Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Casing Cooker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

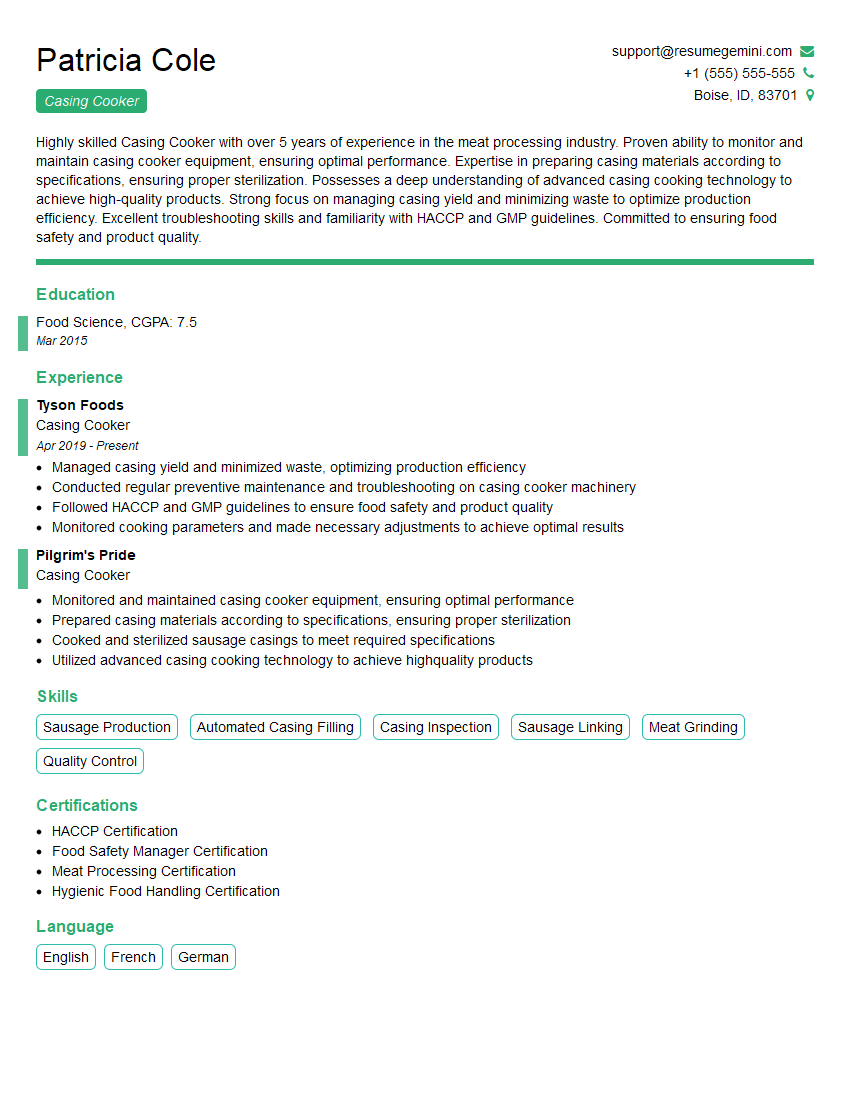

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casing Cooker

1. Explain the process of casing a sausage?

- Prepare the casing by soaking it in warm water to make it pliable

- Fill the casing with the sausage meat using a stuffer

- Twist or tie the casing at regular intervals to create individual sausages

- Smoke or cook the sausages according to the desired method

- Cool and store the sausages properly

2. What are the different types of sausage casings?

Natural casings

- Made from the intestines of animals, such as sheep, pigs, or cows

- Provides a traditional and authentic flavor

- Can be more expensive than artificial casings

Artificial casings

- Made from synthetic materials, such as collagen, cellulose, or plastic

- More consistent in size and shape

- Less expensive than natural casings

Edible casings

- Made from materials that can be consumed, such as seaweed or vegetable cellulose

- Provide a unique flavor and texture

- Can be more expensive than other types of casings

3. What are the factors to consider when choosing a sausage casing?

- Type of sausage being made

- Desired flavor and texture

- Budget

- Availability

- Equipment available

4. How do you ensure that the sausages are cooked evenly?

- Use a thermometer to check the internal temperature of the sausages

- Rotate the sausages regularly during cooking

- Cook the sausages over indirect heat

- Avoid overcrowding the pan or grill

5. What are the signs of overcooked sausage?

- Tough and dry texture

- Shrunken in size

- Darkened color

- Burnt or charred appearance

6. How do you prevent sausage from splitting during cooking?

- Use a sharp knife to score the casing

- Cook the sausages slowly over low heat

- Pierce the sausages with a toothpick or fork if they start to split

7. What are the different methods of smoking sausage?

- Hot smoking: Cooking the sausage at a temperature of 150-180 degrees Fahrenheit for several hours

- Cold smoking: Cooking the sausage at a temperature of 70-90 degrees Fahrenheit for several days or weeks

- Smoke roasting: Cooking the sausage in a smoker over indirect heat

8. How do you control the smoke flavor in sausage?

- Use different types of wood chips

- Vary the amount of smoke exposure

- Control the temperature of the smoker

9. What are the different types of sausage grinders?

- Manual grinders

- Electric grinders

- Commercial grinders

10. How do you maintain and clean a sausage grinder?

- Disassemble the grinder and clean the parts thoroughly

- Use warm water and a mild detergent

- Dry the parts completely before reassembling

- Oil the moving parts regularly

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casing Cooker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casing Cooker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Casing Cookers are responsible for operating and maintaining equipment used to cook and process casings for food products. They ensure that the casings meet the required specifications and are safe for use in food production.

1. Process Management

Monitor and control cooking parameters such as temperature, pressure, and cooking time.

- Ensure that casings are cooked to the appropriate degree of tenderness and texture.

- Make adjustments to cooking processes based on the type of casing and desired outcome.

2. Equipment Maintenance

Perform regular cleaning, maintenance, and calibration of cooking equipment.

- Clean and sanitize equipment to maintain hygiene and prevent contamination.

- Inspect and repair equipment as needed to ensure optimal performance.

3. Quality Assurance

Inspect casings for defects, discoloration, or other quality issues.

- Use sensory evaluation techniques to assess the quality of casings.

- Record and report any deviations from specifications to management.

4. Production Planning

Plan and schedule cooking operations to meet production targets.

- Estimate the required cooking time and resources based on production volume.

- Coordinate with other departments to ensure a smooth flow of materials.

5. Safety and Compliance

Comply with all safety regulations and guidelines relevant to casing cooking operations.

- Wear appropriate personal protective equipment (PPE).

- Adhere to sanitation and hygiene practices to prevent contamination.

Interview Tips

Preparing for a Casing Cooker interview requires a thorough understanding of the role’s responsibilities and the industry’s best practices.

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and market position.

- Research the food industry and trends related to casing production.

- Identify companies that the company partners with or competes against.

2. Practice Common Interview Questions

Anticipate typical interview questions and prepare thoughtful responses.

- Describe your experience in operating and maintaining casing cooking equipment.

- Explain how you ensure that casings meet the required specifications and quality standards.

3. Highlight Relevant Skills and Experience

Emphasize your technical skills, attention to detail, and commitment to food safety.

- Quantify your accomplishments and provide specific examples of successful outcomes.

- Describe your experience working in a fast-paced, production environment.

4. Demonstrate Safety Awareness

Show that you understand the importance of safety in a food processing facility.

- Discuss your experience following safety protocols and maintaining a clean and sanitary work area.

- Explain your understanding of the company’s safety policies and procedures.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Casing Cooker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.