Are you gearing up for an interview for a Casting Machine Set-Up Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Casting Machine Set-Up Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

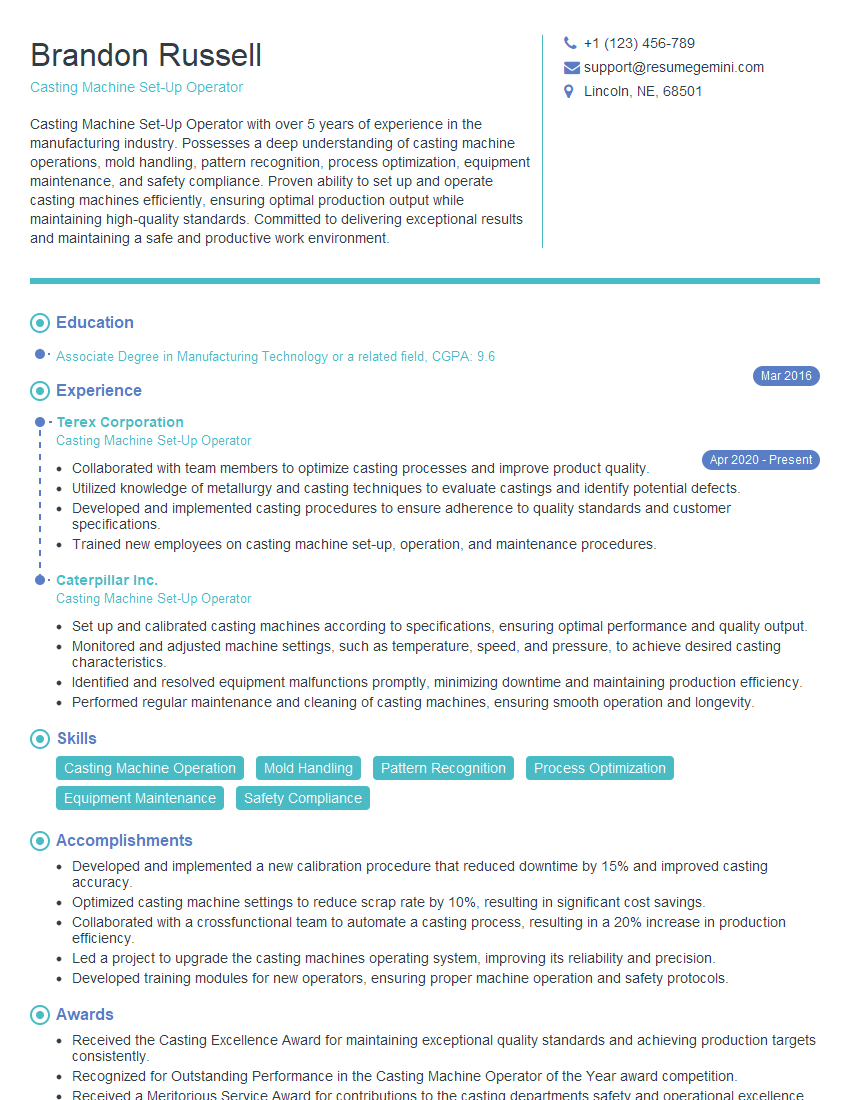

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casting Machine Set-Up Operator

1. What is the purpose of a casting machine in metalworking?

The primary purpose of a casting machine in metalworking is to transform molten metal into solid castings through a process known as metal casting. This process involves pouring molten metal into a mold, allowing it to solidify and take the shape of the mold cavity. The resulting castings are then used in the manufacturing of various components and products.

2. Describe the key components of a casting machine and their functions.

Molding Box

- Holds the mold and supports the molten metal during pouring.

- Ensures the mold maintains its shape and prevents distortion or breakage.

Pattern Plate

- Imparts the desired shape to the molten metal.

- Can be made of various materials, such as wood, metal, or plastic.

Pouring Basin

- Serves as a reservoir to hold molten metal before it is poured into the mold.

- Facilitates smooth and controlled pouring.

Sprue

- A vertical channel that connects the pouring basin to the mold cavity.

- Guides the molten metal into the mold.

Gating System

- A network of channels that distribute the molten metal from the sprue to the mold cavity.

- Ensures proper filling of the mold and prevents defects.

3. Explain the different types of casting machines and their applications.

- Sand Casting: Uses sand molds to create castings. Ideal for low-volume production and intricate designs.

- Investment Casting: Employs a wax pattern and ceramic mold. Produces high-precision castings with smooth surfaces.

- Die Casting: Involves injecting molten metal into a metal mold under high pressure. Suitable for mass production with tight tolerances.

- Centrifugal Casting: Rotates the mold to distribute molten metal evenly. Creates castings with dense and uniform structures.

4. Discuss the safety precautions that must be observed when operating a casting machine.

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a foundry apron.

- Maintain a clean and organized work area to prevent tripping and other accidents.

- Inspect the casting machine regularly to ensure it is in good working order.

- Follow manufacturer’s instructions for operating the machine safely.

- Be aware of molten metal hazards and take precautions to prevent burns or splashes.

5. Describe the process of setting up a casting machine for operation.

- Prepare the mold and pattern plate according to the specifications.

- Assemble the mold in the molding box and secure it properly.

- Position the pouring basin and sprue to ensure proper metal flow.

- Check all connections and components to ensure they are secure and functioning correctly.

- Test the machine by running a small test pour to verify its operation.

6. How do you ensure the quality of castings produced by a casting machine?

- Control the temperature of the molten metal to prevent defects such as cold shuts or porosity.

- Maintain the proper pouring rate to avoid turbulence and slag inclusions.

- Inspect the castings after solidification to identify any defects or nonconformities.

- Make adjustments to the casting process based on quality control feedback to improve casting quality.

7. Explain how you troubleshoot common problems encountered in casting machine operation.

- Incomplete casting: Check metal temperature, pouring rate, and gating system design.

- Gas porosity: Investigate mold moisture, trapped air, or insufficient degassing of molten metal.

- Cracks: Analyze casting design, cooling rate, and mold material to identify potential causes.

- Dimensional inaccuracies: Examine mold dimensions, pattern accuracy, and equipment calibration.

- Cold shuts: Ensure proper metal temperature, pouring technique, and gating system design.

8. Describe the maintenance procedures for a casting machine.

- Regularly clean and inspect all components, including the mold, pouring basin, and gating system.

- Lubricate moving parts as per manufacturer’s instructions.

- Check and tighten electrical connections to prevent arcing or overheating.

- Calibrate the machine periodically to ensure accurate operation.

- Store the machine properly when not in use to prevent rust and damage.

9. What are the key skills and qualities required to be an effective Casting Machine Set-Up Operator?

- Technical knowledge of casting processes and equipment.

- Mechanical aptitude for setting up and maintaining machines.

- Attention to detail and accuracy in following instructions.

- Good communication skills to interact with colleagues and supervisors.

- Strong work ethic and willingness to learn and improve.

10. How do you stay up-to-date with the latest advancements in casting technology?

- Attend industry conferences and seminars to learn about new techniques and equipment.

- Read trade publications and technical journals to stay informed about industry trends.

- Participate in online forums and discussion groups to exchange knowledge and ideas with other professionals.

- Seek opportunities for professional development, such as training courses and certifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casting Machine Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casting Machine Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Casting Machine Set-Up Operator plays a crucial role in the production process by setting up, operating, and maintaining casting machines. Their primary responsibilities include:

1. Machine Setup and Operation

Set up, adjust, and calibrate casting machines according to product specifications and process requirements.

- Load and position molds, dies, and other tooling.

- Monitor and control machine parameters, such as temperature, speed, and pressure.

- Troubleshoot and resolve any issues related to machine setup and operation.

2. Material Handling

Handle and transport raw materials and finished products safely and efficiently.

- Operate conveyor systems and other material handling equipment.

- Ensure proper storage and handling of materials to maintain quality and prevent contamination.

3. Quality Control

Inspect and monitor the quality of castings produced by the casting machines.

- Identify and correct any defects in the casting process.

- Maintain records and documentation related to casting quality.

4. Machine Maintenance

Perform routine maintenance and repairs on casting machines to ensure optimal performance.

- Lubricate and clean machines regularly.

- Perform minor repairs and adjustments.

- Report any major issues or maintenance needs to supervisors.

Interview Tips

Preparing thoroughly for a Casting Machine Set-Up Operator interview is essential to showcase your skills and increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company, their products, and the specific role you are applying for. This will demonstrate your interest and preparation.

- Read the job description carefully and identify the key responsibilities and qualifications.

- Visit the company website to learn about their business operations, culture, and values.

2. Highlight Your Technical Skills

Emphasize your technical skills related to casting machine setup, operation, and maintenance. Quantify your experience with specific examples.

- Describe your experience in setting up and calibrating casting machines.

- Provide examples of how you have successfully handled material handling operations.

- Explain your knowledge of quality control procedures and your ability to troubleshoot and resolve casting issues.

3. Showcase Your Problem-Solving Abilities

Casting Machine Set-Up Operators often encounter unexpected challenges. Highlight your problem-solving skills and provide examples of how you have overcome obstacles in the past.

- Discuss a time when you identified and resolved a machine malfunction.

- Describe how you approached a quality issue and implemented corrective actions.

4. Prepare for Common Interview Questions

Practice answering common interview questions related to your experience, skills, and motivations. Some typical questions include:

- Tell me about your experience in setting up and operating casting machines.

- How do you ensure the quality of castings produced by the machines?

- What are your strengths and weaknesses as a Casting Machine Set-Up Operator?

5. Ask Informed Questions

At the end of the interview, take the opportunity to ask thoughtful questions about the position, the company, and the industry. This shows your engagement and interest.

- Inquire about the company’s growth plans and technological advancements.

- Ask about opportunities for professional development and training.

Conclusion

By following these tips, you can prepare effectively for your Casting Machine Set-Up Operator interview and increase your chances of landing the job.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Casting Machine Set-Up Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.