Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Casting Room Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

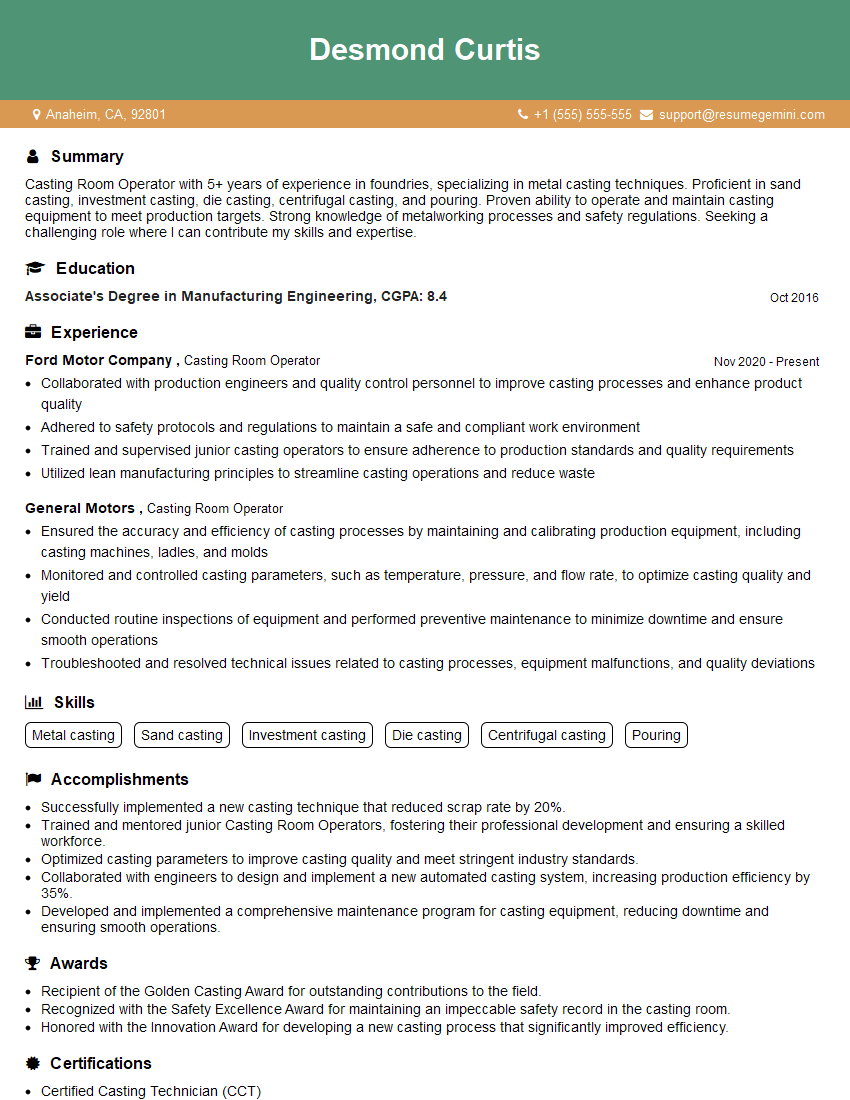

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casting Room Operator

1. Explain the process of centrifugal casting?

Centrifugal casting is a metal casting process that uses centrifugal force to distribute molten metal into a mold. The process begins by pouring molten metal into a rotating mold. The centrifugal force causes the metal to spread evenly throughout the mold, resulting in a casting with a uniform thickness and density. Centrifugal casting is often used to produce castings with complex shapes or thin walls.

- Pour molten metal into a rotating mold.

- Centrifugal force distributes the metal evenly throughout the mold.

- Casting with a uniform thickness and density is produced.

- Often used to produce castings with complex shapes or thin walls.

2. What are the advantages of using a vacuum casting process?

Advantages of vacuum casting

- Produces castings with a high degree of accuracy and detail.

- Eliminates the need for a sprue or runner system, which can reduce material waste and improve casting yield.

- Can be used to cast a wide variety of metals and alloys.

- Produces castings with a smooth surface finish.

3. How do you ensure the quality of castings produced in the casting room?

I ensure the quality of castings produced in the casting room by following a number of quality control procedures. These procedures include:

- Inspecting the raw materials used in the casting process.

- Calibrating and maintaining the casting equipment.

- Following the casting process specifications.

- Inspecting the finished castings for defects.

- Taking corrective action when defects are found.

4. What are the different types of casting defects and how can they be prevented?

There are a number of different types of casting defects, including:

- Shrinkage defects

- Gas defects

- Inclusions

- Cold shuts

- Cracks

These defects can be prevented by following proper casting procedures and using high-quality materials.

5. How do you troubleshoot casting problems?

When troubleshooting casting problems, I first try to identify the type of defect that is occurring. Once I have identified the type of defect, I can then take steps to correct the problem.

- Inspect the casting for defects.

- Identify the type of defect.

- Take steps to correct the problem.

6. What are the safety precautions that must be taken when working in a casting room?

When working in a casting room, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and a respirator.

- Be aware of the location of fire extinguishers and other safety equipment.

- Do not enter the casting room when molten metal is being poured.

- Follow all safety procedures and guidelines.

7. What is the role of a casting room operator?

The role of a casting room operator is to operate and maintain the equipment used in the casting process. This includes:

- Pouring molten metal into molds.

- Operating the casting equipment.

- Maintaining the casting room and equipment.

- Inspecting castings for defects.

8. What are the qualifications required to be a casting room operator?

The qualifications required to be a casting room operator typically include:

- A high school diploma or equivalent.

- Experience in a manufacturing environment.

- Knowledge of casting processes.

- Ability to operate and maintain casting equipment.

- Ability to inspect castings for defects.

9. What is the work environment of a casting room operator?

The work environment of a casting room operator is typically a foundry or other manufacturing facility. The work can be physically demanding and may involve exposure to heat, noise, and dust.

- Foundry or other manufacturing facility.

- Physically demanding.

- Exposure to heat, noise, and dust.

10. What are the career opportunities for a casting room operator?

The career opportunities for a casting room operator can include:

- Advancement to a supervisory role.

- Specialization in a particular casting process.

- Management of a casting department.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casting Room Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casting Room Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Casting Room Operators are responsible for the safe and efficient operation of casting machines in manufacturing facilities. They ensure that molten metal is poured into molds accurately and efficiently to produce metal castings.

1. Machine Operation and Maintenance

Operate and maintain casting machines according to established procedures.

- Monitor machine performance and make adjustments as needed.

- Perform routine maintenance and repairs on casting machines.

2. Material Handling

Handle molten metal and other materials safely and efficiently.

- Load and unload molds from casting machines.

- Dispose of waste materials safely and in accordance with regulations.

3. Quality Assurance

Inspect castings for defects and ensure they meet quality standards.

- Use measuring devices and other tools to verify dimensions and specifications.

- Report any defects or non-conformances to supervisors.

4. Safety and Compliance

Follow safety regulations and adhere to established work practices.

- Wear appropriate personal protective equipment (PPE) at all times.

- Handle molten metal with caution and follow established procedures for its safe use.

Interview Tips

Preparing thoroughly for a Casting Room Operator interview can significantly improve your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Gather information about the company’s industry, products/services, and company culture. Additionally, thoroughly review the job description and identify the specific skills and experience required.

2. Highlight Relevant Skills and Experience

During the interview, emphasize your skills and experience that directly align with the job requirements. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

3. Practice Answering Common Interview Questions

Prepare for common interview questions such as “Tell me about yourself,” “Why are you interested in this role?” and “What are your strengths and weaknesses?” Craft clear and concise answers that showcase your knowledge, skills, and enthusiasm for the position.

4. Be Prepared to Discuss Safety and Quality

Casting Room Operators must prioritize safety and quality in their work. During the interview, demonstrate your understanding of safety regulations and quality standards. Highlight any experience or training you have related to these areas.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your interest in the position and the company. Prepare questions that demonstrate your curiosity, such as “What are the company’s growth plans for the future?” or “What are the opportunities for professional development within the organization?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Casting Room Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.