Are you gearing up for a career in Casing Sewer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Casing Sewer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

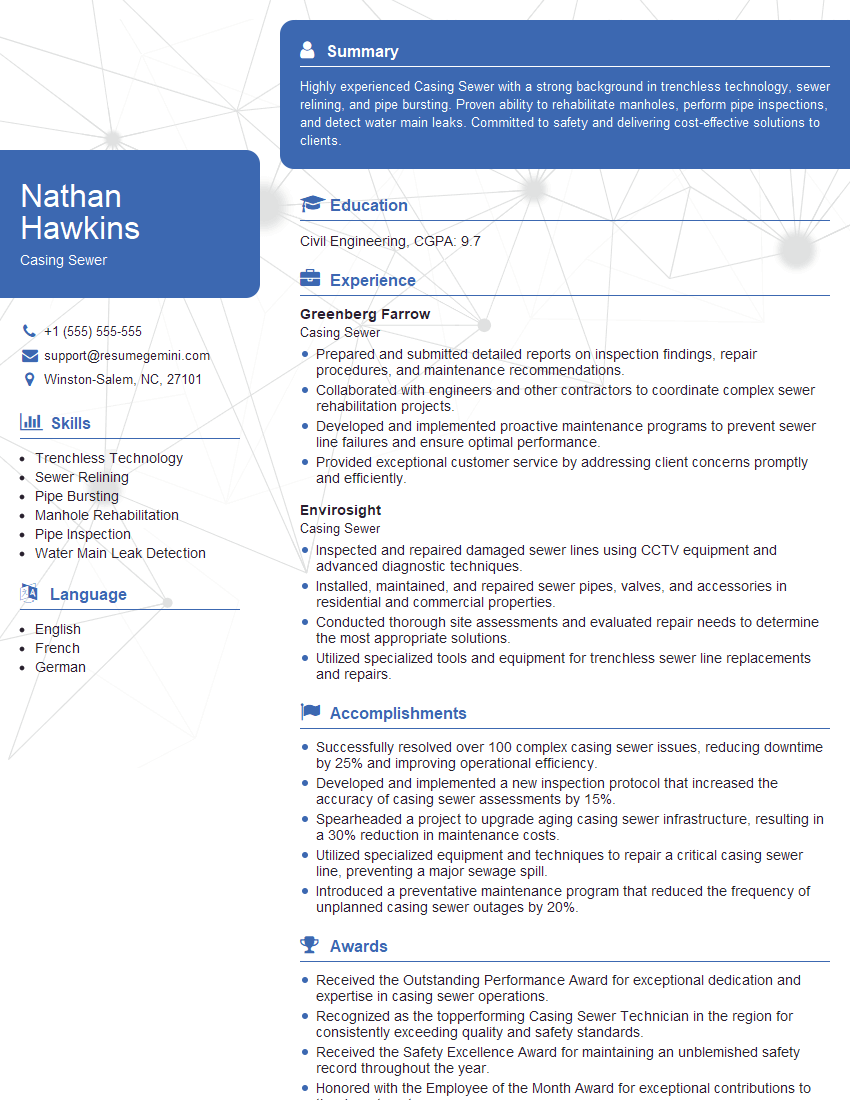

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casing Sewer

1. Can you explain the process of casing a sewer line?

Casing a sewer line is a process of installing a new pipe inside an existing damaged or deteriorated pipe. The new pipe is typically made of a durable material such as PVC or HDPE, and it is inserted into the old pipe using a variety of methods, including pulling, pushing, or bursting. The new pipe is then connected to the existing sewer system, and the old pipe is abandoned in place.

- Excavate a pit at the start of the section to be cased.

- Insert the new pipe into the pit and connect it to the existing sewer system.

- Pull or push the new pipe through the old pipe using a variety of methods.

- Connect the new pipe to the existing sewer system at the end of the section to be cased.

- Backfill the pit and restore the surface to its original condition.

2. What are the different types of casing materials used in sewer line repair?

PVC

- Polyvinyl chloride (PVC) is a lightweight and durable material that is resistant to corrosion and abrasion.

- PVC is also relatively inexpensive, making it a popular choice for casing sewer lines.

HDPE

- High-density polyethylene (HDPE) is a strong and flexible material that is resistant to chemicals and UV radiation.

- HDPE is also more expensive than PVC, but it is often used in applications where strength and durability are important.

GRP

- Glass-reinforced plastic (GRP) is a composite material made of fiberglass and resin.

- GRP is strong and durable, and it is also resistant to corrosion and chemicals.

- GRP is more expensive than PVC and HDPE, but it is often used in applications where high strength and durability are required.

3. What are the advantages of using casing to repair a sewer line?

- Casing is a less invasive method of repair than traditional methods, such as excavation and replacement.

- Casing can be used to repair sewer lines in a variety of locations, including under roads, buildings, and other structures.

- Casing is a cost-effective way to repair sewer lines, as it does not require the excavation of the entire line.

- Casing can extend the life of a sewer line by protecting it from corrosion and other damage.

4. What are the challenges of casing a sewer line?

- Casing can be difficult to install in some locations, such as under roads or buildings.

- Casing can be expensive, especially if the sewer line is large or the damage is extensive.

- Casing can sometimes fail, which can lead to the need for further repairs.

5. What are the different methods used to install a casing liner?

Pipe bursting

- Pipe bursting is a method of installing a new pipe by breaking the old pipe and pulling the new pipe into its place.

- Pipe bursting is a relatively fast and efficient method of installation, but it can be disruptive to the surrounding area.

Sliplining

- Sliplining is a method of installing a new pipe by inserting it into the old pipe.

- Sliplining is a less disruptive method of installation than pipe bursting, but it can be more difficult to install in some cases.

Cured-in-place pipe (CIPP)

- CIPP is a method of installing a new pipe by lining the old pipe with a resin-soaked fabric.

- The fabric is then cured in place, creating a new, seamless pipe.

- CIPP is a relatively non-invasive method of installation, but it can be more expensive than other methods.

6. What are the factors to consider when choosing a casing method?

- The size and condition of the existing sewer line.

- The location of the sewer line.

- The budget for the repair.

- The availability of skilled labor.

7. What are the safety precautions that must be taken when casing a sewer line?

- Wear appropriate personal protective equipment, including gloves, safety glasses, and a hard hat.

- Be aware of the location of underground utilities before digging.

- Use proper excavation techniques to prevent cave-ins.

- Follow all manufacturer’s instructions for the casing materials and equipment.

- Be aware of the potential for hazardous gases and take appropriate precautions.

8. What are the quality control procedures that should be followed when casing a sewer line?

- Inspect the existing sewer line before and after casing to ensure that the new pipe is installed properly.

- Test the new pipe to ensure that it is watertight and free of leaks.

- Document the installation process and the results of the testing.

9. What are the maintenance requirements for a cased sewer line?

- Cased sewer lines require less maintenance than traditional sewer lines, but they should still be inspected and cleaned on a regular basis.

- The frequency of inspection and cleaning will depend on the condition of the sewer line and the surrounding environment.

10. What are the benefits of using a casing system to rehabilitate a sewer line?

- Casing systems can extend the life of a sewer line by protecting it from corrosion and other damage.

- Casing systems can improve the flow capacity of a sewer line by creating a smooth, new surface for the water to flow through.

- Casing systems can reduce the risk of leaks and backups.

- Casing systems can be installed quickly and efficiently, with minimal disruption to the surrounding area.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casing Sewer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casing Sewer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Casing Sewer is responsible for the installation, repair, and maintenance of underground casing and sewer systems. They work with a variety of materials, including PVC, concrete, and metal, and use specialized equipment to complete their tasks.

1. Installation of Casing and Sewer Systems

Casing Sewers install new casing and sewer systems as part of new construction projects or to replace old or damaged systems. They work closely with engineers and other construction professionals to ensure that the system is installed correctly and meets all applicable codes and regulations.

- Excavate trenches for casing and sewer pipes

- Lay and connect casing and sewer pipes

- Backfill trenches and compact soil

2. Repair and Maintenance of Casing and Sewer Systems

Casing Sewers also perform repairs and maintenance on existing casing and sewer systems. They may need to repair leaks, unclog drains, or replace damaged pipes. They also perform regular maintenance tasks, such as cleaning and inspecting the system, to prevent problems from occurring.

- Locate and repair leaks in casing and sewer pipes

- Unclog drains and remove blockages

- Replace damaged casing and sewer pipes

- Clean and inspect casing and sewer systems

3. Safety and Compliance

Casing Sewers must be familiar with and follow all safety regulations and procedures. They must also be aware of and comply with all applicable environmental regulations.

- Follow all safety regulations and procedures

- Comply with all applicable environmental regulations

- Wear appropriate personal protective equipment (PPE)

- Use proper tools and equipment

4. Customer Service

Casing Sewers often work directly with customers to resolve problems and answer questions. They must be able to communicate effectively and provide excellent customer service.

- Answer customer questions and resolve problems

- Provide excellent customer service

- Maintain a positive attitude

- Be willing to go the extra mile

Interview Tips

Preparing for an interview can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Take some time to learn about the company you’re applying to and the specific position you’re interviewing for. This will help you understand the company’s culture, values, and goals, and it will also help you tailor your answers to the interviewer’s questions.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work at the company

2. Practice Answering Common Interview Questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s a good idea to practice answering these questions ahead of time so that you can deliver your answers confidently and concisely.

- Use the STAR method to answer behavioral questions

- Focus on your skills and experience

- Be concise and specific

3. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This shows the interviewer that you’re respectful of their time and that you’re serious about the position.

- Wear clean, pressed clothes

- Be well-groomed

- Arrive on time

4. Be Yourself and Be Enthusiastic

The most important thing is to be yourself and to be enthusiastic about the position. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. And if you’re genuinely interested in the position, your enthusiasm will shine through.

- Be authentic

- Be enthusiastic

- Show your passion for the position

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Casing Sewer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.