Are you gearing up for an interview for a Carpentry Specialist position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Carpentry Specialist and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

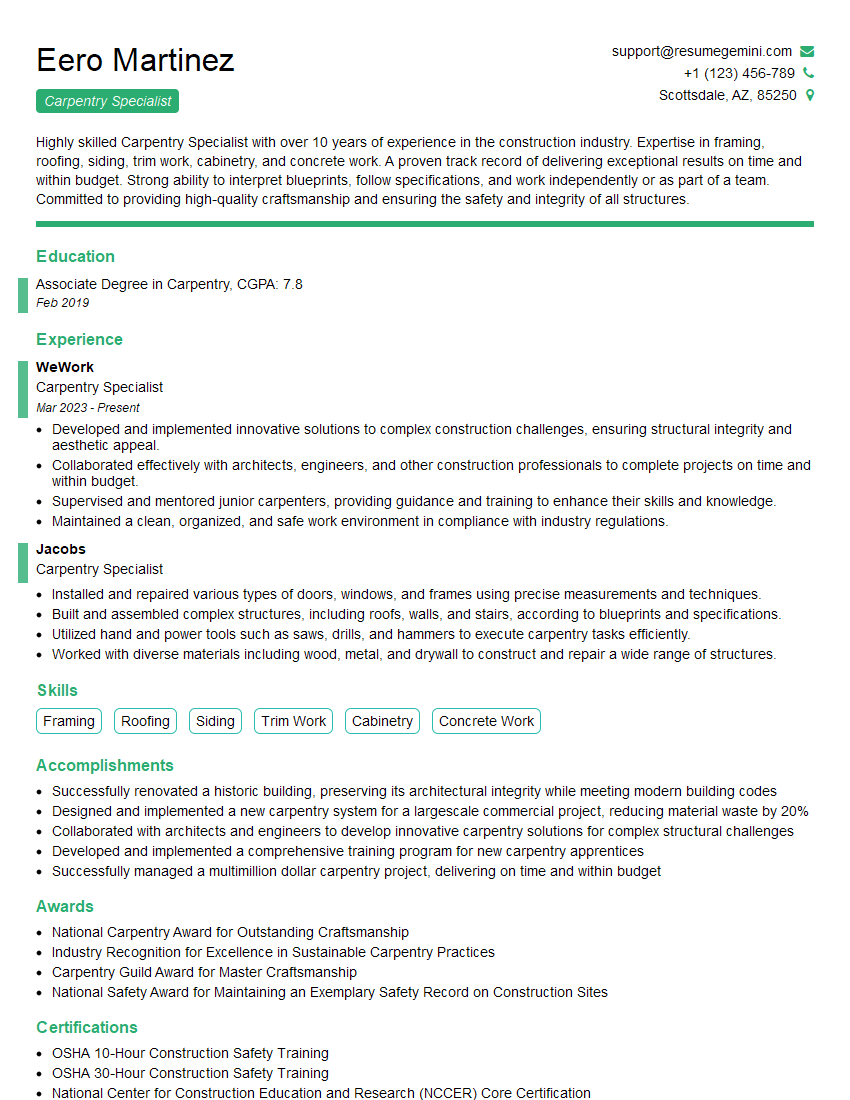

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carpentry Specialist

1. Describe the process of framing a wall.

The process of framing a wall involves several steps:

- Layout: Mark the location of the wall on the floor and ceiling using a chalk line or laser level.

- Cut studs: Cut the vertical studs to the desired length using a circular saw or miter saw.

- Assemble bottom plate: Lay the bottom plate on the floor and nail the studs to it at 16 or 24-inch intervals.

- Raise wall: Lift the assembled wall into place and nail it to the ceiling joists or top plate.

- Sheathing: Cover the wall with sheathing material, such as plywood or OSB, to provide structural support.

2. How do you ensure the accuracy of your cuts when using a circular saw?

Precision Cutting

- Use a sharp blade: Dull blades can cause splintering and inaccurate cuts.

- Calibrate the saw: Ensure that the blade is square to the base plate.

- Use a straight edge or guide: Hold a straight edge or guide along the cutting line to prevent the saw from drifting.

- Clamp the workpiece: Secure the workpiece firmly to prevent movement during cutting.

Safety Measures

- Wear safety gear: Use safety glasses, hearing protection, and dust masks.

- Maintain control of the saw: Hold the saw firmly with both hands and keep it under control.

- Inspect the cord and blade: Check for any damage or loose connections before operating the saw.

3. What are the different types of joinery techniques used in carpentry?

- Butt joint: Two pieces of wood are joined together end-to-end with no interlocking.

- Miter joint: Two pieces of wood are joined at an angle, typically 45 degrees, to form a corner.

- Rabbet joint: One piece of wood has a recess cut into it to receive another piece of wood.

- Dado joint: Similar to a rabbet joint, but the recess is cut across the grain of the wood.

- Mortise and tenon joint: A mortise (hole) is cut into one piece of wood to receive a tenon (projection) from another piece of wood, creating a strong and durable connection.

4. How do you choose the right type of wood for a specific project?

Factors to consider when choosing wood for a project include:

- Purpose: Determine the intended use of the project, such as structural framing, furniture, or outdoor applications.

- Durability: Consider the resistance of the wood to rot, decay, and wear.

- Strength: Select wood that is strong enough to support the required loads.

- Appearance: Choose wood with a grain pattern and color that complements the project’s design.

- Cost: Consider the budget for the project and select wood that is affordable.

5. What are the different types of roofing materials, and what are their advantages and disadvantages?

Asphalt Shingles

- Advantages: Affordable, easy to install, available in a variety of colors and textures.

- Disadvantages: Not as durable as some other materials, susceptible to damage from high winds.

Metal Roofing

- Advantages: Durable, fire-resistant, long-lasting.

- Disadvantages: More expensive than asphalt shingles, can be noisy during rain or hail.

Tile Roofing

- Advantages: Durable, fire-resistant, visually appealing.

- Disadvantages: Heavy, expensive to install, can be damaged by hail or falling objects.

6. How do you ensure proper drainage around a building?

- Grading: Slope the ground away from the foundation to prevent water from pooling.

- Gutter and downspouts: Install gutters and downspouts to collect and redirect rainwater away from the building.

- French drains: Dig trenches around the perimeter of the building and fill them with gravel to collect and drain excess water.

- Dry wells: Dig holes in the ground to collect and absorb water from heavy rainfall.

7. What are the safety precautions you take when working with power tools?

- Wear safety gear: Use safety glasses, hearing protection, and dust masks.

- Inspect tools before use: Check for any damage or loose connections.

- Use sharp blades: Dull blades can increase the risk of accidents.

- Keep cords and hoses away from moving parts: Prevent entanglement and potential injuries.

- Never operate power tools while under the influence of drugs or alcohol: Impaired judgment and coordination can increase the risk of accidents.

8. How do you level and plumb walls and floors?

Leveling Walls

- String method: Stretch a chalk line or string across the wall at the desired height.

- Laser level: Use a laser level to project a horizontal line onto the wall.

- Water level: Fill a clear tube with water and place it on the wall. The water level will indicate the true horizontal.

Plumbing Floors

- Plumb bob: Hang a plumb bob from the ceiling or a higher reference point.

- Laser level: Use a laser level to project a vertical line onto the floor.

- Carpenter’s level: Place a carpenter’s level on the floor and adjust the leveling bubbles to indicate verticality.

9. How do you calculate the area of a roof for material estimation?

- Flat roof: Length x Width

- Gable roof: (1/2 Length x Height) x 2 (for both sides)

- Hip roof: Sum of the areas of each triangular or trapezoidal section

- Mansard roof: Sum of the areas of the lower and upper trapezoidal sections

10. What are the building codes and regulations applicable to carpentry work?

- International Building Code (IBC): Provides minimum standards for building construction, including structural requirements, fire safety, and accessibility.

- National Electrical Code (NEC): Governs the installation and maintenance of electrical systems.

- American National Standards Institute (ANSI): Develops safety standards for various industries, including carpentry.

- Occupational Safety and Health Administration (OSHA): Enforces workplace safety regulations, including those related to carpentry work.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carpentry Specialist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carpentry Specialist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Carpentry Specialists are highly skilled craftspeople who specialize in various aspects of carpentry work. Their primary responsibilities include:

1. Project Planning and Execution

Planning and executing carpentry projects, including determining materials, labor, and equipment needs.

2. Material Selection and Usage

Selecting and using appropriate materials for carpentry projects, such as wood, steel, and composite materials.

- Understanding the properties and characteristics of different materials.

- Choosing materials based on the specific requirements of the project.

3. Construction and Installation

Constructing and installing carpentry components, such as framing, siding, and trim.

- Following building plans and specifications.

- Using specialized tools and equipment safely and efficiently.

- Ensuring the structural integrity and aesthetic appeal of the finished product.

4. Maintenance and Repair

Performing maintenance and repairs on existing carpentry structures.

- Identifying and diagnosing problems.

- Repairing or replacing damaged components.

- Ensuring the longevity and safety of the structure.

Interview Tips

To successfully ace the interview for a Carpentry Specialist position, candidates should:

1. Research the Company and Industry

Gather information about the company’s culture, values, and recent projects.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

- Network with other professionals in the field.

2. Highlight Relevant Skills and Experience

Emphasize your skills in carpentry techniques, material selection, and project management.

- Quantify your accomplishments using specific examples.

- Demonstrate your ability to work independently and as part of a team.

- Be prepared to discuss your knowledge of industry standards and best practices.

3. Prepare for Technical Questions

Expect questions related to carpentry techniques, materials, and safety protocols.

- Review common carpentry tools and equipment.

- Study different types of wood and their properties.

- Familiarize yourself with building codes and regulations.

4. Showcase Your Passion and Enthusiasm

Convey your passion for carpentry and your desire to contribute to the company’s success.

- Explain why you chose a career in carpentry.

- Share your experiences with previous carpentry projects.

- Express your willingness to learn and grow within the field.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Carpentry Specialist, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Carpentry Specialist positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.