Are you gearing up for a career in Cast Iron Dipper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cast Iron Dipper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

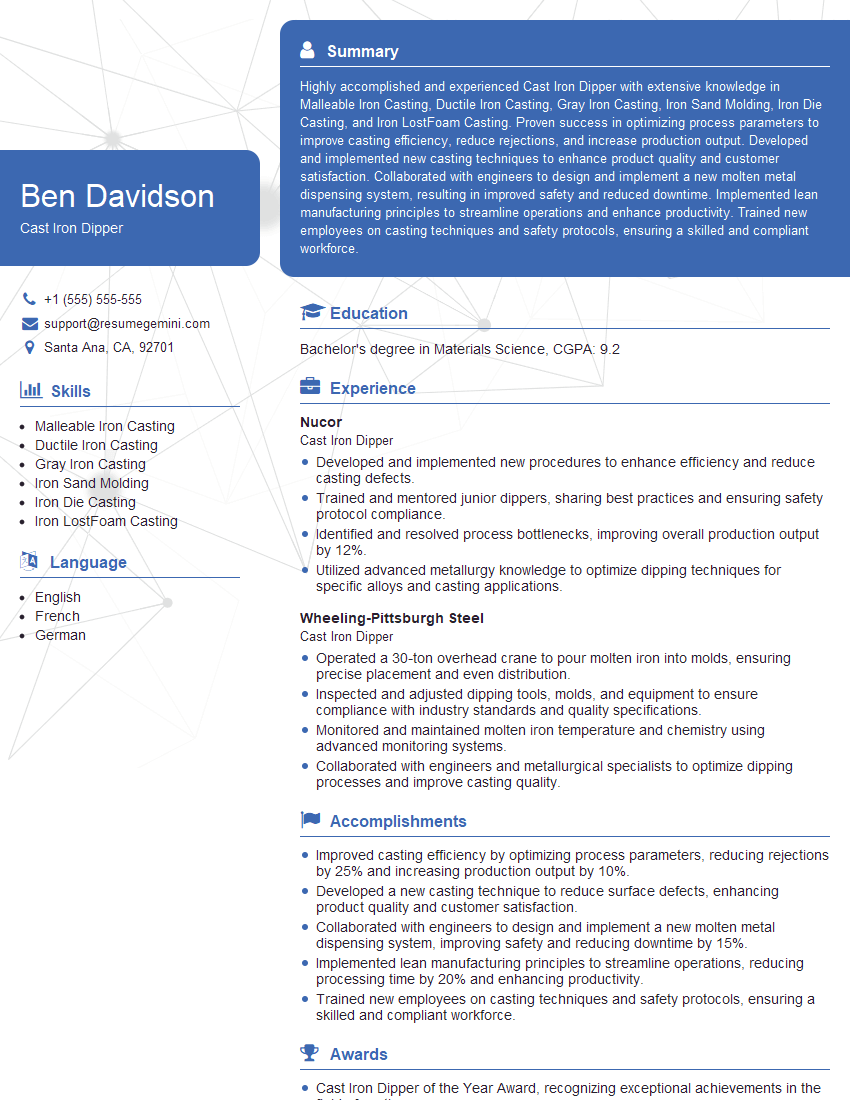

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cast Iron Dipper

1. Tell me about your experience with casting iron?

I have over 10 years of experience working with cast iron. I have worked in a variety of settings, including foundries, machine shops, and fabrication shops. I am proficient in all aspects of cast iron casting, including pattern making, molding, pouring, and finishing.

- pattern making

- molding

- pouring

- finishing

2. What are the different types of cast iron?

Gray iron

- most common type of cast iron

- contains graphite flakes

- good machinability

Ductile iron

- contains spheroidal graphite

- stronger and tougher than gray iron

- good ductility

Malleable iron

- contains temper carbon

- strong and tough

- good machinability

White iron

- contains combined carbon

- hard and brittle

- good wear resistance

3. What are the advantages of casting iron?

- high strength and hardness

- good wear resistance

- low cost

- easy to cast

4. What are the disadvantages of casting iron?

- brittle

- not as strong as steel

- can be difficult to machine

5. What are the different applications for cast iron?

- automotive parts

- machine parts

- construction materials

- art and sculpture

6. What are some of the challenges of casting iron?

- controlling the cooling rate

- preventing defects such as shrinkage, porosity, and cold shuts

- achieving the desired mechanical properties

7. How do you ensure the quality of cast iron castings?

- using high-quality materials

- following proper casting procedures

- inspecting castings for defects

- testing castings to ensure they meet the required specifications

8. What are the latest trends in cast iron casting?

- use of lighter and stronger alloys

- development of new casting techniques

- use of computer-aided design and manufacturing (CAD/CAM)

9. How do you stay up-to-date on the latest developments in cast iron casting?

- read trade publications

- attend industry conferences

- talk to other professionals in the field

10. What are your goals for this position?

- I am eager to learn more about cast iron casting and to contribute my skills to the team.

- I am confident that I can make a significant contribution to your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cast Iron Dipper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cast Iron Dipper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Cast Iron Dipper is responsible for operating and maintaining the cast iron dipping machine, which coats metal products with molten metal. The primary objective of this role is to ensure the smooth and efficient operation of the dipping process while maintaining high-quality standards and adhering to safety regulations.

1. Machine Operation and Maintenance

- Operate the cast iron dipping machine to coat metal products with molten metal.

- Monitor machine parameters, such as temperature, pressure, and flow rate, to ensure optimal performance.

- Perform routine maintenance tasks, including cleaning, lubricating, and adjusting the machine.

- Identify and troubleshoot mechanical or electrical issues and take appropriate corrective actions.

2. Quality Control

- Inspect coated products to ensure adherence to specifications and quality standards.

- Identify and rectify any defects or inconsistencies in the coating process.

- Maintain records of inspection results and any necessary corrective actions taken.

3. Safety and Compliance

- Adhere to established safety protocols and wear appropriate personal protective equipment (PPE).

- Ensure a clean and organized work area to minimize hazards.

- Follow environmental regulations and waste management procedures.

4. Communication and Teamwork

- Communicate effectively with supervisors, colleagues, and customers to ensure smooth operations and resolve issues promptly.

- Work as part of a team to achieve production targets and maintain a positive work environment.

Interview Tips

To ace an interview for the Cast Iron Dipper position, candidates should focus on showcasing their technical skills, attention to detail, and commitment to safety. Here are some tips to help you prepare:

1. Research the Company and Role

- Thoroughly research the company’s history, products, and industry standing.

- Carefully review the job description to understand the specific requirements and responsibilities.

2. Prepare for Technical Questions

- Review the principles of metal coating and the operation of cast iron dipping machines.

- Be prepared to discuss your experience in troubleshooting and maintaining machinery.

- Practice explaining your understanding of quality control processes and defect identification.

3. Highlight Safety Knowledge

- Emphasize your understanding of safety protocols in a manufacturing environment.

- Explain how you prioritize safety in your work practices and maintain a clean and organized workspace.

4. Demonstrate Communication Skills

- Provide examples of effective communication in previous roles, particularly in teamwork settings.

- Practice articulating your thoughts clearly and concisely.

5. Prepare for Common Interview Questions

- Review common interview questions such as “Tell me about yourself” and “Why are you interested in this role?”

- Craft answers that highlight your relevant skills and experience.

6. Prepare Questions for the Interviewer

- Ask thoughtful questions about the company’s operations, the team you would be joining, or the specific challenges of the role.

- This shows your engagement and interest in the position.

7. Dress Professionally and Arrive Early

- Dress appropriately for a professional setting.

- Plan to arrive at the interview venue with ample time to spare.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cast Iron Dipper role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.