Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Carbonation Equipment Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Carbonation Equipment Tender so you can tailor your answers to impress potential employers.

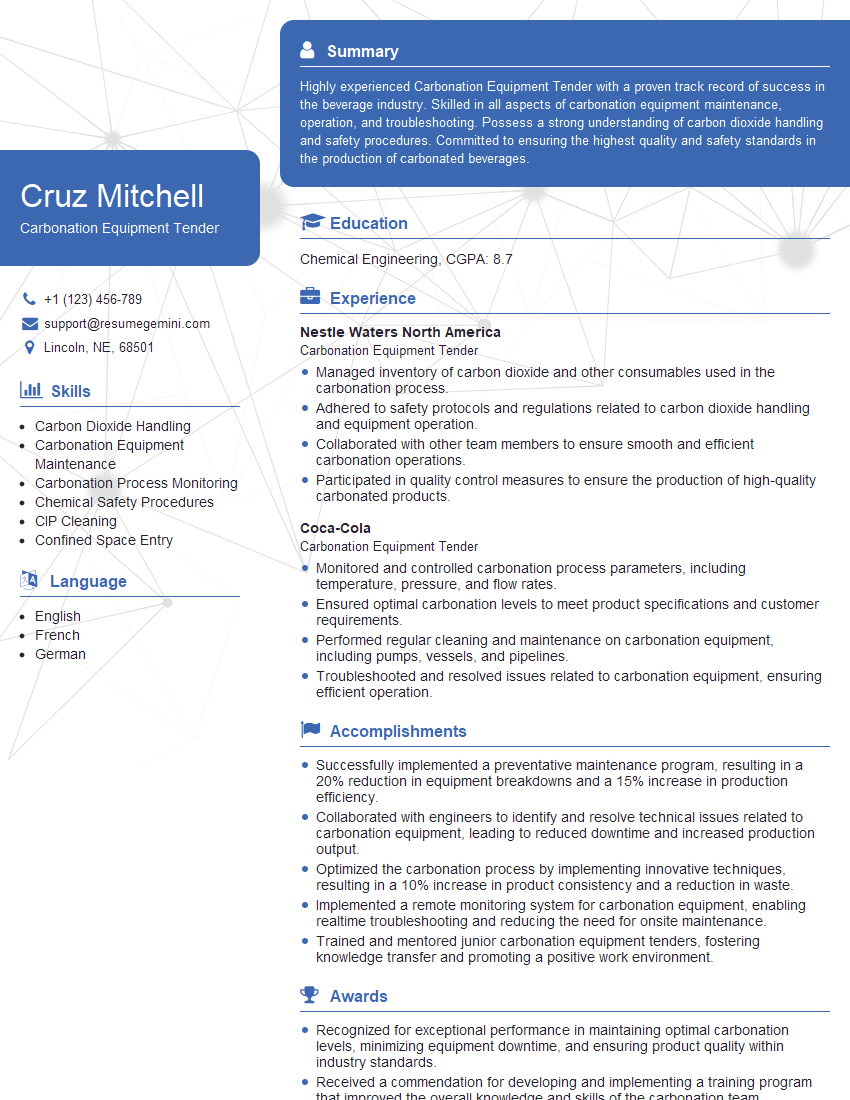

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carbonation Equipment Tender

1. Describe the key components of a carbonation system and explain their functions.

A carbonation system typically consists of the following key components:

- Carbon dioxide (CO2) source: This can be a compressed gas cylinder, a bulk liquid CO2 tank, or a CO2 generator.

- Pressure regulator: This device reduces the high pressure of the CO2 source to a lower pressure that is suitable for carbonating the liquid.

- Carbonation stone: This is a porous stone that is placed in the liquid to allow the CO2 to dissolve into it.

- Carbonation vessel: This is the tank or vessel in which the liquid is carbonated.

- Temperature control system: This system is used to maintain the desired temperature of the liquid during carbonation.

- Monitoring and control system: This system is used to monitor and control the various parameters of the carbonation process, such as the CO2 pressure, temperature, and flow rate.

2. What are the different types of carbonation equipment and how do they compare?

There are two main types of carbonation equipment:

Inline carbonation

- In this method, the CO2 is injected directly into the liquid as it flows through a pipe or tube.

- This method is typically used for large-scale carbonation of beverages.

- The advantage of inline carbonation is that it is a continuous process, which can result in higher production rates.

Batch carbonation

- In this method, the CO2 is injected into a closed vessel containing the liquid.

- The vessel is then pressurized and the CO2 is allowed to dissolve into the liquid over a period of time.

- This method is typically used for small-scale carbonation of beverages or for carbonating specialty products.

- The advantage of batch carbonation is that it allows for more precise control over the carbonation level.

3. What are the key factors to consider when selecting carbonation equipment?

When selecting carbonation equipment, the following key factors should be considered:

- The desired carbonation level

- The volume of liquid to be carbonated

- The type of liquid to be carbonated

- The available space

- The budget

4. What are the common problems that can occur with carbonation equipment and how can they be solved?

Some common problems that can occur with carbonation equipment include:

- Leaking CO2: This can be caused by a faulty pressure regulator or a leak in the carbonation vessel.

- Insufficient carbonation: This can be caused by a low CO2 pressure, a clogged carbonation stone, or a high temperature.

- Excessive carbonation: This can be caused by a high CO2 pressure or a low temperature.

- Foam formation: This can be caused by a high CO2 pressure or a low temperature.

These problems can be solved by:

- Checking the pressure regulator and carbonation vessel for leaks

- Increasing the CO2 pressure, cleaning the carbonation stone, or decreasing the temperature

- Decreasing the CO2 pressure or increasing the temperature

- Decreasing the CO2 pressure or increasing the temperature

5. What are the safety precautions that should be taken when operating carbonation equipment?

The following safety precautions should be taken when operating carbonation equipment:

- Always wear appropriate personal protective equipment, including safety glasses, gloves, and a lab coat.

- Never exceed the maximum pressure rating of the carbonation vessel.

- Do not operate the carbonation equipment in a confined space.

- Be aware of the potential for CO2 leaks and have a plan in place to deal with them.

- Never attempt to repair the carbonation equipment yourself. Always contact a qualified technician.

6. What are the maintenance requirements for carbonation equipment?

The maintenance requirements for carbonation equipment include:

- Regular inspection of the equipment for leaks and other damage.

- Cleaning the carbonation stone and other components as needed.

- Calibrating the pressure regulator and other instruments.

- Replacing worn or damaged parts as needed.

7. What are the current trends in carbonation equipment?

Some of the current trends in carbonation equipment include:

- The use of more efficient and environmentally friendly CO2 sources, such as CO2 generators.

- The development of new carbonation technologies that can achieve higher levels of carbonation with less CO2.

- The integration of carbonation equipment with other beverage production processes, such as filling and packaging.

8. What is the future of carbonation equipment?

The future of carbonation equipment is likely to see continued innovation in the areas of efficiency, environmental friendliness, and integration with other beverage production processes.

Some of the specific developments that may be seen in the future include:

- The development of new CO2 sources that are even more efficient and environmentally friendly than current technologies.

- The development of new carbonation technologies that can achieve even higher levels of carbonation with less CO2.

- The integration of carbonation equipment with other beverage production processes to create more efficient and automated production lines.

9. What are your strengths and weaknesses as a Carbonation Equipment Tender?

Some of my strengths as a Carbonation Equipment Tender include:

- I have a strong understanding of the principles of carbonation and the operation of carbonation equipment.

- I have experience in the installation, maintenance, and repair of carbonation equipment.

- I am familiar with the safety regulations governing the operation of carbonation equipment.

- I am a team player and I am always willing to help out my colleagues.

Some of my weaknesses as a Carbonation Equipment Tender include:

- I am not as experienced as some other candidates in the field.

- I do not have a formal degree in engineering or a related field.

- I am not always the most organized person.

However, I am confident that I can overcome these weaknesses and become a valuable asset to your team.

10. Why should we hire you as a Carbonation Equipment Tender?

I believe that I am the best candidate for the position of Carbonation Equipment Tender because I have the following skills and experience:

- I have a strong understanding of the principles of carbonation and the operation of carbonation equipment.

- I have experience in the installation, maintenance, and repair of carbonation equipment.

- I am familiar with the safety regulations governing the operation of carbonation equipment.

- I am a team player and I am always willing to help out my colleagues.

In addition, I am confident that I can quickly learn the specific requirements of your company and become a valuable member of your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carbonation Equipment Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carbonation Equipment Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Carbonation Equipment Tenders are responsible for ensuring the safe and efficient operation of carbonation equipment in breweries, beverage plants, and other food and beverage manufacturing facilities. Their duties include maintaining, repairing, and troubleshooting equipment, as well as ensuring that it meets all applicable safety and quality standards.

1. Maintain and Repair Carbonation Equipment

Tenders perform regular maintenance and repairs on carbonation equipment, including pumps, tanks, valves, and piping. They also conduct inspections and tests to verify that the equipment is operating properly and safely.

- Inspect and clean equipment regularly

- Troubleshoot and repair equipment as needed

- Replace worn or damaged parts

- Lubricate moving parts

2. Ensure Equipment Compliance

Tenders ensure that all carbonation equipment meets applicable safety and quality standards. They conduct inspections and tests to verify that the equipment is operating properly and safely. They also work with engineers and other plant personnel to ensure that the equipment is compliant with all regulatory requirements.

- Maintain equipment logs

- Document all maintenance and repairs

- Adhere to all safety protocols

- Work with engineers and other plant personnel to improve equipment performance

3. Train and Supervise Others

In some cases, Tenders may be responsible for training and supervising other employees. They provide instruction on the safe and efficient operation of carbonation equipment and ensure that all employees are following proper procedures.

- Train new employees on equipment operation

- Supervise employees and ensure that they are following proper procedures

- Provide feedback to employees on their performance

- Help to resolve any issues that may arise

4. Other Responsibilities

In addition to the above responsibilities, Tenders may also be responsible for other tasks, such as:

- Ordering supplies and materials

- Keeping inventory of equipment and supplies

- Participating in safety meetings

- Assisting with plant maintenance and repairs

Interview Tips

Preparing for an interview for a Carbonation Equipment Tender position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company and the Position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, its products or services, and the specific responsibilities of the role. You can find this information on the company’s website, in industry publications, or by speaking with people in your network.

2. Practice Your Answers

Once you have a good understanding of the company and the position, start practicing your answers to common interview questions. This will help you feel more confident and prepared during your interview. Some common interview questions for Carbonation Equipment Tenders include:

- Tell me about your experience with carbonation equipment.

- What are your strengths and weaknesses as a Carbonation Equipment Tender?

- Why are you interested in this position?

- What are your salary expectations?

3. Be Professional

First impressions matter, so make sure to dress professionally and arrive on time for your interview. Be polite and respectful to everyone you meet, including the receptionist, the interviewer, and other employees. Remember to maintain eye contact and speak clearly and confidently.

4. Follow Up

After your interview, send a thank-you note to the interviewer. This is a great way to reiterate your interest in the position and thank the interviewer for their time. You can also use this opportunity to highlight any specific skills or experience that you feel would make you a valuable asset to the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Carbonation Equipment Tender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Carbonation Equipment Tender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.