Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Carton Forming Machine Helper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

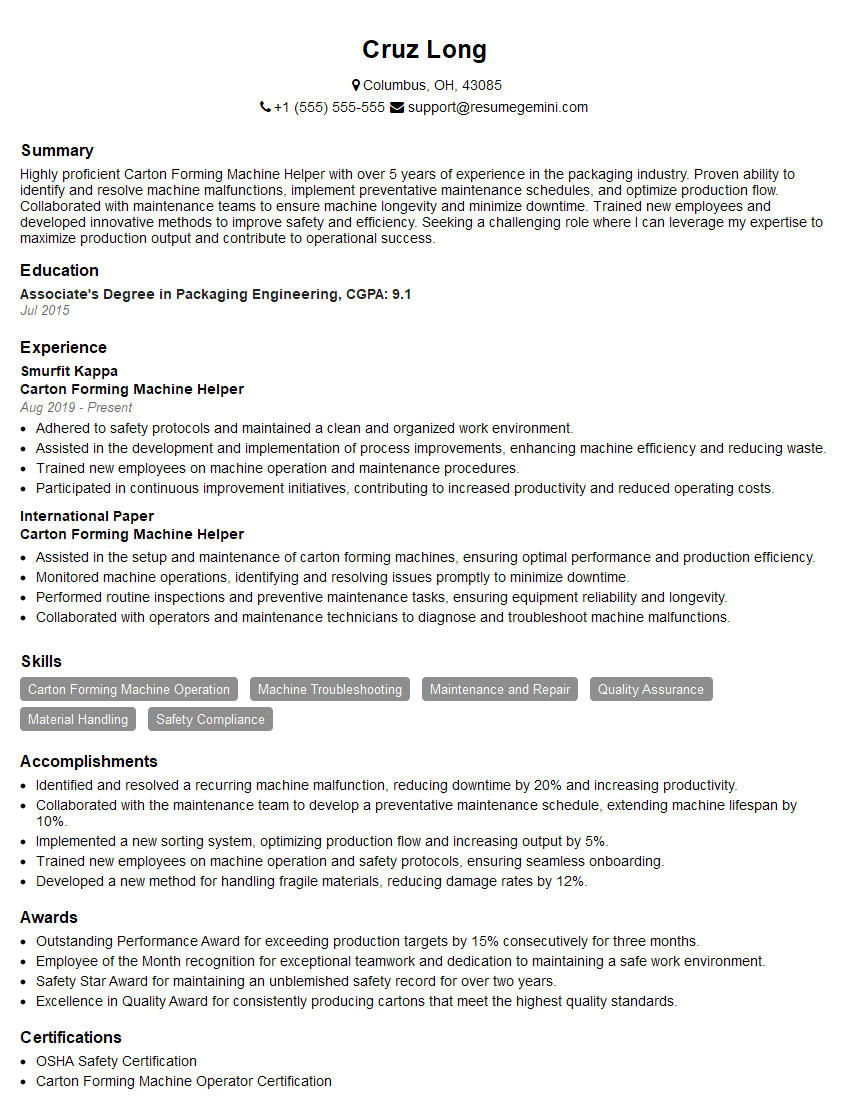

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Carton Forming Machine Helper

1. Explain the process of setting up a carton forming machine?

The process of setting up a carton forming machine involves the following steps:

- Loading the blanks: The first step is to load the flat carton blanks into the machine’s hopper.

- Adjusting the machine: The machine must be adjusted to accommodate the size and shape of the carton blanks being used.

- Setting up the gluing system: The gluing system must be set up to apply glue to the appropriate areas of the carton blanks.

- Testing the machine: Once the machine is set up, it should be tested to ensure that it is running properly.

2. What are the different types of carton forming machines?

Rotary die-cutter

- Uses a rotary die to cut and crease the carton blank.

- High-speed and high-volume production.

Flat-bed die-cutter

- Uses a flat die to cut and crease the carton blank.

- Slower speed and lower volume production than rotary die-cutters.

Folder-gluer

- Folds and glues the carton blank into a finished carton.

- Can be used in conjunction with a die-cutter or as a standalone machine.

3. How do you troubleshoot a carton forming machine that is not forming cartons correctly?

There are several potential causes for a carton forming machine that is not forming cartons correctly. Some common troubleshooting steps include:

- Checking the machine’s settings: Ensure that the machine is set up correctly for the size and shape of the carton blanks being used.

- Inspecting the carton blanks: Make sure that the carton blanks are free of defects and that they are being loaded into the machine correctly.

- Checking the gluing system: Verify that the gluing system is applying glue to the appropriate areas of the carton blanks.

- Inspecting the forming dies: Ensure that the forming dies are sharp and that they are properly aligned.

4. What are the safety precautions that must be taken when operating a carton forming machine?

When operating a carton forming machine, it is important to take the following safety precautions:

- Wear appropriate safety gear: This includes safety glasses, gloves, and earplugs.

- Keep hands away from moving parts: Never reach into the machine while it is running.

- Be aware of the machine’s surroundings: Make sure that there is enough space around the machine for safe operation.

- Follow all manufacturer instructions: Read and understand the manufacturer’s instructions for operating the machine.

5. How do you maintain a carton forming machine?

Regular maintenance is essential to keep a carton forming machine running smoothly and efficiently. Some common maintenance tasks include:

- Cleaning the machine: Remove any dust, debris, or glue buildup from the machine.

- Oiling and greasing moving parts: Lubricate all moving parts according to the manufacturer’s instructions.

- Inspecting the forming dies: Check the forming dies for wear and tear and replace them if necessary.

- Calibrating the machine: Regularly calibrate the machine to ensure that it is producing cartons to the correct specifications.

6. What are the different types of materials that can be used to make cartons?

Cartons can be made from a variety of materials, including:

- Paperboard: Paperboard is the most common material used to make cartons. It is strong, durable, and can be printed with a variety of designs.

- Corrugated cardboard: Corrugated cardboard is made from two layers of paperboard with a fluted layer in between. It is lightweight and strong, making it ideal for shipping products.

- Plastic: Plastic cartons are lightweight, durable, and can be molded into a variety of shapes. They are often used for packaging food and beverages.

7. What are the different types of closures that can be used for cartons?

There are several different types of closures that can be used for cartons, including:

- Tuck-end closure: A tuck-end closure is formed by tucking the flaps of the carton into each other.

- Lock-end closure: A lock-end closure is formed by interlocking the flaps of the carton.

- Adhesive closure: An adhesive closure is formed by applying glue to the flaps of the carton and pressing them together.

8. What are the different printing processes that can be used to decorate cartons?

There are several different printing processes that can be used to decorate cartons, including:

- Flexography: Flexography is a printing process that uses flexible rubber plates to transfer ink to the carton.

- Lithography: Lithography is a printing process that uses a flat printing plate to transfer ink to the carton.

- Digital printing: Digital printing is a printing process that uses a digital file to directly print the image onto the carton.

9. What are the different quality control procedures that are used to ensure the quality of cartons?

There are several different quality control procedures that are used to ensure the quality of cartons, including:

- Visual inspection: Visual inspection is used to check for defects such as tears, creases, or misprints.

- Dimensional inspection: Dimensional inspection is used to check for the correct size and shape of the cartons.

- Performance testing: Performance testing is used to check the strength and durability of the cartons.

10. What are the environmental considerations that should be taken into account when producing cartons?

When producing cartons, it is important to consider the environmental impact of the process. Some of the environmental considerations that should be taken into account include:

- Using recycled materials: Using recycled materials helps to reduce the environmental impact of carton production.

- Using sustainable forestry practices: Using sustainable forestry practices helps to ensure that the forests used to produce paperboard are managed in a sustainable way.

- Reducing waste: Reducing waste helps to reduce the environmental impact of carton production.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Carton Forming Machine Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Carton Forming Machine Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Operate the Carton Forming Machine

Assist in setting up, operating, and monitoring the carton forming machine to produce cartons of various sizes and styles.

- Load materials, such as cardboard blanks, into the machine.

- Adjust and maintain the machine’s settings to ensure optimal performance.

2. Monitor Production and Quality

Monitor the production process to identify and resolve any issues that may arise.

- Inspect cartons for quality defects and remove any non-conforming products.

- Maintain a clean and organized work area, ensuring adherence to safety protocols.

3. Perform Basic Maintenance

Perform basic maintenance and cleaning tasks to keep the machine in optimal condition.

- Lubricate moving parts, clean sensors and controls, and change filters as needed.

- Assist in troubleshooting and resolving minor machine malfunctions.

4. Follow Safety Procedures and Regulations

Adhere to all safety procedures and regulations to ensure a safe working environment.

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Follow proper lifting techniques and avoid operating machinery when fatigued.

Interview Tips

1. Research the Company and Position

Before the interview, take time to research the company and the specific role you are applying for. This will help you understand their industry, products, and culture, and tailor your answers accordingly.

2. Practice Answering Common Interview Questions

Prepare for common interview questions related to your skills, experience, and availability. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses and provide concrete examples.

3. Highlight Your Relevant Skills and Experience

Emphasize your abilities in operating machinery, following instructions, and maintaining a safe work environment. If you have previous experience with carton forming machines or similar equipment, be sure to mention it.

4. Show Enthusiasm and a Willingness to Learn

Express your enthusiasm for the role and the industry. Show that you are eager to learn and contribute to the team’s success. Be prepared to ask questions about the company’s operations and growth prospects.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive for your interview on time. Be polite and respectful to the interviewer and other staff you encounter.

Next Step:

Now that you’re armed with the knowledge of Carton Forming Machine Helper interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Carton Forming Machine Helper positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini