Feeling lost in a sea of interview questions? Landed that dream interview for Casting Finisher but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Casting Finisher interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

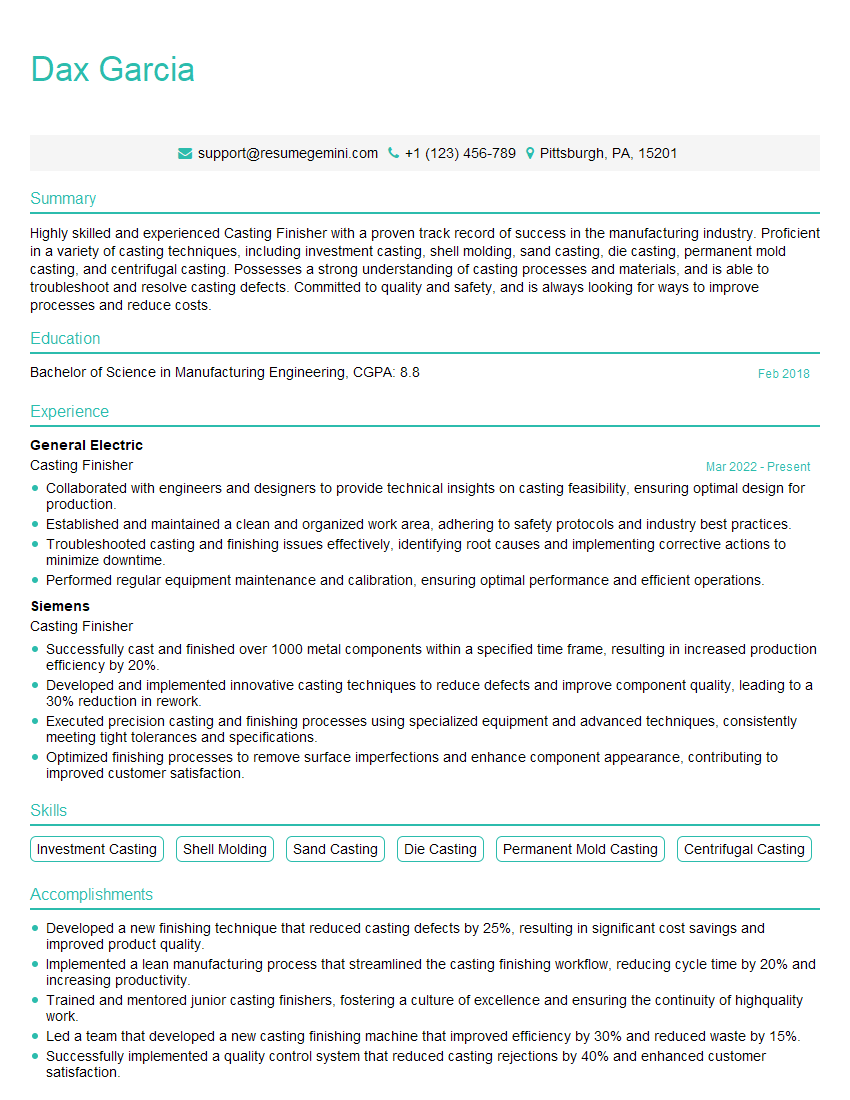

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casting Finisher

1. Describe the steps involved in finishing a cast metal part?

- Inspect the casting for any defects or imperfections.

- Grind or file away any rough edges or excess material.

- Sand the surface of the casting to smooth it out.

- Clean the casting to remove any dust or debris.

- Apply a primer or paint to protect the casting from corrosion.

2. What are the different types of finishing techniques used for cast metal parts?

Sandblasting

- Abrasive blasting process that uses a stream of sand or other abrasive material to smooth and clean the surface of a casting.

- Can be used to remove burrs, flash, and other imperfections.

Shot peening

- Process that uses a stream of small steel shot to impact the surface of a casting.

- Strengthens the casting and reduces the risk of fatigue failure.

3. What are the different types of abrasives used in sandblasting?

- Ceramic beads

- Glass beads

- Sand

- Steel shot

4. What are the safety precautions that must be taken when sandblasting?

- Wear appropriate personal protective equipment (PPE), including a respirator, gloves, and safety glasses.

- Use a well-ventilated area.

- Dispose of spent abrasive material properly.

5. What are the different types of primers and paints used for cast metal parts?

- Epoxy primers

- Urethane primers

- Acrylic primers

- Alkyd paints

- Epoxy paints

6. What are the factors to consider when selecting a primer or paint for a cast metal part?

- The type of metal

- The intended use of the part

- The environmental conditions the part will be exposed to

7. What are the different methods used to apply primers and paints to cast metal parts?

- Spraying

- Brushing

- Rolling

- Dipping

8. What are the quality control checks that must be performed after finishing a cast metal part?

- Visual inspection

- Dimensional inspection

- Surface roughness measurement

- Coating thickness measurement

9. What are the common problems that can occur during the finishing process and how can they be prevented?

- Problem: Burrs and flash Prevention: Use sharp tooling and proper casting techniques.

- Problem: Surface roughness Prevention: Use the proper grit size and technique when sanding.

- Problem: Corrosion Prevention: Apply a primer or paint to protect the casting from the elements.

10. Describe the differences between different surface finishes, such as matte, satin, and gloss.

- Matte: Dull, non-reflective finish.

- Satin: Semi-gloss finish with a slight sheen.

- Gloss: Shiny, reflective finish.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casting Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casting Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Casting Finishers are responsible for ensuring the quality of cast metal parts. They perform a variety of tasks, including:

1. Inspecting castings for defects

Casting Finishers visually inspect castings for any defects, such as cracks, voids, or inclusions. They use a variety of tools to perform this inspection, including magnifying glasses, calipers, and gauges.

2. Removing defects from castings

Casting Finishers remove defects from castings using a variety of methods, such as grinding, sanding, and polishing. They also may use chemicals to remove burrs and other surface imperfections.

3. Preparing castings for further processing

Casting Finishers prepare castings for further processing by cleaning them and applying surface treatments. They may also perform heat treatments to improve the properties of the castings.

4. Maintaining equipment

Casting Finishers maintain the equipment they use to perform their job. This includes cleaning, lubricating, and calibrating equipment.

Interview Tips

To help you ace your interview for a Casting Finisher position, here are some tips:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

2. Practice your answers to common interview questions

There are certain questions that you are likely to be asked in an interview for a Casting Finisher position. Take some time to practice your answers to these questions so that you can deliver them confidently and clearly.

3. Highlight your skills and experience

In your interview, be sure to highlight the skills and experience that make you a qualified candidate for the Casting Finisher position. Focus on your ability to inspect castings for defects, remove defects from castings, and prepare castings for further processing.

4. Ask questions

At the end of your interview, be sure to ask the interviewer questions about the position and the company. This will show that you are interested in the job and that you are eager to learn more about the company.

Next Step:

Now that you’re armed with the knowledge of Casting Finisher interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Casting Finisher positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini