Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Casing Puller position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

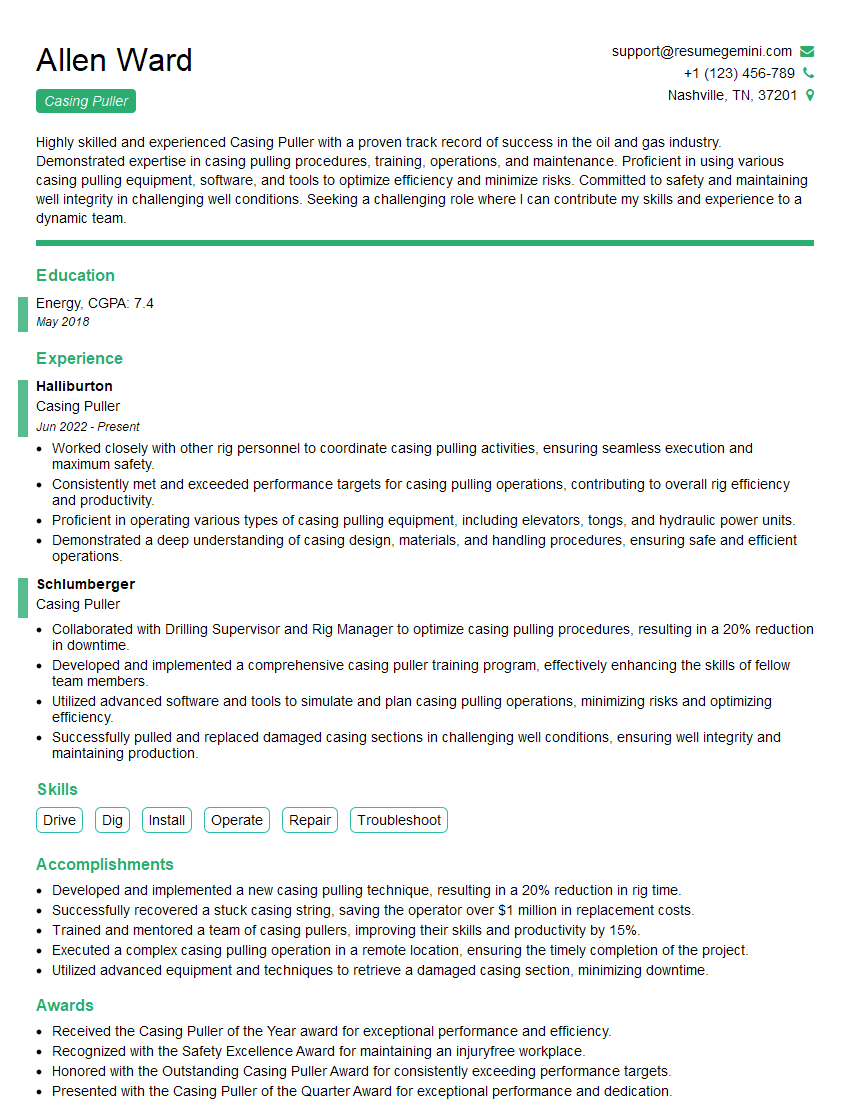

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casing Puller

1. Explain the steps involved in casing pulling operation?

The steps involved in casing pulling operation are as follows:

- Preparation: This includes gathering the necessary tools and equipment, such as casing pullers, elevators, and tongs, as well as preparing the wellsite and ensuring that the rig is in good working order.

- Cutting the casing: The casing is cut using a hydraulic or mechanical casing cutter at a predetermined depth.

- Installing the casing puller: The casing puller is installed on the casing string above the cut section.

- Pulling the casing: The casing is pulled out of the well using the casing puller. This is done by applying hydraulic pressure to the casing puller, which grips the casing and pulls it upward.

- Laying down the casing: The casing is laid down in a designated area on the rig floor or on a pipe rack.

- Inspection and maintenance: The casing is inspected for any damage or defects. Any necessary repairs or maintenance are performed before the casing is reused or disposed of.

2. What are the different types of casing pullers and how do they work?

There are two main types of casing pullers: hydraulic casing pullers and mechanical casing pullers.

Hydraulic Casing Pullers

- Hydraulic casing pullers use hydraulic pressure to grip and pull the casing. They are typically used for pulling large diameter casing strings.

- Hydraulic casing pullers consist of a hydraulic cylinder, a piston, and a set of slips. The hydraulic cylinder provides the force to pull the casing, while the piston and slips grip the casing.

Mechanical Casing Pullers

- Mechanical casing pullers use a mechanical mechanism to grip and pull the casing. They are typically used for pulling smaller diameter casing strings.

- Mechanical casing pullers consist of a set of jaws that grip the casing and a set of gears that provide the force to pull the casing.

3. What are the safety precautions that must be taken when pulling casing?

The following safety precautions must be taken when pulling casing:

- Ensure that the well is properly controlled and that there is no pressure in the casing string.

- Wear appropriate personal protective equipment, such as hard hats, safety glasses, and gloves.

- Use proper lifting and rigging techniques when handling casing and other equipment.

- Be aware of the potential hazards of working around heavy equipment and rotating machinery.

- Follow all company safety procedures and guidelines.

4. What are the common problems that can occur during casing pulling operations and how can they be prevented?

Some common problems that can occur during casing pulling operations include:

- Casing getting stuck: This can be caused by a variety of factors, such as corrosion, scale buildup, or formation collapse. To prevent this, the casing should be inspected regularly and any potential problems should be addressed promptly.

- Casing damage: This can occur if the casing is pulled too quickly or if it is subjected to excessive force. To prevent this, the casing should be pulled slowly and carefully, and the proper equipment should be used.

- Equipment failure: This can occur if the equipment is not properly maintained or if it is overloaded. To prevent this, the equipment should be inspected regularly and any necessary maintenance should be performed.

5. What are the different types of casing handling tools and how are they used?

There are a variety of casing handling tools used in casing pulling operations, including:

- Casing elevators: These are used to lift and lower casing strings.

- Casing tongs: These are used to make up and break out casing joints.

- Casing slips: These are used to hold casing strings in place while they are being worked on.

- Casing bowls: These are used to support casing strings while they are being pulled.

- Casing spiders: These are used to hold casing strings in place while they are being run into or pulled out of the well.

6. What are the different types of casing running methods and when are they used?

The different types of casing running methods are:

- Conventional casing running: This is the most common method of running casing, and involves using a casing elevator to lift the casing string into the wellbore.

- Float casing running: This method is used when the casing string is not long enough to reach the bottom of the wellbore. In this method, the casing string is floated into the wellbore using a drilling fluid.

- Rotation casing running: This method is used when the casing string is being run into a directional wellbore. In this method, the casing string is rotated as it is run into the wellbore.

7. What are the different types of casing connections and how are they made up?

The different types of casing connections are:

- Threaded connections: These connections are made by threading the casing joints together.

- Welded connections: These connections are made by welding the casing joints together.

- Coupled connections: These connections are made by using a coupling to connect the casing joints together.

8. What are the different types of casing accessories and when are they used?

The different types of casing accessories are:

- Casing centralizers: These are used to center the casing string in the wellbore.

- Casing shoes: These are used to protect the bottom of the casing string from damage.

- Casing collars: These are used to connect different sections of casing string together.

- Casing packers: These are used to isolate different sections of the wellbore.

9. What are the different types of casing inspection methods and when are they used?

The different types of casing inspection methods are:

- Visual inspection: This is the most basic type of casing inspection, and involves visually inspecting the casing for any signs of damage.

- Ultrasonic testing: This method uses ultrasonic waves to inspect the casing for any defects.

- Radiographic testing: This method uses X-rays to inspect the casing for any defects.

10. What is the importance of casing maintenance and how can it be ensured?

Casing maintenance is important to ensure the integrity of the wellbore and to prevent any potential problems. Casing maintenance can be ensured by:

- Regularly inspecting the casing for any signs of damage.

- Performing any necessary repairs or maintenance promptly.

- Following all company safety procedures and guidelines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casing Puller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casing Puller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Casing Puller plays a crucial role in maintaining safe and efficient drilling operations, ensuring the integrity of the wellbore. Key job responsibilities include:1. Casing Recovery and Handling

Effectively plan and safely execute casing recovery operations.

- Operate and maintain casing pulling equipment, including elevators, tongs, and hydraulic units.

- Control and monitor the pulling of casing strings to minimize damage and ensure wellbore stability.

2. Wellbore Maintenance and Monitoring

Monitor the condition of the wellbore and casing during pulling operations.

- Identify potential wellbore damage and take appropriate corrective measures.

- Collaborate with other team members to ensure smooth recovery and mitigate risks.

3. Safety and Compliance

Adhere to all safety protocols and regulations related to casing recovery operations.

- Utilize proper personal protective equipment (PPE) and follow established safety guidelines.

- Report any potential hazards or concerns to the rig supervisor promptly.

4. Equipment Inspection and Maintenance

Regularly inspect and maintain casing pulling equipment to ensure optimal performance.

- Identify worn or damaged components and coordinate repairs promptly.

- Maintain a clean and organized work area to enhance efficiency and safety.

Interview Tips

To ace the interview for the Casing Puller position, candidates should prepare thoroughly and demonstrate their knowledge and skills. Here are some helpful tips:1. Research the Company and Industry

Familiarize yourself with the company’s operations, culture, and safety record.

- Research the latest industry trends and advancements in casing recovery technologies.

- Review relevant safety guidelines and regulations to demonstrate your understanding of industry best practices.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating casing pulling equipment and handling casing strings.

- Provide specific examples of successful casing recovery operations you have been involved in.

- Quantify your accomplishments and outcomes whenever possible to demonstrate your impact.

3. Showcase Your Safety Mindset

Consistently emphasize your commitment to safety and your adherence to established protocols.

- Describe your experience in identifying and mitigating potential wellbore hazards.

- Explain your approach to maintaining a clean and safe work environment.

4. Demonstrate Teamwork and Communication Skills

Highlight your ability to work effectively with a team and communicate clearly.

- Provide examples of how you have successfully collaborated with other team members to achieve project goals.

- Emphasize your ability to listen attentively, communicate effectively, and resolve conflicts amicably.

5. Prepare for Common Interview Questions

Anticipate and prepare for common interview questions related to casing pulling operations.

- Explain the steps involved in planning and executing a casing recovery operation.

- Describe the potential hazards associated with casing recovery and how to mitigate them.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Casing Puller interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!