Are you gearing up for a career in Casing Flusher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Casing Flusher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

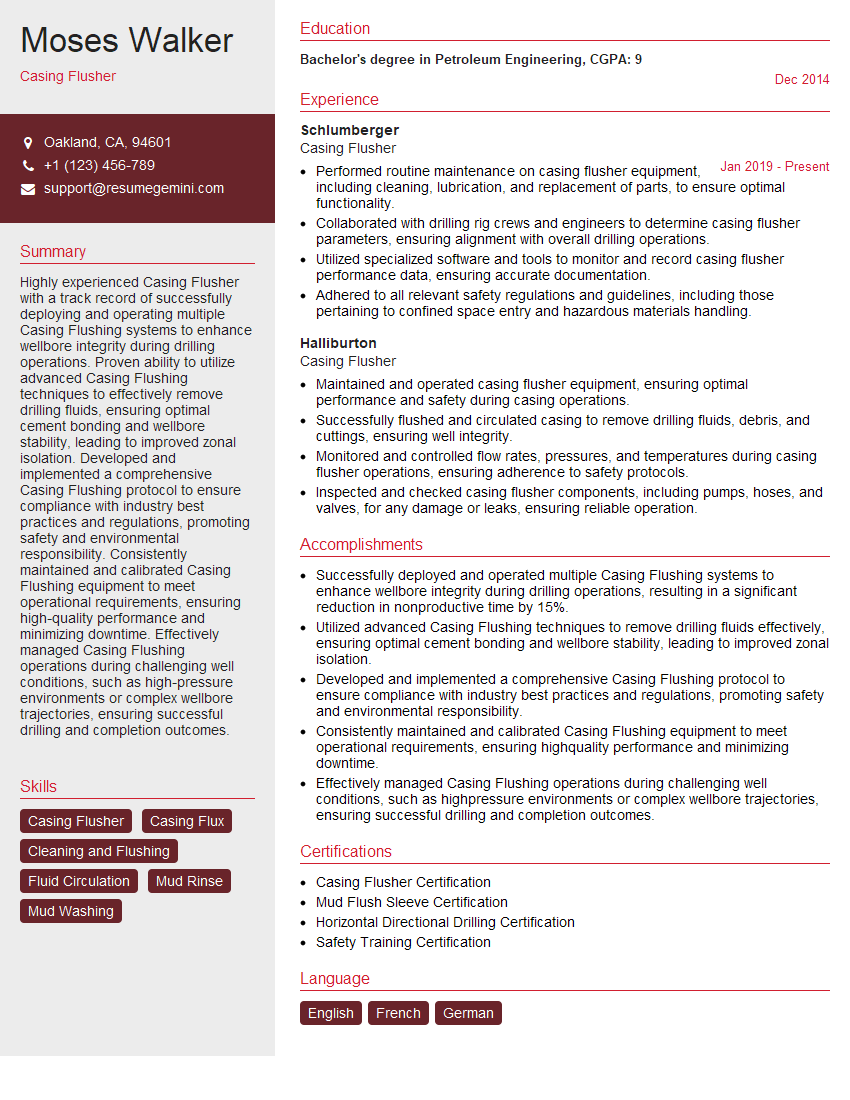

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casing Flusher

1. Explain the steps involved in casing flush?

The steps involved in casing flush are as follows:

- Establish circulation.

- Close the choke manifold and the wellhead valves.

- Open the casing fill-up line and the wellhead valves.

- Close the casing fill-up line and the wellhead valves.

- Open the choke manifold.

- Establish circulation.

2. What are the different types of casing flush?

Open casing flush

- In open casing flush, the casing is not sealed at the surface and the fluid is allowed to flow out of the casing into the wellbore.

Closed casing flush

- In closed casing flush, the casing is sealed at the surface and the fluid is pumped into the casing until it is full.

3. What is the purpose of a casing flush?

The purpose of a casing flush is to remove any debris or cuttings that may be present in the casing. This helps to prevent the casing from becoming damaged or blocked.

4. What are the risks associated with casing flush?

The risks associated with casing flush include:

- Damage to the casing

- Blockage of the casing

- Pressure surge

- Loss of circulation

5. What are the precautions that should be taken when performing a casing flush?

The precautions that should be taken when performing a casing flush include:

- Ensure that the casing is properly sealed at the surface.

- Use a low-pressure pump to pump the fluid into the casing.

- Monitor the pressure in the casing closely.

- Be prepared to stop the pump if there is any indication of a problem.

6. What are the different types of fluids that can be used for casing flush?

The different types of fluids that can be used for casing flush include:

- Water

- Oil

- Gas

- A combination of fluids

7. What is the best fluid to use for casing flush?

The best fluid to use for casing flush is a low-viscosity fluid that is compatible with the casing material. In most cases, water is the best choice.

8. What is the typical volume of fluid used for casing flush?

The typical volume of fluid used for casing flush is between 100 and 500 gallons.

9. What is the pressure range for casing flush?

The pressure range for casing flush is typically between 100 and 500 psi.

10. How long does it typically take to perform a casing flush?

It typically takes between 1 and 4 hours to perform a casing flush.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casing Flusher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casing Flusher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Casing flushers are responsible for operating and maintaining equipment used to clean and flush oil and gas well casings, tubing, and other equipment. They ensure that the equipment is operating properly and efficiently and that all safety protocols are followed.

1. Operate and Maintain Equipment

Casing flushers operate and maintain a variety of equipment, including:

- Pumps

- Compressors

- Separators

- Filters

2. Monitor Equipment Performance

Casing flushers monitor the performance of the equipment they are operating and make adjustments as necessary. They also inspect the equipment for any signs of damage or wear and tear.

3. Follow Safety Protocols

Casing flushers follow all safety protocols and procedures. They wear appropriate safety gear, such as hard hats, safety glasses, and gloves, and they operate equipment in accordance with all safety regulations.

4. Maintain a Clean and Organized Work Area

Casing flushers maintain a clean and organized work area. They clean up spills and debris, and they keep all equipment in its proper place.

Interview Tips

Preparing for an interview can be daunting, but there are some things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a Casing Flusher position:

1. Research the Company and the Position

Before you go on an interview, it’s important to do your research. Learn about the company you’re applying to, their history, their values, and their products or services. You should also research the specific position you’re applying for. What are the key responsibilities? What are the qualifications?

2. Practice Answering Common Interview Questions

There are some common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why do you want to work for this company?” It’s a good idea to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Example: Why do you want to work for this company?

- Answer: I’m impressed by your company’s commitment to safety and environmental protection. I’m also eager to learn more about your company’s innovative technologies and to contribute my skills and experience to your team.

3. Be Prepared to Talk About Your Experience and Skills

The interviewer will want to know about your experience and skills. Be prepared to talk about your relevant work experience, your education, and your training. You should also be able to articulate your strengths and weaknesses.

- Example: What are your strengths as a Casing Flusher?

- Answer: I’m a highly motivated and experienced Casing Flusher with a strong work ethic. I’m also a team player with excellent communication and interpersonal skills.

4. Dress Professionally and Arrive on Time

First impressions matter. Make sure you dress professionally for your interview and that you arrive on time. This will show the interviewer that you’re serious about the position and that you respect their time.

5. Be Yourself and Be Confident

The most important thing is to be yourself and be confident. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be confident in your abilities and in your potential to be a valuable asset to the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Casing Flusher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Casing Flusher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.