Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Carpet Yarn Winder Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Carpet Yarn Winder Operator so you can tailor your answers to impress potential employers.

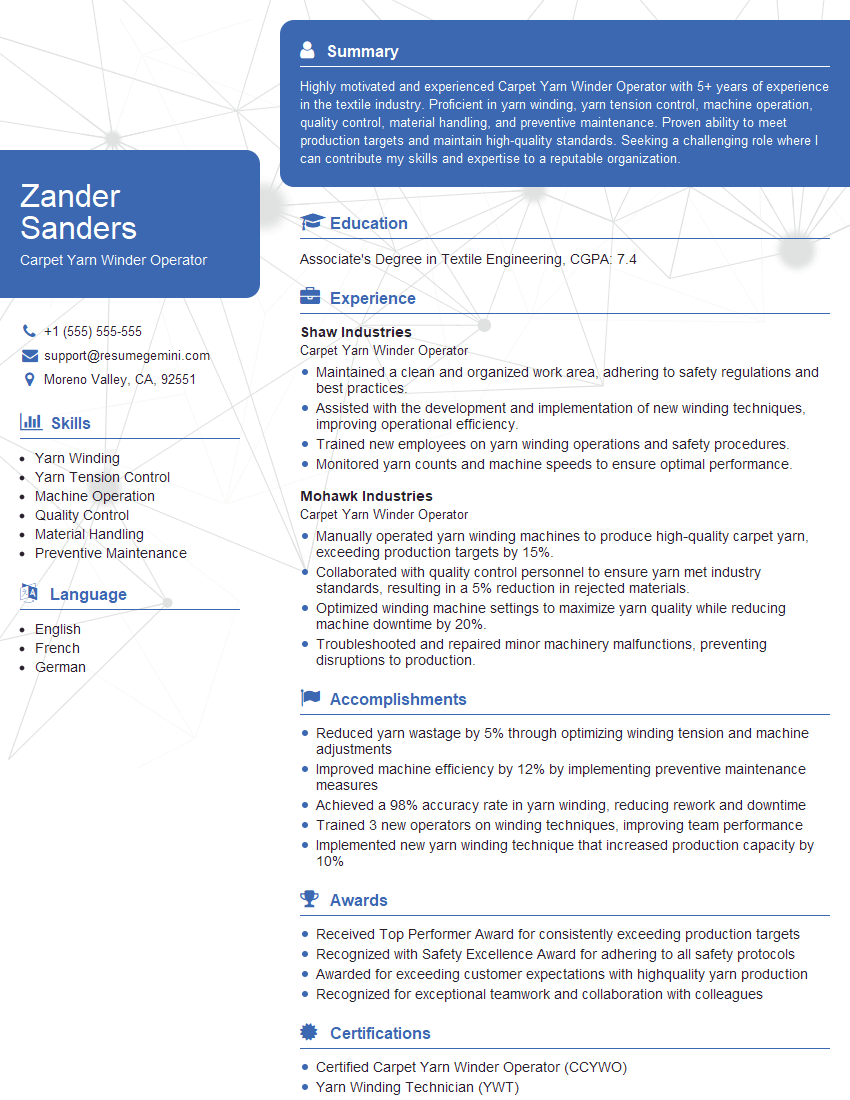

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carpet Yarn Winder Operator

1. Describe the steps involved in setting up a carpet yarn winder?

To set up a carpet yarn winder, I follow these steps:

- Prepare the machine by ensuring it is properly cleaned and lubricated.

- Load the yarn onto the creel or yarn rack.

- Thread the yarn through the machine’s tensioner and guides.

- Adjust the winding speed and tension settings based on the yarn specifications.

- Start the machine and monitor the winding process to ensure proper tension and yarn quality.

2. How do you ensure the wound yarn meets the required specifications?

Monitoring and Inspection

- Continuously monitor the winding process to identify any deviations in yarn tension or quality.

- Regularly inspect the wound yarn for defects such as uneven winding, knots, or breaks.

Calibration and Adjustments

- Calibrate the machine regularly to maintain accurate winding speed and tension.

- Make necessary adjustments to the machine settings based on the yarn specifications and winding requirements.

3. How do you handle yarn breaks during winding?

When a yarn break occurs during winding, I promptly take the following steps:

- Stop the machine immediately to prevent further damage to the yarn.

- Identify the location of the break and carefully remove the broken yarn from the machine.

- Retie the yarn ends together securely using the appropriate knotting technique.

- Restart the machine and monitor the winding process closely to ensure the yarn break does not reoccur.

4. What maintenance procedures are required for a carpet yarn winder?

To keep the carpet yarn winder in optimal condition, I perform the following maintenance procedures:

- Regularly clean the machine to remove any dust, debris, or yarn remnants.

- Lubricate all moving parts to ensure smooth operation and reduce wear and tear.

- Inspect the tensioner and guides for any damage or wear, and replace them as needed.

- Calibrate the machine at regular intervals to maintain accurate winding speed and tension.

5. How do you troubleshoot common problems encountered during carpet yarn winding?

To troubleshoot common problems during carpet yarn winding, I follow these steps:

- Identify the problem and observe the winding process to gather information.

- Refer to the machine’s manual or consult with experienced colleagues for guidance.

- Check for mechanical issues, such as loose belts, worn parts, or electrical faults.

- Adjust the machine settings, such as winding speed or tension, to optimize the winding process.

- Inspect the yarn for defects or inconsistencies that may be causing the problem.

6. What techniques do you use to improve the efficiency of carpet yarn winding?

I employ the following techniques to enhance the efficiency of carpet yarn winding:

- Proper machine setup and calibration to minimize yarn breaks and downtime.

- Regular maintenance and cleaning to ensure smooth operation and reduce the risk of problems.

- Optimization of winding speed and tension settings based on yarn specifications.

- Use of high-quality yarn to minimize the occurrence of yarn breaks and defects.

- Proper storage and handling of yarn to maintain its quality and prevent damage.

7. How do you ensure safety when operating a carpet yarn winder?

To ensure safety when operating a carpet yarn winder, I adhere to the following practices:

- Wear appropriate personal protective equipment, such as safety glasses and gloves.

- Keep the work area clean and organized to prevent tripping hazards or accidents.

- Never attempt to repair or adjust the machine while it is running.

- Follow lockout/tagout procedures when performing maintenance or repairs.

- Be aware of the moving parts of the machine and avoid contact with them.

8. What quality control measures do you implement to ensure the quality of the wound yarn?

To ensure the quality of the wound yarn, I implement the following quality control measures:

- Regularly inspect the wound yarn for defects, such as uneven winding, knots, or breaks.

- Use measuring tools to verify the yarn’s diameter, tension, and other specifications.

- Maintain records of winding parameters and yarn quality to monitor consistency and identify any potential issues.

- Compare the wound yarn to established quality standards and make adjustments to the winding process as needed.

- Provide feedback to the yarn supplier regarding any inconsistencies or quality concerns.

9. How do you prioritize your tasks and manage your time effectively?

To prioritize my tasks and manage my time effectively, I employ the following strategies:

- Create a daily or weekly task list and prioritize tasks based on their importance and urgency.

- Break down large tasks into smaller, manageable steps to make them less overwhelming.

- Delegate tasks to other team members when appropriate to distribute the workload.

- Use a time management tool or schedule to track my progress and stay on schedule.

- Take regular breaks throughout the day to maintain focus and productivity.

10. What are your career goals and how do you plan to achieve them?

My career goals are to:

- Advance my technical skills and knowledge in the field of carpet yarn winding.

- Contribute to the overall success and productivity of the team.

- Take on leadership responsibilities and mentor junior colleagues.

- Stay up-to-date with industry trends and best practices.

To achieve my goals, I plan to:

- Seek opportunities for training and development to enhance my skills.

- Actively participate in team projects and initiatives to demonstrate my abilities.

- Network with professionals in the industry and attend industry events.

- Set personal goals and track my progress to stay motivated and accountable.

- Embrace challenges as opportunities for growth and learning.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carpet Yarn Winder Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carpet Yarn Winder Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Carpet Yarn Winder Operator, you will be responsible for the following key tasks:

1. Operating Yarn Winding Machines

You will be operating yarn winding machines to produce high-quality yarn for carpet production.

- Setting up and calibrating yarn winding machines

- Loading yarn onto the machines and monitoring the winding process

- Ensuring yarn is wound evenly and consistently

- Identifying and rectifying any winding problems promptly

2. Maintaining Yarn Quality

You will be responsible for maintaining the quality of the yarn produced.

- Inspecting yarn for defects and imperfections

- Adjusting machine settings to minimize yarn breakage and ensure optimal yarn quality

- Maintaining a clean and organized work area

- Following established quality control procedures

3. Monitoring Production

You will be monitoring production to ensure efficiency and productivity.

- Tracking yarn production rates and identifying areas for improvement

- Reporting any production issues or delays to supervisors

- Maintaining accurate production records

- Assisting in the troubleshooting and resolution of production problems

4. Safety and Maintenance

You will be responsible for maintaining a safe and well-maintained work environment.

- Following all safety regulations and procedures

- Identifying and reporting any safety hazards

- Performing routine maintenance on yarn winding machines

- Keeping the work area clean and free of debris

Interview Tips

To help you ace the interview for a Carpet Yarn Winder Operator position, here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s website, industry, and specific job requirements. This will help you understand the company’s culture and demonstrate your interest in the role.

- Note down specific questions about the company and position to ask during the interview.

- Research common interview questions and prepare thoughtful answers that highlight your skills and experience.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating yarn winding machines and maintaining yarn quality. If possible, quantify your accomplishments with specific metrics. For example, you could mention that you “increased yarn production by 15% by optimizing machine settings.”

- Review the job description carefully and identify the keywords that match your skills and experience.

- Prepare examples of how your past experiences align with the requirements of the role.

3. Demonstrate Attention to Detail

Carpet Yarn Winder Operators must have a keen eye for detail. During the interview, highlight your ability to inspect yarn for defects and maintain a clean work area. You could also mention any experience you have with quality control procedures.

4. Emphasize Safety and Maintenance Knowledge

Safety and maintenance are crucial in the role of a Carpet Yarn Winder Operator. During the interview, emphasize your understanding of safety regulations and your ability to perform routine maintenance on yarn winding machines.

- Share any experience you have with identifying and reporting safety hazards.

- Explain how you prioritize safety in your work.

5. Prepare Questions to Ask

Preparing thoughtful questions to ask the interviewer demonstrates your interest and engagement. Some good questions to consider include:

- “Can you describe the typical day-to-day responsibilities of a Carpet Yarn Winder Operator in your company?”

- “What are the key performance indicators used to evaluate the success of Carpet Yarn Winder Operators?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Carpet Yarn Winder Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.