the coating process to ensure that the desired coating thickness and quality are achieved.

2. Quality Control

Inspecting the coated paper for defects and taking corrective action as needed.

- Testing the coated paper to ensure that it meets the required specifications.

- Maintaining quality control records.

3. Maintenance and Troubleshooting

Performing routine maintenance on the coating machine, including cleaning and lubricating parts.

- Troubleshooting and repairing the coating machine when problems occur.

- Ordering and installing replacement parts.

4. Safety

Following all safety procedures and regulations.

- Wearing personal protective equipment.

- Maintaining a clean and safe work area.

Interview Tips

Here are some interview tips to help you ace your interview for a Carbon Paper Coating Machine Setter position:

1. Research the Company and the Position

Take the time to learn about the company you’re applying to and the specific position you’re interested in. This will help you to better understand the company’s culture and values, and to tailor your answers to the interviewer’s questions.

- Visit the company’s website.

- Read articles about the company in industry publications.

- Talk to people in your network who work for the company.

2. Prepare for Common Interview Questions

There are a number of common interview questions that you’re likely to be asked, such as:

- “Tell me about your experience with carbon paper coating machines.”

- “What are your strengths and weaknesses as a Carbon Paper Coating Machine Setter?”

- “Why are you interested in working for this company?”

Take some time to prepare your answers to these questions in advance. Be honest and concise, and provide specific examples to support your answers.

3. Be Enthusiastic and Confident

Employers are looking for candidates who are enthusiastic about the position and who are confident in their abilities. Show your passion for the job by asking thoughtful questions about the company and the position. Be confident in your answers, and don’t be afraid to share your ideas.

4. Be Professional

Dress professionally and arrive on time for your interview. Be respectful of the interviewer and their time. Answer questions honestly and directly, and avoid interrupting or talking over the interviewer.

5. Follow Up

After your interview, send a thank-you note to the interviewer. This is a great way to show your appreciation for the opportunity to interview, and to reiterate your interest in the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Carbon Paper Coating Machine Setter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.