Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Carbon Paste Mixer Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

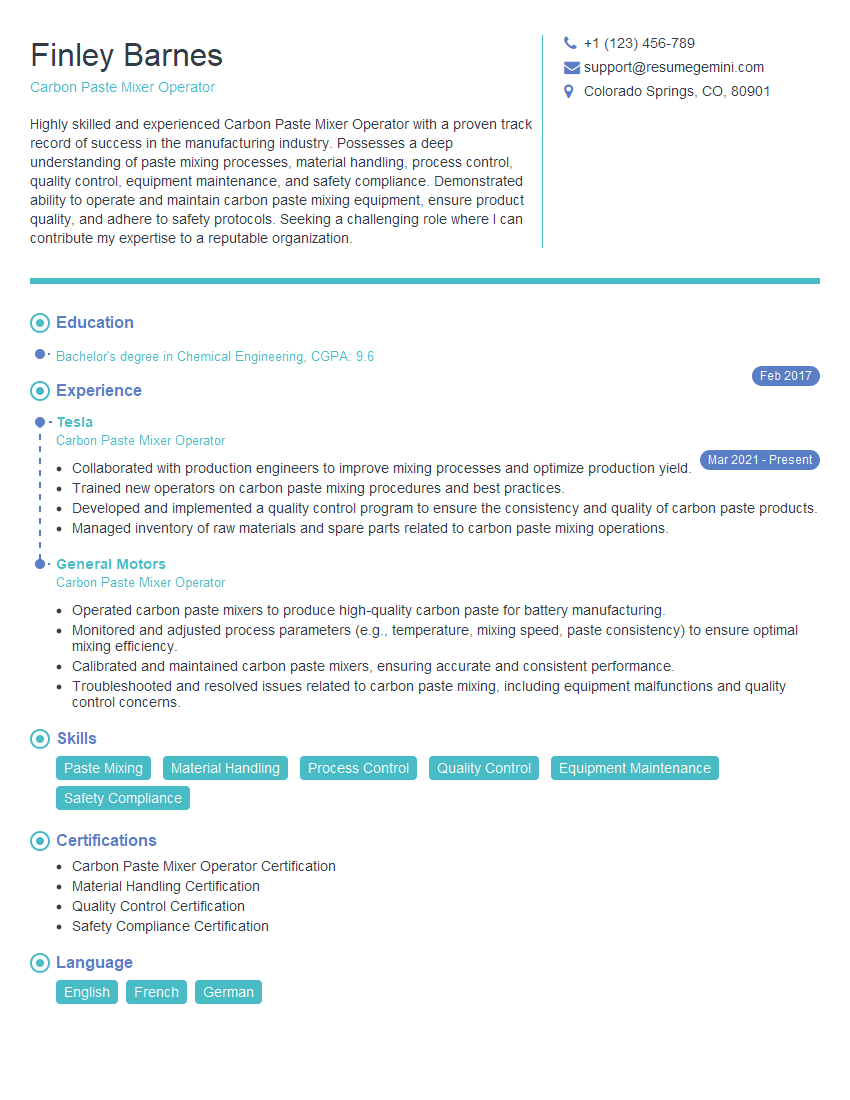

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carbon Paste Mixer Operator

1. Explain the process of carbon paste preparation in detail.

- Initial weighing and mixing

- Carbonization

- Final mixing and shaping

- Quality control and testing

2. What are the key parameters to control during carbon paste preparation?

Composition

- Carbon content

- Binder amount

- Additives

Processing

- Mixing time and speed

- Carbonization temperature and duration

- Cooling rate

3. How do you ensure the uniformity and consistency of the carbon paste?

- Use standardized equipment and procedures

- Calibrate equipment regularly

- Follow written operating procedures (SOPs)

- Conduct regular quality checks

4. What are the common defects that can occur during carbon paste preparation?

- Cracking

- Porosity

- Inhomogeneity

- Incorrect composition

5. How do you troubleshoot and resolve problems that arise during carbon paste preparation?

- Identify the problem and gather data

- Analyze the data to identify the root cause

- Develop and implement corrective actions

- Monitor and evaluate the effectiveness of the corrective actions

6. What are the safety considerations when working with carbon paste?

- Wear appropriate personal protective equipment (PPE)

- Work in a well-ventilated area

- Handle carbon paste with care to avoid spills and dust

- Follow safe disposal procedures

7. What is the role of a Carbon Paste Mixer Operator in a production facility?

Responsible for operating and maintaining carbon paste mixing equipment

Ensuring the production of high-quality carbon paste

Performing quality control checks

Troubleshooting and resolving problems

8. What are the key skills and qualifications required for a successful Carbon Paste Mixer Operator?

- High school diploma or equivalent

- 1-2 years of experience in a manufacturing or production environment

- Strong attention to detail

- Ability to work independently and as part of a team

- Good communication and interpersonal skills

9. How do you stay up-to-date with the latest technologies and developments in carbon paste preparation?

- Attend industry conferences and workshops

- Read technical journals and publications

- Participate in professional development programs

10. What are your career goals and aspirations?

To contribute to the production of high-quality carbon paste products

To advance my career in the manufacturing industry

To develop my skills and knowledge in carbon paste preparation

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carbon Paste Mixer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carbon Paste Mixer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Carbon Paste Mixer Operator is responsible for operating carbon paste mixers to produce carbon paste for use in aluminum electrolysis. Key responsibilities include:

1. Mixing Carbon Paste

Follows established procedures to mix carbon paste according to specified formulations.

- Weighs and measures raw materials, including petroleum coke, calcined coke, and binder.

- Loads raw materials into the mixer and controls the mixing process.

- Monitors the mixing process to ensure that the carbon paste meets the desired specifications.

2. Operating and Maintaining Equipment

Ensures the smooth and efficient operation of carbon paste mixers.

- Performs routine maintenance and repairs on mixers.

- Troubleshoots and resolves any problems that may arise during the mixing process.

- Keeps the mixing area clean and organized.

3. Quality Control

Monitors the quality of the carbon paste produced.

- Conducts quality control tests on the carbon paste to ensure that it meets specifications.

- Records and documents quality control data.

- Provides feedback to the production team on any quality issues.

4. Safety and Environmental Compliance

Adheres to all safety and environmental regulations.

- Wears appropriate personal protective equipment (PPE).

- follows established safety procedures.

- reports any safety or environmental concerns to management.

Interview Tips

To prepare for an interview for a Carbon Paste Mixer Operator position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s website, industry reputation, and the specific responsibilities of the Carbon Paste Mixer Operator role.

- Research the company’s history, mission, and values.

- Review the job description thoroughly and identify the key requirements.

2. Highlight Relevant Experience

In your resume and interview, emphasize your experience in operating and maintaining industrial machinery, particularly in the manufacturing or chemical processing industry.

- Quantify your accomplishments and use specific examples to demonstrate your skills.

- Focus on transferable skills, such as problem-solving, attention to detail, and teamwork.

3. Prepare for Technical Questions

Expect to answer questions about the carbon paste mixing process, equipment operation, and quality control procedures.

- Review basic principles of carbon paste mixing and the role of different raw materials.

- Practice troubleshooting common problems that may occur during the mixing process.

4. Demonstrate Safety Awareness

Emphasize your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Describe your experience with personal protective equipment (PPE) and safety procedures.

- explain how you would handle potential hazards in the workplace.

5. Practice Your Communication Skills

Be prepared to communicate clearly and effectively both verbally and in writing.

- practice answering interview questions in a concise and professional manner.

- prepare questions to ask the interviewer, demonstrating your interest in the company and the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Carbon Paste Mixer Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.