Are you gearing up for an interview for a Casing Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Casing Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

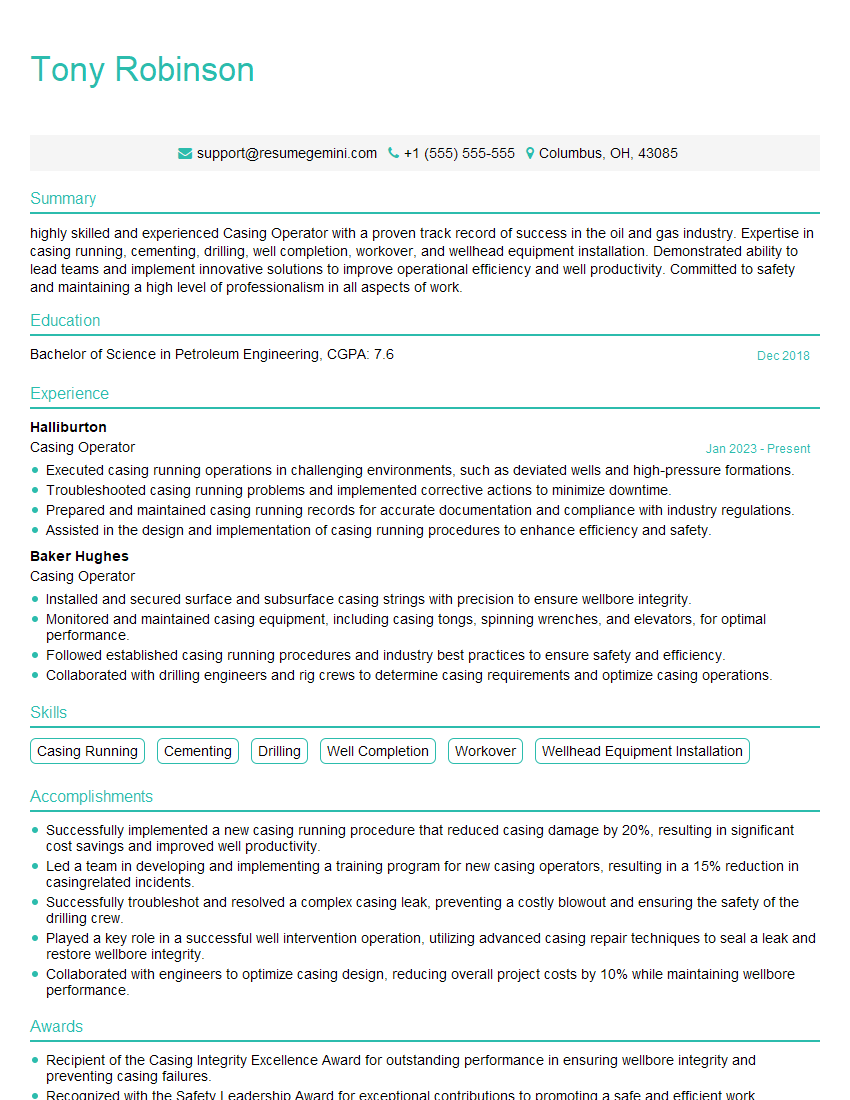

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casing Operator

1. What is the role of a casing operator?

As a Casing Operator, I would be responsible for operating and maintaining casing running equipment, ensuring proper installation and cementing of casing strings in oil and gas wells.

2. Describe the different types of casing and their applications?

Conductor Casing

- Installed first to protect the surface hole from collapse.

- Typically large in diameter and relatively short.

Surface Casing

- Protects against shallow formations and groundwater.

- Intermediate Casing

- Isolates high-pressure zones and prevents fluid migration.

Production Casing

- Provides structural support for the wellbore and protects the production zone.

- Typically the smallest diameter casing used.

3. What are the key responsibilities of a casing operator?

- Operate casing running equipment, including elevators, tongs, and power slips.

- Monitor casing running operations and ensure compliance with safety protocols.

- Inspect casing joints for defects and prepare them for running.

- Set and cement casing strings as per the drilling plan.

- Maintain and calibrate equipment used in casing operations.

4. What are the common challenges faced by casing operators?

- Ensuring proper handling and storage of casing to prevent damage.

- Dealing with high-pressure and hazardous environments during casing operations.

- Coordinating with other rig crew members to ensure smooth and efficient casing installation.

- Addressing potential downhole problems, such as stuck casing or hole instability.

5. What are the safety precautions that should be taken when working as a casing operator?

- Always wear appropriate personal protective equipment, including hard hat, gloves, and safety glasses.

- Follow established safety procedures and guidelines for casing operations.

- Inspect equipment regularly and report any defects or concerns.

- Communicate clearly with rig crew members to avoid accidents and ensure situational awareness.

6. What is the difference between casing cementing and casing running?

- Casing Running involves physically installing the casing strings into the wellbore.

- Casing Cementing follows casing running, where cement is pumped into the annulus between the casing and the wellbore to provide structural support and prevent fluid migration.

7. What is the importance of proper cementing in casing operations?

- Provides structural support for the casing string and prevents collapse.

- Seals the annulus between the casing and the wellbore, preventing fluid migration and potential blowouts.

- Protects the casing from corrosion and chemical attack.

- Ensures zonal isolation, preventing cross-flow between different formations.

8. Describe the different methods of casing cementing.

- Conventional Cementing: Cement is pumped through the casing and up the annulus, displacing drilling fluid.

- Reverse Cementing: Cement is pumped from the bottom of the well up through the annulus, displacing drilling fluid upward.

- Slurry Displacement Method: A pre-mixed cement slurry is used to displace drilling fluid in a continuous operation.

9. What are the factors that affect the success of casing cementing?

- Proper casing preparation and cleaning.

- Accurate mixing and placement of cement slurry.

- Adequate waiting time for cement to set and gain strength.

- Monitoring cementing operations to ensure proper displacement and zonal isolation.

10. What are the potential risks and complications associated with casing operations?

- Stuck casing due to hole instability or mechanical problems.

- Casing collapse due to excessive pressure or improper handling.

- Cementing problems, such as channeling or inadequate bonding.

- Fluid migration or blowouts due to poor zonal isolation.

- Wellbore damage due to improper casing installation or cementing procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casing Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casing Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Casing Operator

Casing Operators play a vital role in oil and gas industry, as they are responsible for the safe and efficient operation of casing equipment used in drilling wells. Their key responsibilities include:

1. Casing Equipment Operation

Operate and control casing equipment, such as casing strings, casing shoes, and casing hangers, to ensure proper installation and well completion.

- Install and remove casing strings.

- Position and secure casing hangers.

2. Equipment Maintenance and Inspection

Inspect and maintain casing equipment to ensure its functionality and prevent failures.

- Inspect casing strings for damage or leaks.

- Perform preventive maintenance on equipment.

3. Safety and Environmental Compliance

Adhere to safety regulations and environmental standards to ensure a safe and environmentally responsible worksite.

- Follow safety protocols during casing operations.

- Dispose of waste materials properly.

4. Monitoring and Communication

Monitor casing operations and communicate with team members to ensure coordination and timely problem-solving.

- Monitor pressure readings and other parameters.

- Communicate with drillers and engineers.

Interview preparation tips for Casing Operator

To ace your Casing Operator interview, consider these preparation tips:

1. Research the company and role

Familiarize yourself with the company’s operations, values, and the specific responsibilities of the Casing Operator role.

- Visit the company’s website.

- Review industry publications.

2. Highlight your skills and experience

Emphasize your technical skills, experience in casing operations, and your commitment to safety and environmental compliance.

- Quantify your achievements using specific metrics.

- Prepare examples of your problem-solving abilities.

3. Practice answering common interview questions

Prepare for common interview questions related to your skills, experience, and the industry. Practice answering these questions clearly and concisely.

- Prepare for questions about your knowledge of casing equipment.

- Practice describing your safety procedures.

4. Dress professionally and arrive on time

Dress appropriately for the interview and arrive on time to show your professionalism and respect for the interviewer’s time.

- Wear business formal attire.

- Arrive at the interview location 15 minutes early.

5. Ask thoughtful questions

Prepare thoughtful questions to ask the interviewer about the company, the role, and the industry. This shows your interest and engagement.

- Ask about the company’s safety record.

- Inquire about opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Casing Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!