Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Carding Utility Tender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

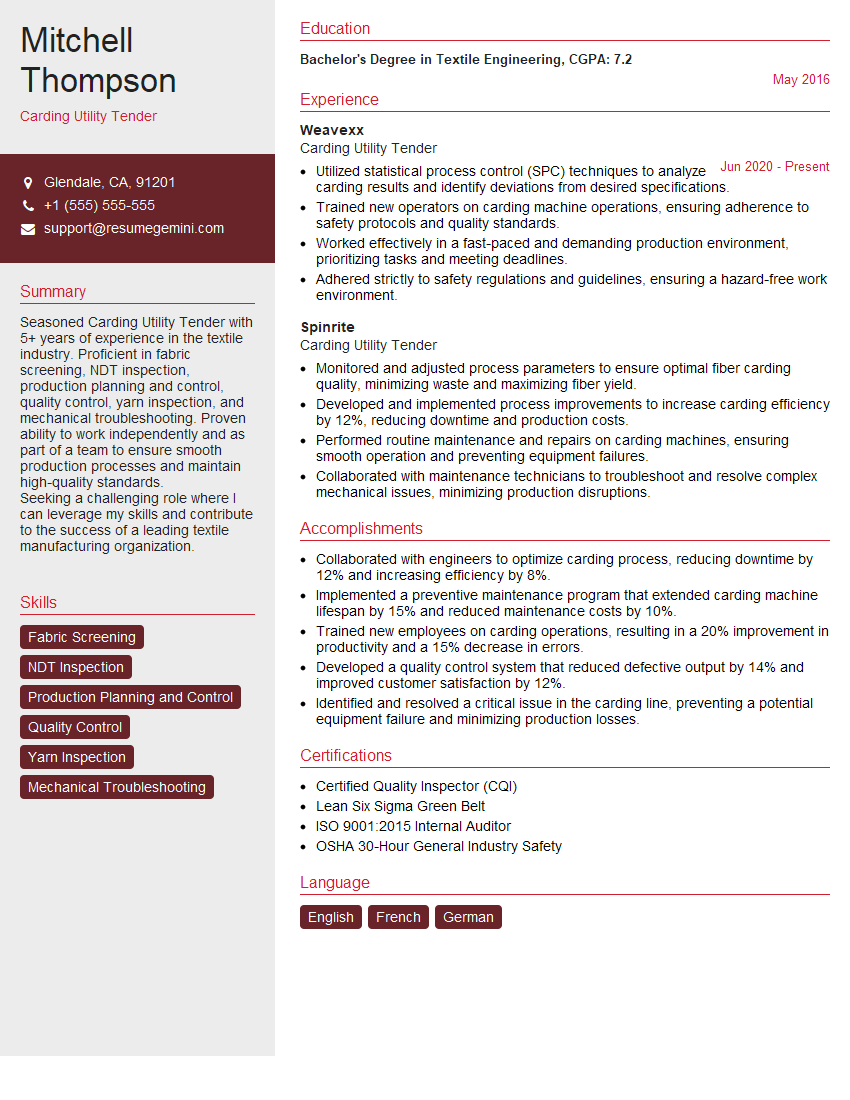

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carding Utility Tender

1. Explain the process of carding in a textile mill.

- The first step in carding is to open the bales of cotton and feed them into the carding machine.

- The carding machine uses a series of rollers to separate the fibers and remove any impurities.

- The fibers are then drawn into a thin sheet and passed through a series of rollers that have fine teeth.

- The teeth on the rollers remove any remaining impurities and align the fibers in the same direction.

- The carded fibers are then collected into a sliver, which is a continuous strand of fibers.

2. What are the different types of carding machines?

Flat carding machine

- A flat carding machine uses a flat surface to card the fibers.

- The fibers are fed onto the flat surface and are then carded by a series of rollers that have fine teeth.

Rotary carding machine

- A rotary carding machine uses a rotating cylinder to card the fibers.

- The fibers are fed onto the cylinder and are then carded by a series of rollers that have fine teeth.

3. What are the main adjustments that can be made to a carding machine?

- The speed of the rollers can be adjusted to change the rate at which the fibers are carded.

- The distance between the rollers can be adjusted to change the intensity of the carding action.

- The angle of the rollers can be adjusted to change the direction of the carding action.

- The weight of the rollers can be adjusted to change the pressure applied to the fibers.

4. What are the common problems that can occur during carding?

- The fibers can become tangled or broken if the rollers are set too close together.

- The fibers can be damaged if the rollers are set too far apart.

- The fibers can be unevenly carded if the rollers are not aligned properly.

- The fibers can be contaminated with impurities if the carding machine is not properly maintained.

5. What are the safety precautions that should be taken when operating a carding machine?

- Wear appropriate safety clothing, including gloves, safety glasses, and a dust mask.

- Keep the machine clean and free of debris.

- Do not operate the machine if it is not properly guarded.

- Do not reach into the machine while it is running.

- Be aware of the moving parts of the machine.

6. How do you maintain a carding machine?

- Clean the machine regularly to remove any debris or buildup.

- Inspect the rollers regularly for wear and tear.

- Lubricate the machine according to the manufacturer’s instructions.

- Calibrate the machine regularly to ensure that it is operating properly.

- Keep a maintenance log to track all maintenance activities.

7. What are the most important qualities of a good Carding Utility Tender?

- Attention to detail

- Mechanical aptitude

- Problem-solving skills

- Teamwork skills

- Safety consciousness

8. What is your experience with carding machines?

I have worked as a Carding Utility Tender for the past 5 years. In this role, I was responsible for the operation, maintenance, and repair of carding machines.

I have a strong understanding of the carding process and the different types of carding machines.

I am also proficient in troubleshooting and repairing carding machines.

9. What are your career goals?

I am looking to advance my career in the textile industry.

I am interested in learning more about the different aspects of textile manufacturing.

I am also interested in developing my leadership skills.

10. Why should we hire you for this position?

I am a highly qualified Carding Utility Tender with 5 years of experience.

I have a strong understanding of the carding process and the different types of carding machines.

I am also proficient in troubleshooting and repairing carding machines.

I am confident that I can make a significant contribution to your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carding Utility Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carding Utility Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Carding Utility Tender plays a crucial role in the smooth operation of textile machinery responsible for the initial stages of fiber processing. Key responsibilities of the position include:

1. Machinery Operation and Maintenance

Operating and monitoring carding machines, which separate and align fibers to create a cohesive web used in subsequent textile production processes

- Performing regular maintenance and cleaning of carding machines to ensure optimal performance

- Troubleshooting and resolving operational issues to minimize downtime and maintain production efficiency

2. Quality Control

Monitoring the quality of the processed fiber web and making adjustments to ensure it meets the required specifications

- Conducting quality checks and using testing equipment to assess fiber alignment, uniformity, and cleanliness

- Making necessary adjustments to machine settings based on quality control results to achieve desired output

3. Material Handling

Loading raw fiber into carding machines and removing processed fiber web to ensure a continuous production process

- Using material handling equipment to safely and efficiently transport raw materials and finished products

- Maintaining organized and clean work areas to prevent contamination and ensure safety

4. Safety Compliance

Adhering to safety protocols and guidelines to minimize risks and ensure a safe working environment

- Wearing appropriate personal protective equipment (PPE) and following established safety procedures

- Identifying potential hazards and taking appropriate preventive measures to mitigate risks associated with machinery operation

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of making a positive impression and securing the desired position. Here are some effective interview tips to help you ace your Carding Utility Tender interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and the specific role you are applying for. This knowledge will demonstrate your interest and enthusiasm for the opportunity.

- Visit the company’s website and review their mission statement, products, and services

- Read industry publications and articles to gain insights into the company’s market position and reputation

2. Highlight Relevant Experience and Skills

Tailor your resume and cover letter to emphasize the skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to demonstrate your impact.

- Highlight your previous experience operating and maintaining textile machinery, particularly carding machines

- Showcase your knowledge of quality control procedures and your ability to troubleshoot and resolve operational issues

3. Practice Common Interview Questions

Anticipate and prepare for common interview questions related to your experience, skills, and motivations. Practicing your responses will help you articulate your qualifications effectively.

- Prepare answers to questions about your experience in operating and maintaining carding machines

- Develop examples of how you have handled quality control issues and resolved operational challenges

4. Be Enthusiastic and Confident

Project a positive and confident demeanor throughout the interview. Enthusiasm for the role and the industry will make a lasting impression.

- Express your interest in the position and explain why you believe you are a suitable candidate

- Show your passion for the textile industry and your eagerness to contribute to the company’s success

5. Ask Thoughtful Questions

At the end of the interview, asking thoughtful questions demonstrates your engagement and interest in the role and the company.

- Ask about the company’s growth plans and their commitment to innovation

- Inquire about opportunities for professional development and advancement within the organization

Next Step:

Now that you’re armed with the knowledge of Carding Utility Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Carding Utility Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini