Are you gearing up for an interview for a Casing Running Machine Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Casing Running Machine Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

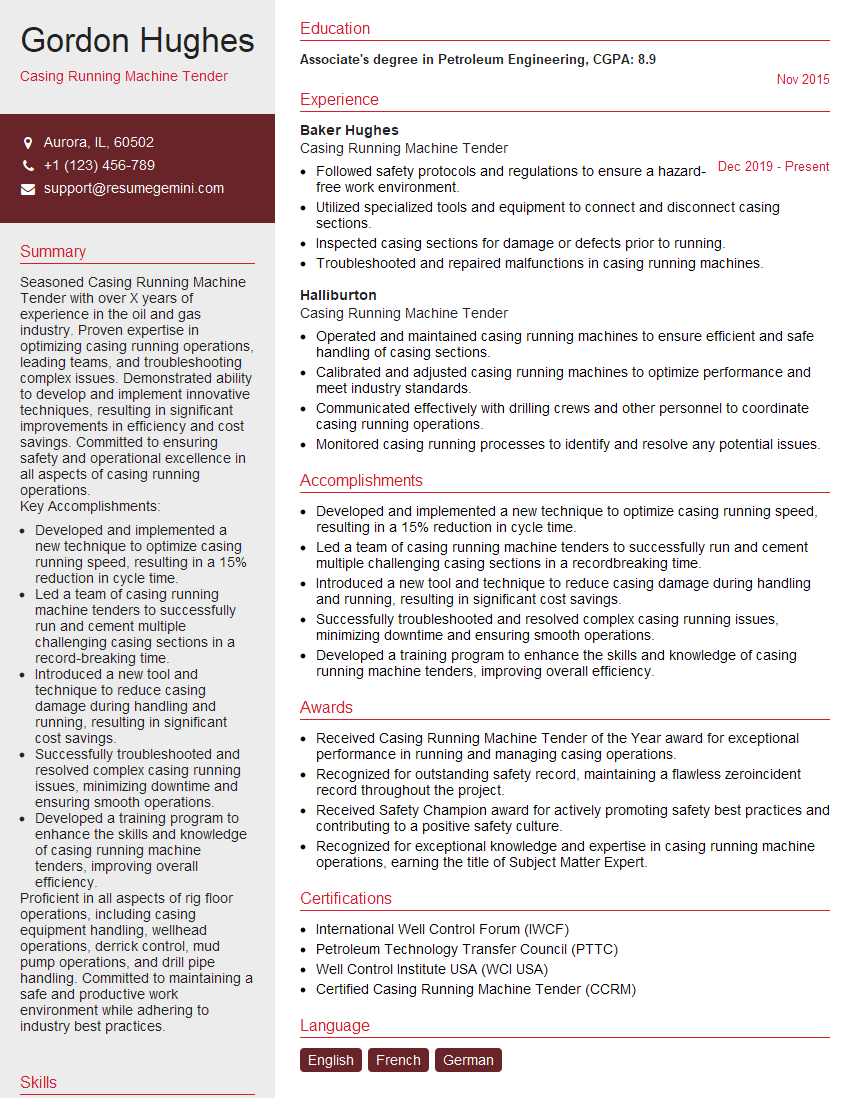

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casing Running Machine Tender

1. Explain the different types of casing running machines and their applications?

- Conventional Casing Running Machine: Used to run casing in vertical wells, features a rotating table, and slips to hold the casing in place

- Mechanized Casing Running Machine: Automated system that handles casing handling, stabbing, and running operations, increasing efficiency

- Casing Pusher: Pushes casing into the wellbore using hydraulic pressure, suitable for horizontal wells where conventional methods are challenging

- Continuous Casing Running Machine: Continuously feeds casing into the wellbore without stopping, minimizing connection time and Risiken

2. Describe the operational procedure for running casing using a casing running machine?

General Procedure

- Prepare the machine and ensure it’s properly aligned with the wellhead

- Install the casing slips and ensure they are securely tightened

- Stab the casing into the wellhead and connect it to the machine

- Initiate casing running by controlling the speed and torque of the machine

- Monitor the operation and make adjustments as needed to prevent bending or damage to the casing

Specific Considerations

- Adjusting running speed according to casing size, well depth, and formation conditions

- Monitoring hydraulic pressure to ensure proper lubrication and prevent stuck casing

- Maintaining proper torque to prevent thread damage or casing overtightening

3. What are the safety precautions you take when operating a casing running machine?

- Wear appropriate safety gear (hard hat, gloves, etc.)

- Ensure proper machine setup and alignment before operation

- Keep hands and body away from moving parts and pinch points

- Maintain a safe distance from the wellhead and casing

- Communicate clearly with colleagues and follow hand signals

- Monitor operational parameters (pressure, torque, speed) and adjust as needed

- Immediately stop operation if any unsafe condition or equipment malfunction is detected

4. How do you troubleshoot common problems encountered while running casing?

- Stuck Casing: Check lubrication, apply pressure, or use mechanical tools (e.g., jars, slips)

- Excessive Torque: Reduce running speed, check thread condition, or adjust machine settings

- Hydraulic Leaks: Locate and tighten fittings, check hoses, or replace seals

- Machine Malfunctions: Troubleshoot electrical or mechanical issues, consult manufacturer’s guidelines

- Casing Damage: Inspect casing for bends, breaks, or other defects, consult with drilling team for corrective actions

5. What are the essential maintenance tasks to ensure the optimal performance of a casing running machine?

- Regular lubrication of moving parts (e.g., gears, bearings, chains)

- Inspection and tightening of bolts and connections

- Testing of hydraulic systems and pressure relief valves

- Electrical inspections and grounding checks

- Cleaning and greasing of exposed surfaces to prevent corrosion

- Following manufacturer’s recommended maintenance schedule

6. How do you coordinate with the drilling team to ensure a successful casing running operation?

- Review casing running plan and discuss specific requirements

- Communicate casing depth, connection points, and running speed

- Collaborate on troubleshooting and contingency plans in case of unexpected issues

- Provide updates on casing running progress and any deviations from the plan

- Listen to the drilling team’s feedback and adjust operations accordingly

7. What are the key performance indicators (KPIs) you monitor to evaluate the efficiency of casing running operations?

- Casing running time (total and per joint)

- Connection time (make up and break out)

- Number of stuck casing incidents

- Casing integrity (damage or leaks)

- Machine uptime and maintenance costs

8. How do you keep up with the latest advancements and best practices in casing running technology?

- Attend industry conferences and workshops

- Review technical publications and articles

- Consult with equipment manufacturers and service providers

- Seek feedback and exchange knowledge with experienced colleagues

- Stay informed about new technologies and their potential applications

9. What is your understanding of the role of torque monitoring during casing running?

- Monitoring torque helps ensure proper thread engagement and prevents overtightening or undertightening

- Excessive torque can lead to thread damage or casing deformation

- Insufficient torque can result in loose connections or leaks

- By monitoring torque, the operator can adjust running speed or torque settings to achieve optimal thread makeup

10. Explain the importance of proper handling and storage of casing to prevent damage or premature wear.

- Proper handling techniques minimize scratches, dents, or bends that could affect casing integrity

- Storage in designated areas prevents exposure to weather elements (e.g., rust, corrosion)

- Using racks or cradles supports casing and prevents deformation

- Protecting casing ends with caps prevents damage or contamination

- Following manufacturer’s guidelines ensures longevity and optimal performance of casing

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casing Running Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casing Running Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Casing Running Machine Tenders operate and maintain equipment used to run casing into oil and gas wells. They work closely with other members of the drilling crew, including the driller, mud engineer, and geologist, to ensure that the casing is run safely and efficiently.

1. Daily Tasks

Their daily tasks may include:

- Inspecting and maintaining casing running equipment

- Preparing the casing for running, including cleaning and lubricating

- Running the casing into the well, using a variety of techniques

- Cementing the casing in place, using a variety of techniques

- Troubleshooting and resolving any problems that may occur during the casing running process

2. Safety Regulations and Procedures

In addition to their daily tasks, Casing Running Machine Tenders must also:

- Follow all safety regulations and procedures

- Work as part of a team

- Be able to work independently

- Be physically fit and able to work long hours in a variety of conditions

3. Working Conditions

Casing Running Machine Tenders typically work outdoors in a variety of weather conditions. They may also be required to work in confined spaces.

4. Career Prospects

With experience, Casing Running Machine Tenders can advance to positions such as Driller, Tool Pusher, or Superintendent.

Interview Tips

To ace an interview for a Casing Running Machine Tender position, candidates should be prepared to discuss their experience and qualifications in the following areas:

1. Casing Running Equipment

Candidates should be familiar with the different types of casing running equipment and how to use them safely and efficiently.

2. Casing Running Procedures

Candidates should be familiar with the different casing running procedures and how to follow them safely and efficiently.

3. Safety Regulations and Procedures

Candidates should be familiar with all safety regulations and procedures related to casing running operations.

4. Teamwork and Communication Skills

Casing Running Machine Tenders must be able to work effectively as part of a team and communicate clearly with other members of the drilling crew.

Interview Preparation Tips

In addition to preparing for the technical aspects of the interview, candidates should also be prepared to discuss their:

- Motivation for applying for the position

- Career goals

- Availability

- Salary expectations

Candidates should also be prepared to answer questions about their experience and qualifications in the field. They should be able to provide specific examples of their work and how it has benefited their previous employers.

Finally, candidates should be prepared to ask the interviewer questions about the position and the company. This shows that they are interested in the position and the company, and that they are taking the interview seriously.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Casing Running Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!