Feeling lost in a sea of interview questions? Landed that dream interview for Case Sealer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Case Sealer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

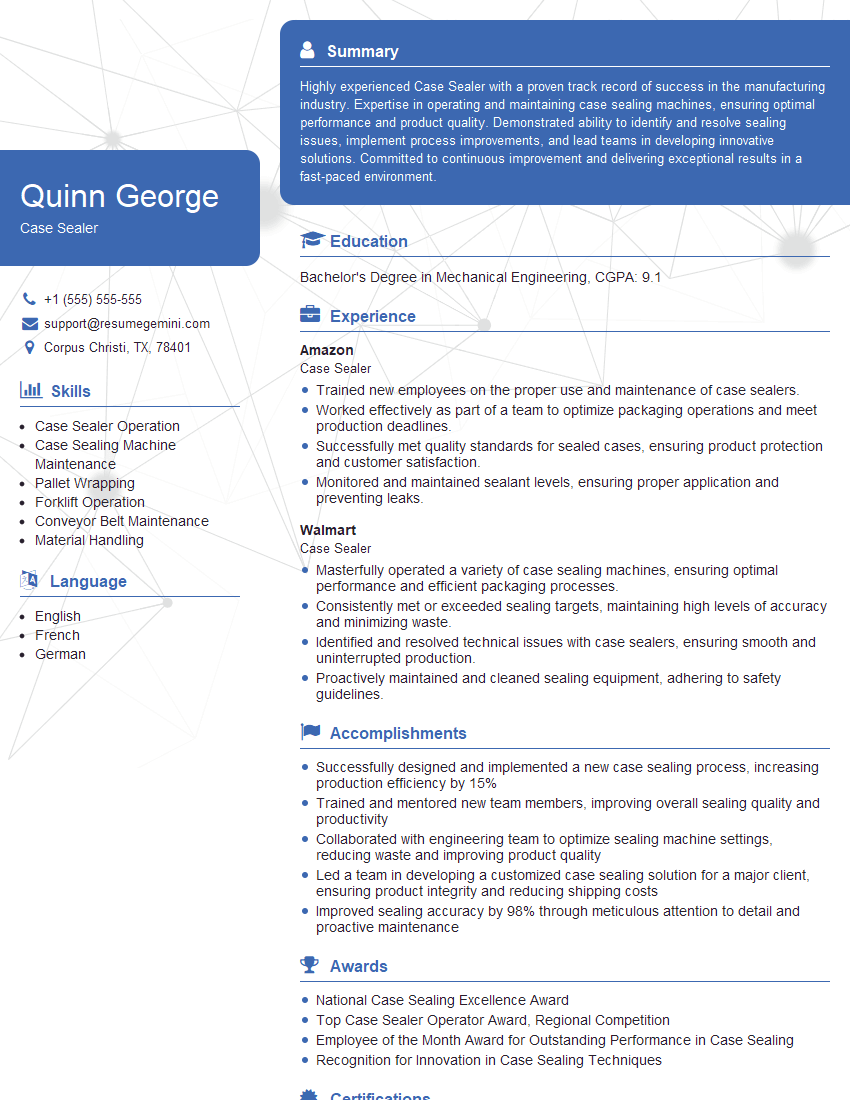

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Case Sealer

1. Could you elaborate on the different types of case sealers and their applications?

- There are various types of case sealers, each designed for specific applications:

- Top and bottom case sealers: Seal the top and bottom flaps of cases, commonly used for regular slotted containers (RSC).

- Side sealers: Seal the side flaps of cases, suitable for erecting and sealing RSCs.

- Wrap-around case sealers: Wrap film around the entire case, providing extra protection and stability.

- Random case sealers: Adapt to different case sizes and shapes, handling a wide range of products.

- Semi-automatic case sealers: Require manual case loading and sealing, offering flexibility for low-volume operations.

- Automatic case sealers: Fully automated, handling high volumes of cases efficiently.

2. What are the key factors to consider when selecting an appropriate case sealer for a specific application?

Understanding the Products and Packaging

- Product dimensions and weight

- Packaging material and design

- Case size and shape

Production Requirements

- Throughput speed and capacity

- Labor availability and skill level

- Space constraints

Integration with Existing Systems

- Conveyor systems

- Case erectors

- Labeling and coding equipment

3. Describe the process of adjusting a case sealer to accommodate different case sizes.

- Power down the case sealer for safety.

- Identify the adjustment points for the case length, width, and height.

- Use a tape measure or ruler to determine the required settings based on the case dimensions.

- Adjust the corresponding knobs or levers to match the measured dimensions.

- Manually test the adjusted settings by running a few cases through the sealer.

- Fine-tune the adjustments as needed to ensure proper sealing and case integrity.

4. How do you troubleshoot common issues that arise during case sealing operations?

- Case sealing issues:

- Poor seal quality: Check tape tension, clean sealing heads, replace worn parts.

- Case jamming: Verify proper case alignment, adjust conveyor speed, inspect for obstacles.

- Machine issues:

- Electrical problems: Check power supply, fuses, wiring, contact an electrician if necessary.

- Mechanical issues: Inspect belts, gears, bearings for wear or damage, lubricate as needed.

- Other issues:

- Incorrect case size: Adjust case sealer settings, verify case dimensions.

- Faulty or damaged tape: Replace the tape roll, check tape dispenser.

5. What maintenance procedures are necessary to ensure optimal performance of a case sealer?

- Regular cleaning:

- Wipe down exterior surfaces to remove dust and debris.

- Clean sealing heads and tape dispensers to prevent buildup.

- Lubrication:

- Lubricate moving parts according to manufacturer’s recommendations.

- Check oil levels and replace as necessary.

- Inspections:

- Inspect belts, chains, and gears for wear or damage.

- Check electrical connections and wiring.

- Calibration:

- Calibrate the case sealer regularly to ensure accurate sealing.

- Follow manufacturer’s instructions for calibration procedures.

6. How do you handle cases that are damaged or have irregular shapes?

- Damaged cases:

- Assess the extent of damage and determine if the case can be repaired.

- Use tape or strapping to reinforce damaged areas.

- Label the damaged case for special handling.

- Irregular shapes:

- Use specialized attachments or fixtures to accommodate irregular shapes.

- Manually seal cases that cannot be handled by the machine.

- Consider using custom-sized cases to reduce the need for manual handling.

7. What safety precautions should be taken when operating a case sealer?

- Wear appropriate safety gear, including gloves and safety glasses.

- Keep hands and fingers away from moving parts.

- Do not attempt to adjust or repair the machine while it is running.

- Lock out and tag out the machine before performing any maintenance.

- Ensure proper ventilation in the work area.

- Follow all manufacturer’s safety instructions.

8. How do you stay up-to-date with advancements in case sealing technology?

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Consult with equipment manufacturers and suppliers.

- Participate in online forums and discussion groups.

- Engage in ongoing training and certification programs.

9. What is your experience with integrating case sealers into automated packaging systems?

- Experience in interfacing case sealers with conveyors, case erectors, and other packaging equipment.

- Ability to configure and troubleshoot PLC controls and communication protocols.

- Understanding of data acquisition and analysis for performance optimization.

- Experience in implementing lean manufacturing principles to improve efficiency and reduce waste.

10. How do you handle high-volume packaging operations while maintaining accuracy and efficiency?

- Optimize machine settings and line speed to maximize throughput.

- Implement automated quality control systems to minimize errors.

- Train operators on proper sealing techniques and machine maintenance.

- Monitor production data to identify and address bottlenecks.

- Collaborate with other departments to ensure seamless integration and coordination.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Case Sealer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Case Sealer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Case Sealers are responsible for operating and maintaining case sealing machines that seal and close shipping cases, typically in manufacturing or distribution environments.

1. Operating Case Sealing Machines

Operate case sealing machines to seal and close corrugated boxes containing products.

- Adjust machine settings according to box size and material.

- Load boxes into the machine and monitor the sealing process.

2. Machine Maintenance

Perform routine maintenance and troubleshooting on case sealing machines.

- Clean and lubricate machine components.

- Identify and resolve minor mechanical issues.

3. Quality Control

Ensure the quality of sealed cases by inspecting them for proper sealing and integrity.

- Check seals for tightness and uniformity.

- Identify and reject cases with defects.

4. Safety Compliance

Follow established safety protocols and regulations when operating case sealing machines.

- Wear appropriate safety gear.

- Follow lockout/tagout procedures when performing maintenance.

Interview Preparation Tips

Thoroughly review the job description and identify the key responsibilities and requirements for the Case Sealer position.

1. Research the Company

Learn about the company’s history, products or services, and industry position. This will help you understand the context of the role and how it fits into the organization’s goals.

- Visit the company’s website.

- Read industry news and articles.

2. Highlight Relevant Experience

Emphasize your experience with operating case sealing machines or similar equipment in previous roles. Quantify your accomplishments with specific metrics whenever possible.

- Use action verbs and clear examples.

- Prepare specific examples of your problem-solving abilities and attention to detail.

3. Demonstrate Safety Knowledge

Discuss your understanding of safety protocols and regulations related to operating case sealing machines. Explain how you ensure safety in the workplace.

- Highlight your knowledge of lockout/tagout procedures.

- Describe your experience with hazard identification and risk assessment.

4. Be Prepared for Mechanical Questions

Anticipate questions about your knowledge of case sealing machine components and maintenance procedures. Review common maintenance tasks and troubleshooting techniques.

- Research different types of case sealing machines and their operation.

- Prepare answers to questions about lubrication, cleaning, and minor repairs.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Case Sealer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.