Are you gearing up for a career in Casing Inspector? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Casing Inspector and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

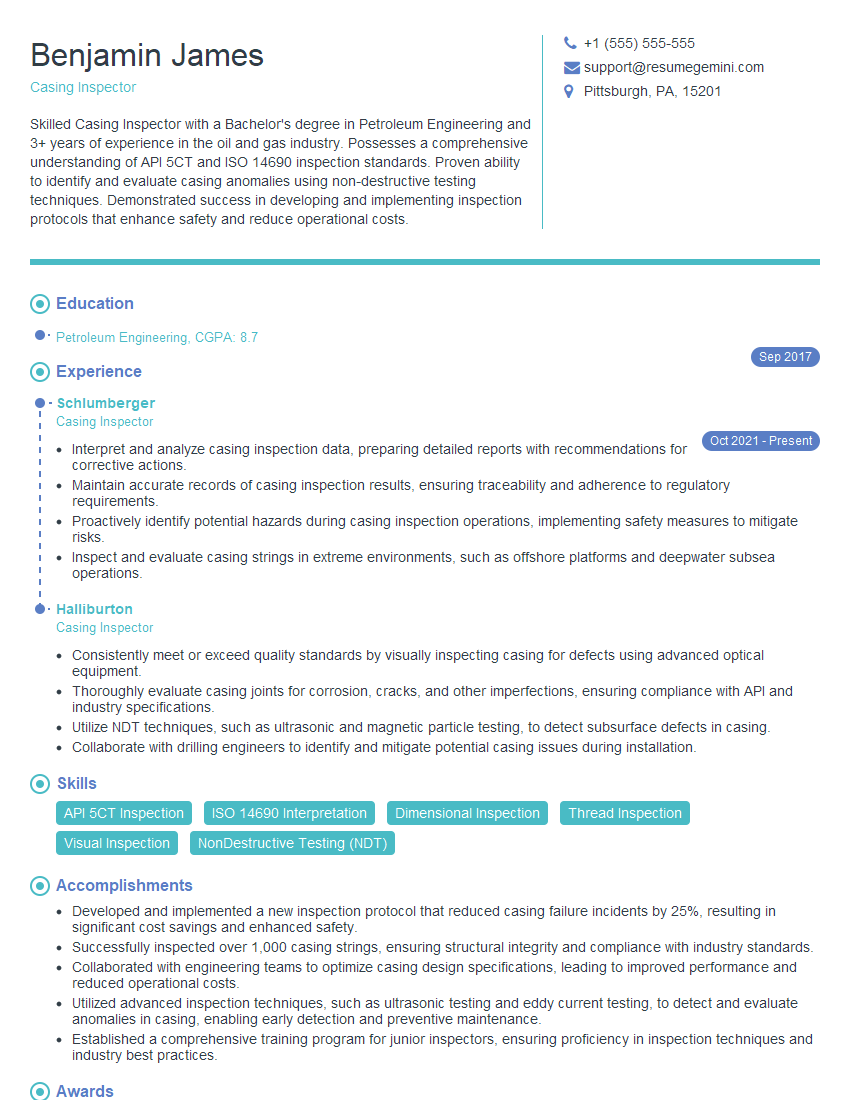

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casing Inspector

1. What are the different types of casing inspections and what are their purposes?

- Visual inspection: To identify surface defects, corrosion, and damage on the casing.

- Ultrasonic testing: To detect internal flaws, cracks, and delamination in the casing.

- Eddy current testing: To detect surface and near-surface flaws, such as cracks, pits, and corrosion.

- Magnetic particle testing: To detect surface and near-surface flaws, such as cracks and inclusions.

- Dye penetrant testing: To detect surface-breaking flaws, such as cracks and porosity.

- Radiographic testing: To detect internal flaws, such as cracks, voids, and inclusions.

2. What are the acceptance criteria for casing inspections?

API Standards

- API 5CT: Specification for Casing and Tubing for Oil and Gas Wells

- API RP 5C1: Recommended Practice for Ultrasonic Inspection of Casing and Tubing

- API RP 5C5: Recommended Practice for Magnetic Particle Inspection of Casing and Tubing

- API RP 5C7: Recommended Practice for Visual Inspection of Casing and Tubing

- API RP 5C8: Recommended Practice for Dye Penetrant Inspection of Casing and Tubing

- API RP 5C9: Recommended Practice for Radiographic Inspection of Casing and Tubing

Company Standards

- In-house inspection procedures and acceptance criteria.

3. What are the common defects found in casing inspections, and how do you evaluate their severity?

- Surface defects: Corrosion, pitting, dents, scratches

- Internal defects: Cracks, delamination, inclusions, voids

- Evaluation of severity:

- Size, location, orientation, and type of defect

- API and company standards

- Judgment and experience of the inspector

4. What are the different repair methods for casing defects, and how do you choose the appropriate method?

- Mechanical repair: Welding, grinding, patching

- Chemical repair: Epoxy injection, grouting

- Choice of method:

- Severity of the defect

- Location of the defect

- Cost and availability of repair methods

- API and company guidelines

5. What are the safety precautions that must be taken during casing inspections?

- Personal protective equipment (PPE): Hard hat, safety glasses, gloves

- Inspection equipment safety: Proper handling and calibration

- Work area hazards: Slippery surfaces, tripping hazards, electrical hazards

- Communication with crew members

- Following company safety protocols

6. What are the latest advancements in casing inspection technology?

- Automated ultrasonic inspection (AUT)

- Phased array ultrasonic testing (PAUT)

- Electromagnetic acoustic transducers (EMATs)

- Laser profilometry

- Data analysis and visualization software

7. How do you stay up-to-date with the latest developments in casing inspection techniques?

- Attending industry conferences and workshops

- Reading technical publications and research papers

- Participating in professional organizations

- Networking with other casing inspectors

- Seeking training and certification opportunities

8. What is the importance of maintaining accurate records of casing inspections?

- Legal and regulatory compliance

- Historical data for future inspections

- Identification of trends and patterns

- Decision-making and risk assessment

- Analysis and optimization of casing performance

9. How do you prioritize your workload and manage your time effectively?

- Using a to-do list or task manager

- Breaking down large tasks into smaller ones

- Estimating time for each task and setting deadlines

- Delegating tasks to others when possible

- Communicating with colleagues to ensure timely completion

- Regularly reviewing and adjusting priorities

10. What is your experience with using non-destructive testing (NDT) equipment?

- Ultrasonic testing (UT)

- Radiographic testing (RT)

- Eddy current testing (ET)

- Magnetic particle testing (MT)

- Dye penetrant testing (PT)

- Calibration, operation, and interpretation of NDT results

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casing Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casing Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Casing Inspectors are responsible for ensuring that casings meet the required specifications and standards. They inspect and test casings to identify defects and ensure that they are suitable for use. The key job responsibilities include:

1. Inspection and Testing

Conduct thorough inspections of casings to identify defects, such as cracks, dents, corrosion, and other imperfections.

- Use various inspection techniques, including visual inspection, ultrasonic testing, and magnetic particle testing.

- Test casings to ensure that they meet pressure, strength, and other performance requirements.

2. Quality Control

Maintain quality standards and ensure that casings meet the required specifications and regulations.

- Review and approve inspection reports and test results.

- Identify and report any deviations from specifications.

3. Recordkeeping and Documentation

Maintain accurate and detailed records of all inspections and tests.

- Generate inspection reports and summaries.

- Keep records of all inspection data, test results, and corrective actions.

4. Communication and Coordination

Communicate effectively with stakeholders, including supervisors, engineers, and customers.

- Provide feedback on inspection results and recommend corrective actions.

- Coordinate with other departments and external organizations to ensure compliance with regulations.

Interview Tips

To ace the interview for a Casing Inspector position, it is important to prepare thoroughly and showcase your skills and experiences. Here are some tips to help you prepare:

1. Research the Company and Role

Take time to learn about the company’s products, services, and industry. Understand the specific requirements of the Casing Inspector role and how your skills and experiences align with them

2. Practice Your Technical Skills

Review common inspection techniques and testing methods used in the industry. Practice answering technical questions related to casing inspection, such as:

- “Describe the process of ultrasonic testing and how it is used to detect defects in casings.”

- “Explain the importance of pressure testing and how it ensures the structural integrity of casings.”

3. Highlight Your Quality Assurance Experience

Emphasize your experience in maintaining quality standards and adherence to regulations. Provide examples of how you have identified and resolved quality issues in previous roles.

4. Showcase Your Communication and Interpersonal Skills

Casing Inspectors often interact with a wide range of stakeholders. Demonstrate your ability to communicate clearly and effectively, both verbally and in writing.

- “Describe a situation where you had to communicate inspection results to a client and ensure their satisfaction.”

- “Explain how you maintain effective relationships with colleagues and external organizations.”

5. Prepare Questions for the Interviewer

Preparing thoughtful questions for the interviewer demonstrates your engagement and interest in the role. Ask questions about the company’s safety policies, industry trends, or the specific projects that the team is working on.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Casing Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!