Are you gearing up for an interview for a Carpet Sewing Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Carpet Sewing Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

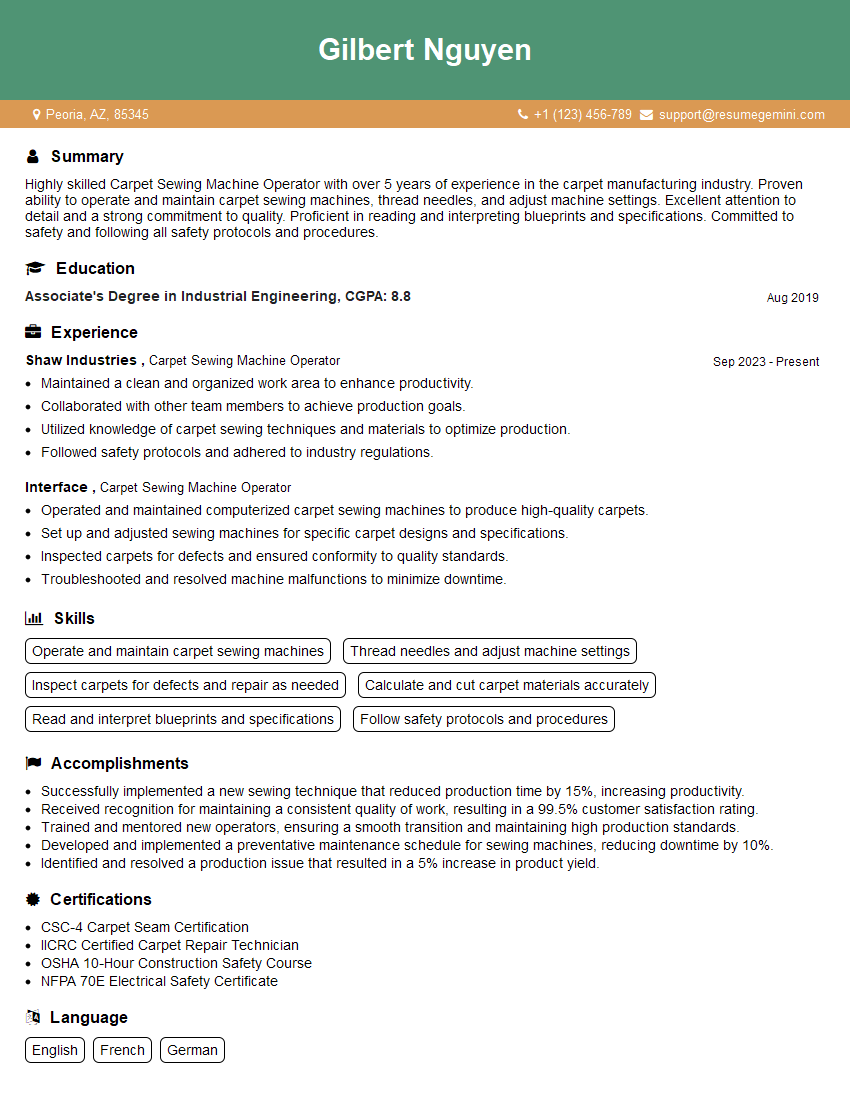

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carpet Sewing Machine Operator

1. Explain the process of setting up a carpet sewing machine for a specific stitching job.

- Determine the type of stitch required and select the appropriate needle.

- Adjust the tension and feed settings according to the carpet material and stitch type.

- Mount the carpet onto the sewing bed and secure it with clips or pins.

- Thread the machine and adjust the bobbin tension.

- Set the stitch length and width.

- Calibrate the machine using a test piece to ensure proper stitching quality.

2. How do you troubleshoot common problems encountered while operating a carpet sewing machine?

Tension issues:

- Adjust the upper and lower tension settings.

- Check for damaged or dull needles.

- Clean and oil the machine regularly.

Stitching quality issues:

- Select the correct needle and thread for the carpet material.

- Adjust the stitch length and width.

- Ensure the machine is properly calibrated.

Machine malfunctions:

- Check for loose connections or broken wires.

- Replace worn or damaged parts.

- Contact a qualified technician if necessary.

3. What are the safety precautions to be taken when using a carpet sewing machine?

- Always wear protective gear, including safety glasses and earplugs.

- Keep hands and loose clothing away from moving parts.

- Secure the carpet firmly to prevent it from slipping.

- Avoid prolonged use and take breaks to reduce fatigue.

- Maintain a clean and organized workspace.

- Follow the manufacturer’s instructions and guidelines.

4. How do you maintain a carpet sewing machine to ensure optimal performance?

- Clean the machine regularly, removing dust and debris.

- Oil and lubricate moving parts according to the manufacturer’s recommendations.

- Inspect and replace worn or damaged parts, such as needles, bobbins, and belts.

- Check the tension and calibration settings periodically.

- Store the machine in a dry and protected environment when not in use.

5. What are the different types of carpets you have experience sewing on?

- Loop pile carpets (e.g., Berber, Saxony)

- Cut pile carpets (e.g., plush, frieze)

- Commercial-grade carpets (e.g., nylon, polypropylene)

- Delicate carpets (e.g., silk, wool)

- Outdoor carpets (e.g., synthetic turf, rubber)

6. What is the best way to handle and store carpet rolls?

- Keep rolls upright in a dry and temperature-controlled environment.

- Avoid exposing rolls to direct sunlight or excessive moisture.

- Use protective covers or wrap rolls in plastic film to prevent damage.

- Store rolls on a flat surface or use a carpet rack for support.

7. How do you prepare a carpet for sewing?

- Inspect the carpet for any tears or damage.

- Clean the carpet to remove dirt and debris.

- Mark the cut lines and stitch areas accurately.

- Prepare the seam edges (e.g., serging, overcasting).

- Apply backing or underlay material if necessary.

8. What are the most common stitching techniques used in carpet sewing?

- Straight stitching (e.g., seams, edges)

- Overlock stitching (e.g., binding, finishing)

- Serging stitching (e.g., preventing fraying, adding decorative details)

- Pattern stitching (e.g., creating borders, embellishments)

- Blind stitching (e.g., invisible repairs, joining carpet pieces)

9. How do you measure and calculate carpet yardage accurately?

- Determine the length and width of the carpet area using a measuring tape.

- Multiply the length by the width to get the square footage.

- Add 10-15% for wastage and seam allowances.

- Consider the carpet pattern and orientation to minimize waste.

- Use a calculator or spreadsheet to ensure accuracy.

10. What is your experience in working with different types of carpet adhesives?

- Pressure-sensitive adhesives (PSA) for temporary bonding.

- Contact adhesives for strong, permanent bonds.

- Seam sealers for sealing seams and preventing unraveling.

- Carpet tape for securing edges and transitions.

- Underlay adhesives for adhering carpet to subfloors.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carpet Sewing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carpet Sewing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Carpet Sewing Machine Operators play a pivotal role in the manufacturing of carpets. Their responsibilities include:

1. Carpet Assembly

They are responsible for sewing together the backing material and face yarn, creating the primary structure of the carpet.

- Assembling the loom by setting up the warp beams, inserting the pile yarn, and adjusting the machine settings.

- Monitoring the weaving process and ensuring that the carpet is produced according to specifications.

2. Quality Control

Operators inspect the finished carpet for defects, such as missed stitches, uneven texture, or color inconsistencies.

- Identifying and repairing any defects in the carpet using specialized tools and techniques.

- Maintaining accurate records of carpet production and quality control checks.

3. Machine Maintenance

To ensure optimal performance and minimize downtime, operators perform basic maintenance tasks on the sewing machines.

- Lubricating and cleaning the machine parts regularly to prevent wear and tear.

- Troubleshooting minor issues and performing minor repairs to keep the machine running smoothly.

4. Health and Safety

Carpet Sewing Machine Operators are responsible for adhering to workplace safety regulations.

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Maintaining a clean and organized work area to prevent accidents or injuries.

Interview Tips

Preparing thoroughly for a Carpet Sewing Machine Operator interview can significantly increase your chances of success. Here are some tips:

1. Research the Company and Industry

Learn about the company’s history, values, and products. Research the carpet industry trends and major players.

- Visit the company website and read industry publications.

- Network with professionals in the field to gain insights and connections.

2. Practice Your Answers

Prepare for common interview questions by rehearsing your answers. Focus on highlighting your skills and experience.

- Use the STAR method to structure your answers: Situation, Task, Action, Result.

- Quantify your accomplishments using specific numbers and data.

3. Ask Informed Questions

Asking thoughtful questions during the interview demonstrates your interest and engagement.

- Inquire about the company’s production process, quality standards, or growth plans.

- Ask about opportunities for training and advancement.

4. Highlight Your Skills and Experience

Emphasize your ability to operate carpet sewing machines, perform quality control checks, and maintain equipment.

- Describe your experience with different types of carpet materials and machines.

- Share examples of your attention to detail and commitment to quality.

5. Be Enthusiastic and Motivated

Convey your passion for the role and your desire to contribute to the company’s success.

- Share your reasons for applying for the position and how it aligns with your career goals.

- Express your willingness to learn and grow within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Carpet Sewing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!