Feeling lost in a sea of interview questions? Landed that dream interview for Carburizing Furnace Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Carburizing Furnace Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

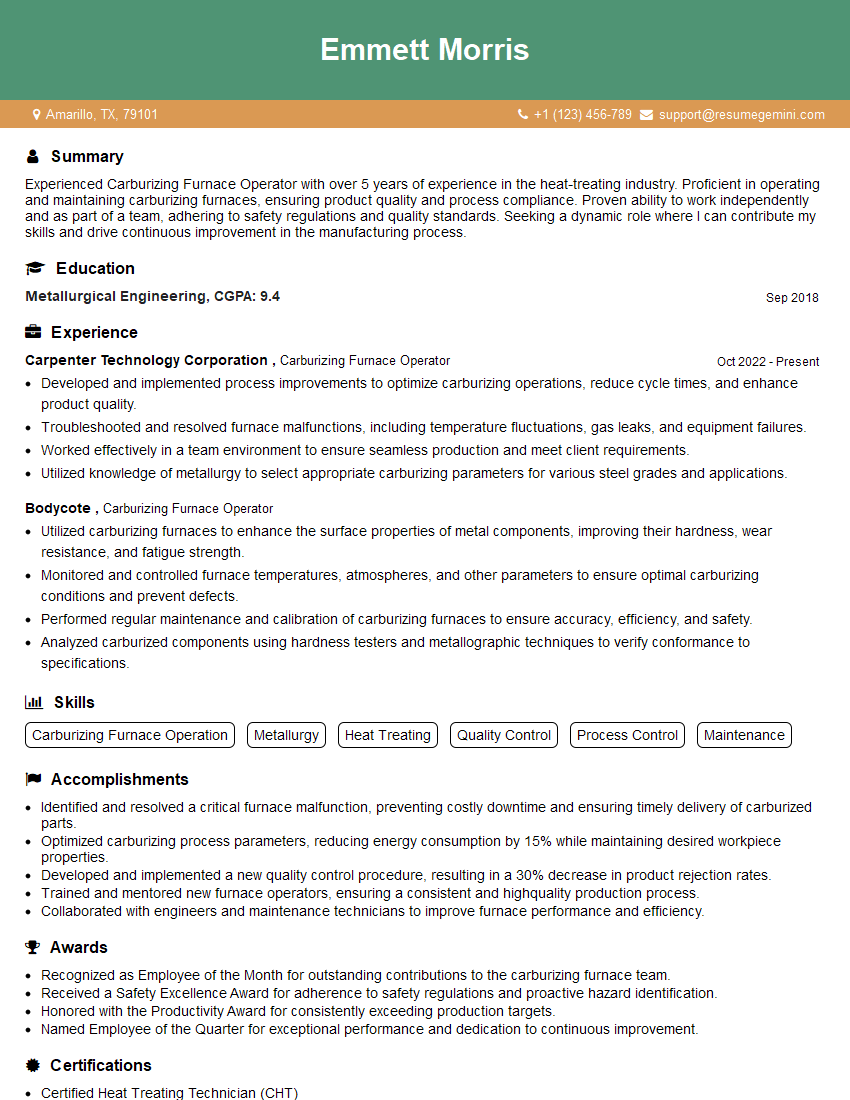

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carburizing Furnace Operator

1. Describe the carburizing process in detail.

- Carburizing is a heat treatment process in which the surface of a metal is enriched with carbon by diffusion.

- The process involves heating the metal in a carbon-rich atmosphere, such as a gas or plasma, at a temperature below the melting point of the metal.

- The carbon atoms then diffuse into the surface of the metal, forming a hard, wear-resistant layer.

2. What are the different types of carburizing furnaces?

There are two main types of carburizing furnaces: batch furnaces and continuous furnaces.

Batch furnaces

- Batch furnaces are used to heat treat small to medium-sized batches of parts.

- The parts are placed in a furnace chamber and heated to the desired temperature.

- The furnace chamber is then sealed and a carbon-rich gas is introduced.

Continuous furnaces

- Continuous furnaces are used to heat treat large batches of parts.

- The parts are continuously fed into the furnace chamber and heated to the desired temperature.

- The parts are then passed through a carbon-rich atmosphere before being cooled.

3. What are the factors that affect the carburizing process?

- The temperature of the furnace

- The carbon content of the atmosphere

- The time spent in the furnace

- The type of metal being carburized

4. What are the advantages of carburizing?

- Increases the hardness and wear resistance of the surface of the metal

- Improves the fatigue strength of the metal

- Reduces friction and wear

5. What are the disadvantages of carburizing?

- Can cause distortion of the metal

- Can lead to the formation of carbides, which can make the metal brittle

- Can be expensive

6. What are the safety precautions that must be taken when operating a carburizing furnace?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a respirator

- Ensure that the furnace is properly ventilated

- Do not enter the furnace chamber while it is in operation

- Handle hot parts with care

7. What are the maintenance tasks that need to be performed on a carburizing furnace?

- Regularly clean the furnace chamber and components

- Inspect the furnace for any damage

- Calibrate the furnace temperature controls

- Replace any worn or damaged parts

8. What are the troubleshooting steps that can be taken if a carburizing furnace is not operating properly?

- Check the furnace temperature controls

- Inspect the furnace for any damage

- Check the carbon content of the atmosphere

- Check the flow rate of the atmosphere

9. What are the quality control procedures that need to be followed for carburized parts?

- Inspect the parts for any defects, such as cracks, distortion, or pitting

- Measure the hardness of the surface of the parts

- Test the fatigue strength of the parts

10. What are the future trends in carburizing technology?

- The use of new materials, such as ceramic and composite materials, for carburizing

- The development of new carburizing processes, such as low-pressure carburizing and plasma carburizing

- The use of computer-controlled systems to optimize the carburizing process

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carburizing Furnace Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carburizing Furnace Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Carburizing Furnace Operator is responsible for operating and maintaining carburizing furnaces, which are used to heat treat metal parts to increase their hardness and wear resistance. Key responsibilities include:

1. Furnace Operation

Loading and unloading furnaces with metal parts.

Monitoring furnace temperature and atmosphere composition.

Adjusting furnace settings to ensure proper heat treatment.

2. Equipment Maintenance

Inspecting and cleaning furnaces regularly.

Performing minor repairs and adjustments.

Coordinating with maintenance personnel for major repairs.

3. Quality Control

Ensuring that parts meet specified hardness and surface quality requirements.

Conducting inspections and testing as needed.

Maintaining records of heat treatment parameters.

4. Safety

Following all safety procedures and regulations.

Wearing appropriate personal protective equipment.

Reporting any safety concerns promptly.

Interview Tips

To prepare for an interview for a Carburizing Furnace Operator position, consider the following tips:

1. Research the Company and Position

Learn about the company’s products, services, and culture.

Review the job description and identify the specific skills and experience required.

2. Highlight Relevant Experience

Emphasize your experience in furnace operation and maintenance.

Quantify your accomplishments with specific examples, such as reducing downtime or improving part quality.

3. Demonstrate Safety Awareness

Discuss your commitment to safety and your understanding of furnace safety procedures.

Describe how you have implemented safety measures in previous roles.

4. Show Your Attention to Detail

Explain how you ensure that parts meet specifications and quality standards.

Provide examples of your attention to detail and ability to follow instructions precisely.

5. Practice Answer Common Interview Questions

Prepare for common interview questions, such as:

- Tell me about your experience in operating carburizing furnaces.

- How do you ensure the safety of yourself and others when working with furnaces?

- What is your understanding of the different types of heat treatment processes?

- How do you stay up-to-date on the latest advances in furnace technology?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Carburizing Furnace Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.