Are you gearing up for a career in Casting Molder? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Casting Molder and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

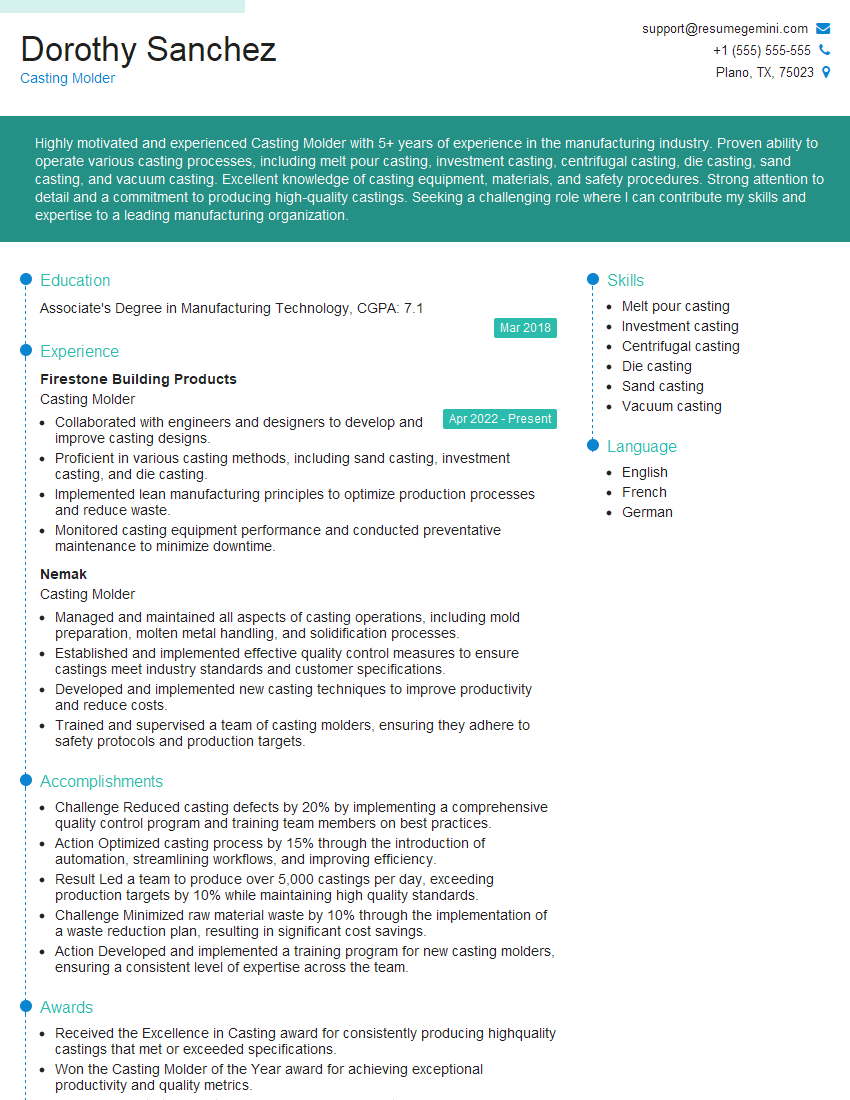

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casting Molder

1. What are the different types of casting methods used in the industry?

There are several types of casting methods used in the industry, including:

- Sand casting

- Investment casting

- Die casting

- Centrifugal casting

- Permanent mold casting

2. What are the key factors to consider when selecting a casting method?

Factors to consider

- Type of metal being cast

- Size and complexity of the part

- Production volume

- Cost

Best casting method

- For small, complex parts, investment casting is a good option.

- For large, simple parts, sand casting is a good option.

- For high-volume production, die casting is a good option.

3. What are the common defects that can occur in casting and how can they be prevented?

- Porosity: Caused by gas bubbles trapped in the metal. Can be prevented by degassing the metal before casting.

- Shrinkage: Caused by the metal shrinking as it cools. Can be prevented by using a mold that is slightly larger than the desired part size.

- Cold shuts: Caused by the metal not completely filling the mold. Can be prevented by ensuring that the mold is properly heated and that the metal is poured at the correct temperature.

4. What are the different types of mold materials used in casting?

- Sand: Inexpensive and easy to use, but not very precise.

- Investment: Made of a ceramic material, provides high precision but is more expensive.

- Die: Made of metal, provides the highest precision but is also the most expensive.

- Permanent mold: Made of metal, reusable, and provides good precision and production rates.

5. What are the steps involved in the sand casting process?

- Create a pattern: A model of the desired part is made.

- Make a mold: A mold is made around the pattern using sand.

- Pour the metal: Molten metal is poured into the mold.

- Allow the metal to cool: The metal is allowed to cool and solidify.

- Remove the casting: The casting is removed from the mold.

6. What are the advantages and disadvantages of investment casting?

Advantages

- High precision

- Can produce complex shapes

- Good surface finish

Disadvantages

- Expensive

- Time-consuming

- Not suitable for high-volume production.

7. What are the safety precautions that should be taken when working with molten metal?

- Wear appropriate protective clothing: This includes gloves, safety glasses, a long-sleeved shirt, and pants.

- Work in a well-ventilated area: Molten metal can release harmful fumes.

- Never pour molten metal into water: This can cause an explosion.

- Be aware of the location of fire extinguishers and other safety equipment.

8. What are the different types of casting defects that can be caused by incorrect gating and risering?

Incorrect gating

- Cold shuts

- Misruns

- Turbulence

Incorrect risering

- Shrinkage cavities

- Porosity

- Hot tears.

9. How can you determine the correct pouring temperature for a particular metal?

- Consult the metal’s datasheet: The datasheet will typically list the recommended pouring temperature.

- Use a pyrometer: A pyrometer is a device that can be used to measure the temperature of molten metal.

- Experience: With experience, you will learn to recognize the correct pouring temperature for different metals.

10. What are the different types of casting equipment that you are familiar with?

- Furnaces: Furnaces are used to melt metal.

- Molds: Molds are used to shape molten metal.

- Pouring equipment: Pouring equipment is used to pour molten metal into molds.

- Cleaning and finishing equipment: Cleaning and finishing equipment is used to remove burrs and other imperfections from castings.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casting Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casting Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Casting Molders are responsible for the production of metal castings using various casting techniques. Their duties involve operating casting machines, preparing molds, and ensuring the quality of the final products. Here are some key responsibilities:

1. Mold Preparation

Casting Molders prepare molds by following engineering drawings and specifications. They select and assemble appropriate materials, such as sand, plaster, or metal, to create the desired mold shape.

- Assembling and securing mold components

- Mixing and pouring molding materials

- Inspecting molds for defects or imperfections

2. Machine Operation

They operate various casting machines, such as centrifugal casting machines, investment casting machines, or die casting machines. They set up and adjust machine parameters to ensure proper casting conditions.

- Loading and unloading castings

- Monitoring casting processes

- Troubleshooting and resolving machine issues

3. Casting Production

Casting Molders pour molten metal into prepared molds. They control the pouring temperature, speed, and pressure to ensure proper filling of the mold cavity.

- Preparing and handling molten metal

- Maintaining proper casting temperatures

- Ensuring accurate filling of the mold

4. Quality Control

They inspect castings for defects, such as cracks, voids, or dimensional inaccuracies. They ensure that castings meet the required specifications and quality standards.

- Conducting visual inspections

- Using measurement tools and gauges

- Identifying and reporting any non-conformities

Interview Tips

To prepare for an interview for a Casting Molder position, here are some tips and hacks that can help you ace the interview:

1. Research the Company and Position

Research the company and the specific position you are applying for. This will give you a good understanding of the company’s culture, values, and the requirements of the role.

- Visit the company website

- Read industry news and articles

- Connect with current or former employees on LinkedIn

2. Practice Your Answers

Prepare and practice answers to common interview questions. This will help you articulate your skills, experience, and qualifications effectively during the interview.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers

- Focus on highlighting your relevant skills and experience

- Quantify your accomplishments whenever possible

3. Be Enthusiastic and Professional

Show your enthusiasm for the position and the casting industry. Dress professionally, arrive on time for the interview, and maintain a positive and confident demeanor.

- Smile and make eye contact

- Be respectful and courteous

- Ask thoughtful questions

4. Emphasize Your Technical Skills

Highlight your technical skills and knowledge in casting processes, mold making, and quality control. Discuss your experience with different casting techniques, materials, and equipment.

- Explain your understanding of casting principles

- Describe your experience with specific casting machines

- Showcase your ability to read and interpret technical drawings

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Casting Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!