Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Carburetor Rebuilder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Carburetor Rebuilder so you can tailor your answers to impress potential employers.

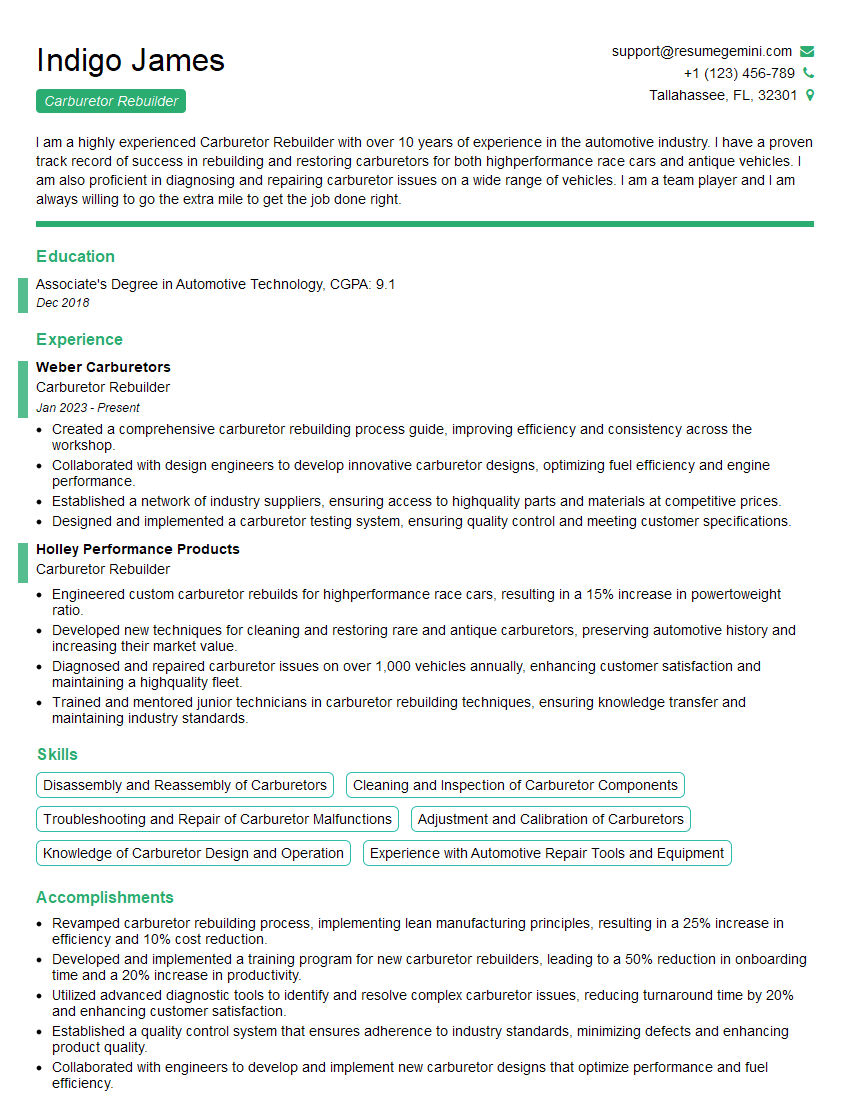

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carburetor Rebuilder

1. What are the different types of carburetors and their applications?

There are various types of carburetors, each designed for specific applications. Here are some common types:

- Single-barrel carburetor: Used in small engines, such as lawnmowers and motorcycles, with a simple design and one barrel.

- Two-barrel carburetor: Found in older vehicles, with two barrels that open in sequence to provide more airflow.

- Four-barrel carburetor: Used in high-performance engines, with four barrels that open in pairs for increased airflow.

- Computer-controlled carburetor: Utilizing electronic controls to adjust fuel-air mixture, ensuring optimal engine performance.

2. Explain the working principle of a float-style carburetor.

A float-style carburetor operates on the principle of maintaining a constant fuel level in the float chamber:

- Fuel inlet valve: Controls the flow of fuel into the float chamber.

- Float: A device that rises and falls with the fuel level, actuating the fuel inlet valve.

- Fuel jet: A nozzle that discharges fuel into the carburetor venturi.

- Venturi: A constriction in the carburetor throat that creates a low-pressure area, drawing fuel from the jet.

3. Describe the process of rebuilding a carburetor and the tools required.

Rebuilding a carburetor involves the following steps:

- Disassembly: Taking apart the carburetor and cleaning each component.

- Inspection: Examining parts for wear or damage, and replacing if necessary.

- Reassembly: Putting the carburetor back together and ensuring all parts are properly aligned.

- Adjustment: Fine-tuning the carburetor to achieve optimal fuel flow and engine performance.

- Screwdrivers

- Wrenches

- Carb cleaner

- Rebuild kit

4. How do you troubleshoot a faulty carburetor?

Troubleshooting a carburetor involves identifying symptoms and performing systematic checks:

- Check fuel flow: Ensure fuel is reaching the carburetor and the fuel filter is clean.

- Inspect float: Verify the float is properly adjusted and not damaged, causing fuel level issues.

- Clean jets: Clogged jets can restrict fuel flow and cause performance problems.

- Examine throttle linkage: Ensure the linkage is operating smoothly and not binding.

5. What are the safety precautions to follow when handling carburetor cleaner?

Carburetor cleaner is a flammable and toxic substance, so safety precautions must be followed:

- Use in a well-ventilated area: Avoid inhaling fumes.

- Wear gloves and eye protection: Prevent skin and eye contact.

- Keep away from open flames: Carburetor cleaner is flammable.

- Dispose of properly: Do not pour carburetor cleaner into drains or the environment.

6. Explain the differences between a mechanical and an electric choke.

Mechanical choke:

- Operates using a bimetallic spring that senses engine temperature.

- When the engine is cold, the choke closes to provide a richer fuel-air mixture.

- As the engine warms up, the spring relaxes and the choke opens.

Electric choke:

- Utilizes a heating element to warm a thermostatic coil, which controls the choke.

- When the engine is cold, the heating element is activated, closing the choke.

- As the engine warms up, the heating element turns off, allowing the choke to open.

7. Describe the function of carburetor jets and how to adjust them.

Carburetor jets are nozzles that control the flow of fuel into the carburetor venturi:

- Main jet: Regulates fuel flow at high speeds.

- Slow jet: Controls fuel flow at idle and low speeds.

- Air jets: Adjust the amount of air mixed with fuel, affecting engine performance.

Adjustment involves changing the size or shape of the jets to fine-tune the fuel-air mixture for optimal performance.

8. What are the signs of a worn or damaged carburetor?

Symptoms of carburetor issues may include:

- Engine hesitation or stumbling during acceleration

- Black smoke from the exhaust, indicating a rich mixture

- Excessive fuel consumption

- Difficulty starting the engine

- Uneven idle or stalling

9. Explain the importance of synchronizing carburetors in multiple-carburetor systems.

In multiple-carburetor setups, synchronization ensures that:

- Balanced airflow: Each carburetor provides the same amount of air to the engine.

- Optimal fuel distribution: Fuel is evenly distributed among the cylinders.

- Improved engine performance: Synchronization prevents uneven fuel-air mixtures and ensures smooth operation.

- Reduced emissions: Proper synchronization helps reduce exhaust emissions.

10. What are the advancements in carburetor technology, such as fuel injection and electronic fuel management?

Advancements in carburetor technology include:

- Fuel injection: Replaces carburetors with electronic fuel injectors, providing precise fuel metering and improved performance.

- Electronic fuel management systems: Utilize sensors and computer controls to optimize fuel-air mixture and engine operation.

- Variable-venturi carburetors: Adjust the venturi size to improve airflow and fuel delivery at different engine speeds.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carburetor Rebuilder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carburetor Rebuilder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Carburetor Rebuilder is responsible for diagnosing, repairing, and rebuilding carburetors, ensuring they are restored to their original working condition.

1. Inspect Carburetors

Inspect carburetors visually and using diagnostic tools, such as flow meters and vacuum gauges, to identify potential issues

- Analyze engine performance data, such as fuel consumption and emissions, to identify carburetor-related problems.

- Disassemble carburetors into components, ensuring all parts are removed and accounted for.

2. Diagnose and Repair Carburetor Issues

Diagnose common carburetor problems, such as fuel flow blockages, sticking valves, and damaged jets

- Replace worn-out or damaged carburetor components, such as gaskets, floats, and springs.

- Adjust carburetor settings to ensure optimal performance and fuel economy.

3. Reassemble and Test Carburetors

Reassemble carburetors using precision tools and techniques, ensuring all components are correctly positioned and secured

- Test the performance of rebuilt carburetors using a variety of testing equipment, such as dynamometers and emission analyzers.

- Document all repairs and adjustments made to each carburetor.

4. Maintain Work Area and Equipment

Maintain a clean and organized work area, ensuring proper disposal of hazardous materials.

- Keep tools and equipment in good working condition, ensuring regular calibration and maintenance.

- Maintain inventory of carburetor parts and supplies.

Interview Tips

Interview preparation is key to making a good impression and increasing your chances of success. Here are some tips to prepare for a Carburetor Rebuilder interview:

1. Research the Company and Position

Learn about the company’s history, values, and products, and understand the specific requirements of the Carburetor Rebuilder position.

- Visit the company’s website, read industry publications, and connect with current or former employees on LinkedIn.

- Identify keywords from the job description and tailor your resume and cover letter accordingly.

2. Practice Your Answers to Common Interview Questions

Research common interview questions for the Carburetor Rebuilder position and practice your answers.

- Prepare examples of your experience in diagnosing and repairing carburetors.

- Highlight your knowledge of carburetor components and principles of operation.

3. Emphasize Your Skills and Experience

During the interview, clearly articulate your skills and experience that are relevant to the Carburetor Rebuilder position.

- Use specific examples to showcase your ability to diagnose, repair, and rebuild carburetors.

- Quantify your accomplishments whenever possible, using metrics such as the number of carburetors rebuilt or the percentage of repairs completed within a specific timeframe.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement.

- Ask about the company’s goals for the Carburetor Rebuilder position and how your skills can contribute to those goals.

- Inquire about the company’s commitment to training and professional development for employees.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Carburetor Rebuilder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.