Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Case Finishing Machine Adjuster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

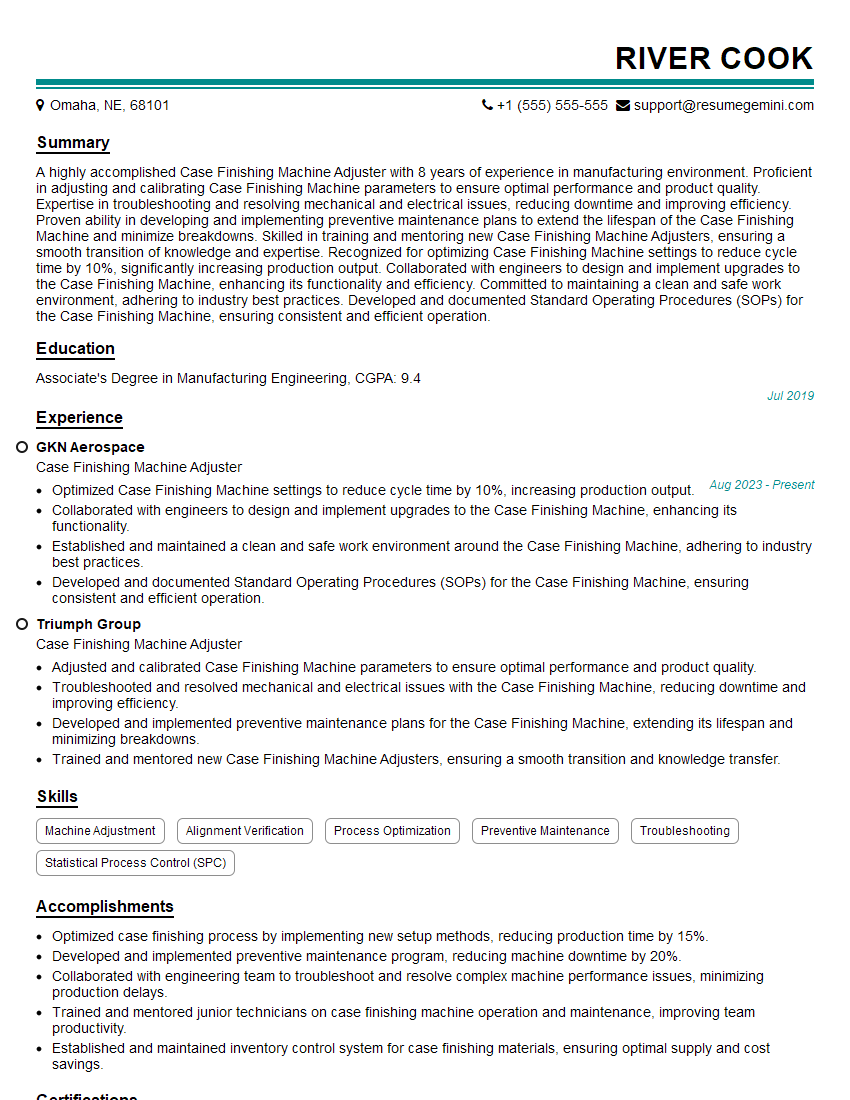

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Case Finishing Machine Adjuster

1. What are the key responsibilities of a Case Finishing Machine Adjuster?

- Operate and maintain case finishing machines to ensure efficient and quality production.

- Inspect finished cases for defects and adjust machine settings as necessary.

- Monitor machine performance and make adjustments to optimize productivity and minimize downtime.

- Troubleshoot and resolve machine issues, including mechanical and electrical problems.

- Maintain a clean and organized work area, ensuring compliance with safety regulations.

2. Describe the types of case finishing machines you have experience operating.

- Case tumbling machines with various abrasive media.

- Vibratory finishing machines for deburring and smoothing.

- Centrifugal finishing machines for polishing and descaling.

- Drag finishing machines for high-precision surface finishes.

3. How do you ensure that the case finishing process meets the specified requirements?

- Review process specifications and set machine parameters accordingly.

- Perform regular inspections of finished cases using gauges and other measuring tools.

- Monitor machine performance data and make adjustments to maintain consistent quality.

- Collaborate with production team to identify and address any deviations from specifications.

4. What are the common defects you encounter during the case finishing process?

- Scratches, dents, or burrs on case surfaces.

- Excessive roughness or unevenness.

- Insufficient polishing or descaling.

- Incorrect surface finish or color.

- Media contamination or embedded particles.

5. How do you troubleshoot and resolve machine malfunctions?

- Identify the symptoms and potential causes of the malfunction.

- Check electrical connections, mechanical components, and control systems.

- Use diagnostic tools and manuals to pinpoint the issue.

- Make necessary repairs or adjustments to restore machine functionality.

- Document the troubleshooting process and any corrective actions taken.

6. What steps do you take to ensure the safety and efficiency of the case finishing process?

- Follow established safety protocols and wear appropriate PPE.

- Inspect machines and work areas regularly for potential hazards.

- Maintain proper ventilation and dust collection systems.

- Optimize machine settings to minimize noise and vibration.

- Implement lean manufacturing principles to improve process efficiency and minimize waste.

7. How do you stay up-to-date with the latest advancements in case finishing technology?

- Attend industry conferences and webinars.

- Read technical articles and journals.

- Consult with equipment manufacturers and suppliers.

- Seek opportunities for training and professional development.

8. Describe your experience with implementing quality control measures in the case finishing process.

- Developed and implemented inspection procedures to ensure product quality.

- Established clear quality standards and specifications.

- Trained operators on proper inspection techniques.

- Analyzed inspection data to identify trends and areas for improvement.

- Collaborated with engineering team to enhance process design and equipment performance.

9. How do you handle high-volume production environments and tight deadlines?

- Prioritize tasks and effectively manage time.

- Optimize machine settings and reduce downtime.

- Work collaboratively with other team members to ensure smooth production flow.

- Implement lean manufacturing techniques to improve efficiency.

- Communicate effectively with supervisors and production managers.

10. What are your strengths as a Case Finishing Machine Adjuster?

- Strong technical knowledge and experience with case finishing machines.

- Excellent problem-solving and troubleshooting skills.

- Attention to detail and commitment to quality.

- Ability to work independently and as part of a team.

- Excellent communication and interpersonal skills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Case Finishing Machine Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Case Finishing Machine Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Case Finishing Machine Adjusters play a crucial role in the manufacturing process by ensuring that case finishing machines operate at optimal levels. Their responsibilities include but are not limited to:

1. Machine Operation and Maintenance

Adjusters are responsible for operating and maintaining case finishing machines to ensure proper functioning. This involves:

- Performing routine maintenance including cleaning, lubricating, and inspecting machines

- Identifying and troubleshooting machine malfunctions and making necessary repairs

- Calibrating and adjusting machines to meet specified requirements

2. Process Improvement

Adjusters are tasked with optimizing the case finishing process by:

- Monitoring machine performance and identifying areas for improvement

- Implementing process changes to increase efficiency and reduce waste

- Working with engineers and technicians to develop and implement new technologies

3. Quality Control

Adjusters are responsible for ensuring the quality of finished products by:

- Inspecting finished products for defects and non-conformities

- Making adjustments to machines and processes to meet quality standards

- Documenting quality control procedures and results

4. Training and Supervision

Adjusters may be responsible for training and supervising other machine operators, ensuring they follow proper procedures and maintain high-quality standards.

Interview Tips

Preparing thoroughly for a Case Finishing Machine Adjuster interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you’re applying for. This will help you understand the company’s culture, values, and the role’s responsibilities. You can find information on the company’s website, social media pages, and industry publications.

2. Practice Your Answers

Anticipate the common interview questions and practice your answers. Prepare examples that demonstrate your skills, experience, and knowledge in case finishing machine adjustment. Use the STAR method (Situation, Task, Action, Result) to structure your responses, providing specific examples of your accomplishments.

3. Highlight Your Technical Skills

Emphasize your technical skills and knowledge of case finishing machines. Discuss your experience with different types of machines and your ability to identify and resolve machine malfunctions. Quantify your accomplishments whenever possible to demonstrate your impact.

4. Show Your Commitment to Quality

Highlight your commitment to quality and attention to detail. Explain your processes for ensuring the quality of finished products and your experience with implementing quality control procedures.

5. Be Enthusiastic and Professional

During the interview, be enthusiastic and show genuine interest in the position. Maintain a professional demeanor, dress appropriately, and arrive on time for the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Case Finishing Machine Adjuster interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!