Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Casing Material Weigher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

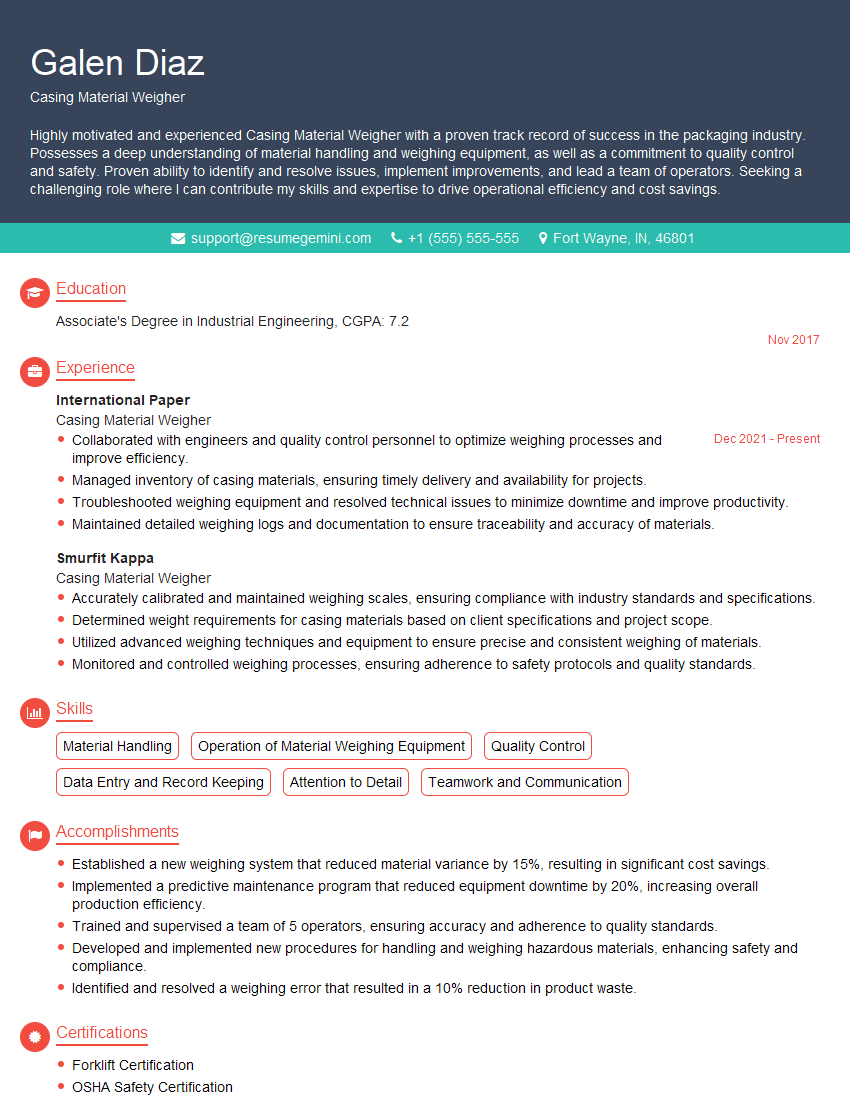

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casing Material Weigher

1. Explain the process of weighing casing materials.

The process of weighing casing materials involves several key steps:

- Preparation: Gather the necessary equipment, including a weigh scale, scoop or bucket, and protective gear.

- Tare the Scale: Zero out the scale to ensure accurate measurements.

- Load the Materials: Carefully load the casing materials onto the scale using the scoop or bucket.

- Record the Weight: Note down the weight displayed on the scale.

- Unload and Clean Up: Remove the materials from the scale and clean the equipment as per safety protocols.

2. What are the different types of weighing scales used for casing materials?

Mechanical Scales:

- Traditional beam balances with weights

- Spring scales with dials or indicators

Electronic Scales:

- Digital scales with LCD or LED displays

- Load cell scales with high precision

- Moisture analyzers for precise moisture content measurement

3. How do you ensure the accuracy of weighing results?

To ensure accurate weighing results, I follow several best practices:

- Proper Calibration: Regularly calibrate the scale to maintain its accuracy.

- Zeroing the Scale: Always tare the scale before each weighing to eliminate any external weight.

- Correct Loading: Handle the materials gently and avoid overloading or underloading the scale.

- Environmental Control: Minimize the effects of temperature, humidity, and vibrations on the weighing.

- Regular Maintenance: Perform routine scale maintenance and inspections to ensure optimal performance.

4. How do you troubleshoot common weighing issues?

When troubleshooting weighing issues, I systematically identify and address the potential causes:

- Inaccurate Readings: Verify scale calibration, check environmental factors, and inspect for damage.

- Unstable Readings: Examine the scale’s stability level, check for vibrations, and ensure proper loading.

- Power Issues: Check electrical connections, batteries, or power supply.

- Damaged Components: Inspect the scale’s load cell, display, or other components for any damage.

- Software Errors: If applicable, check for software updates or consult the manufacturer’s instructions.

5. What safety precautions are essential when weighing casing materials?

To ensure a safe work environment, I prioritize the following precautions:

- Proper Handling: Wear appropriate gloves and safety gear when handling casing materials.

- Stable Platform: Use the scale on a stable and level surface to prevent accidents.

- Avoid Overloading: Do not exceed the scale’s weight capacity to avoid damage or injuries.

- Electrical Safety: Ensure proper electrical connections and grounding to prevent electrical hazards.

- Emergency Procedures: Know the emergency procedures in case of any incidents or accidents.

6. How do you maintain and calibrate weighing scales?

To maintain and calibrate weighing scales effectively, I follow these steps:

- Regular Inspections: Conduct daily visual inspections to check for any damage or issues.

- Cleaning: Clean the scale regularly using appropriate cleaning agents to remove dust and debris.

- Calibration: Perform calibration at recommended intervals or as per manufacturer’s guidelines using certified weights.

- Calibration Logs: Maintain records of all calibration activities, including dates, weights used, and adjustment made.

- Training: Train personnel on proper scale maintenance and calibration procedures.

7. How do you handle discrepancies in weighing results?

When discrepancies in weighing results occur, I take the following steps to ensure accuracy:

- Re-Weigh: Repeat the weighing process to confirm the result.

- Check Scale Calibration: Verify that the scale is properly calibrated.

- Environmental Factors: Consider environmental conditions that may affect the weighing, such as temperature or humidity.

- Material Variability: Account for any variations in the casing materials, such as moisture content or density.

- Document Findings: Keep records of any discrepancies and actions taken to resolve them.

8. Describe your experience with different types of casing materials.

Throughout my career, I have worked with various types of casing materials, including:

- Steel Casing: Familiar with different grades and sizes of steel casing, including API J55 and N80.

- Composite Casing: Experience in handling composite casing systems that combine steel and non-metallic materials.

- Aluminum Casing: Knowledge of lightweight aluminum casing and its applications in specific scenarios.

- PVC Casing: Proficient in handling PVC casing, commonly used in water well drilling and other applications.

- Casing Accessories: Familiar with handling casing accessories, such as centralizers, scratchers, and float shoes.

9. Explain how you prioritize safety in the workplace.

Safety is paramount in my work; I adhere to the following principles:

- Hazard Identification: Identify potential hazards in the workplace and take steps to mitigate risks.

- PPE and Protective Gear: Utilize appropriate personal protective equipment and safety gear to minimize exposure to hazards.

- Safe Handling Practices: Follow established safe handling procedures for casing materials and equipment.

- Training and Communication: Participate in safety training programs and effectively communicate safety protocols to colleagues.

- Incident Reporting: Report any incidents or near-misses promptly to ensure timely investigation and corrective actions.

10. How do you stay updated on industry best practices and advancements in weighing technology?

To stay abreast of industry advancements, I follow these strategies:

- Professional Development: Attend conferences, workshops, and training programs related to weighing technology.

- Industry Publications: Read industry-specific journals and articles to gain insights into best practices and new developments.

- Manufacturer Updates: Stay informed about product updates and technological advancements from scale manufacturers.

- Networking: Engage with colleagues and industry peers to exchange knowledge and discuss emerging trends.

- Research and Innovation: Dedicate time to research and explore innovative weighing technologies and their applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casing Material Weigher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casing Material Weigher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Casing Material Weigher is responsible for ensuring the accuracy of the weight of casing materials used in the production of oil and gas wells. Key responsibilities include:

1. Weighing Casing Materials

Using specialized weighing equipment, the Casing Material Weigher accurately weighs casing materials, such as pipes, joints, and accessories, to ensure they meet the required specifications.

2. Maintaining Equipment

Regularly calibrating and maintaining weighing equipment to ensure its accuracy and precision is crucial for accurate weight measurements.

3. Recording and Reporting

Meticulously recording weight data and generating reports to document the weight of casing materials used in each well.

4. Quality Control

Inspecting casing materials for any defects or damage, rejecting those that do not meet quality standards.

Interview Tips

To ace the interview for a Casing Material Weigher position, candidates should:

1. Research the Company and Industry

Demonstrating knowledge of the company’s operations and the oil and gas industry shows interest and preparation.

2. Highlight Relevant Experience

Emphasize previous experience in weighing materials, particularly in the oil and gas sector. Quantify accomplishments with specific examples.

3. Showcase Attention to Detail

Explain how meticulousness and attention to detail ensure accurate weight measurements.

4. Communicate Effectively

Clearly and concisely convey information about weight measurements and any irregularities or concerns.

Next Step:

Now that you’re armed with the knowledge of Casing Material Weigher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Casing Material Weigher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini