Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cat Cracker Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

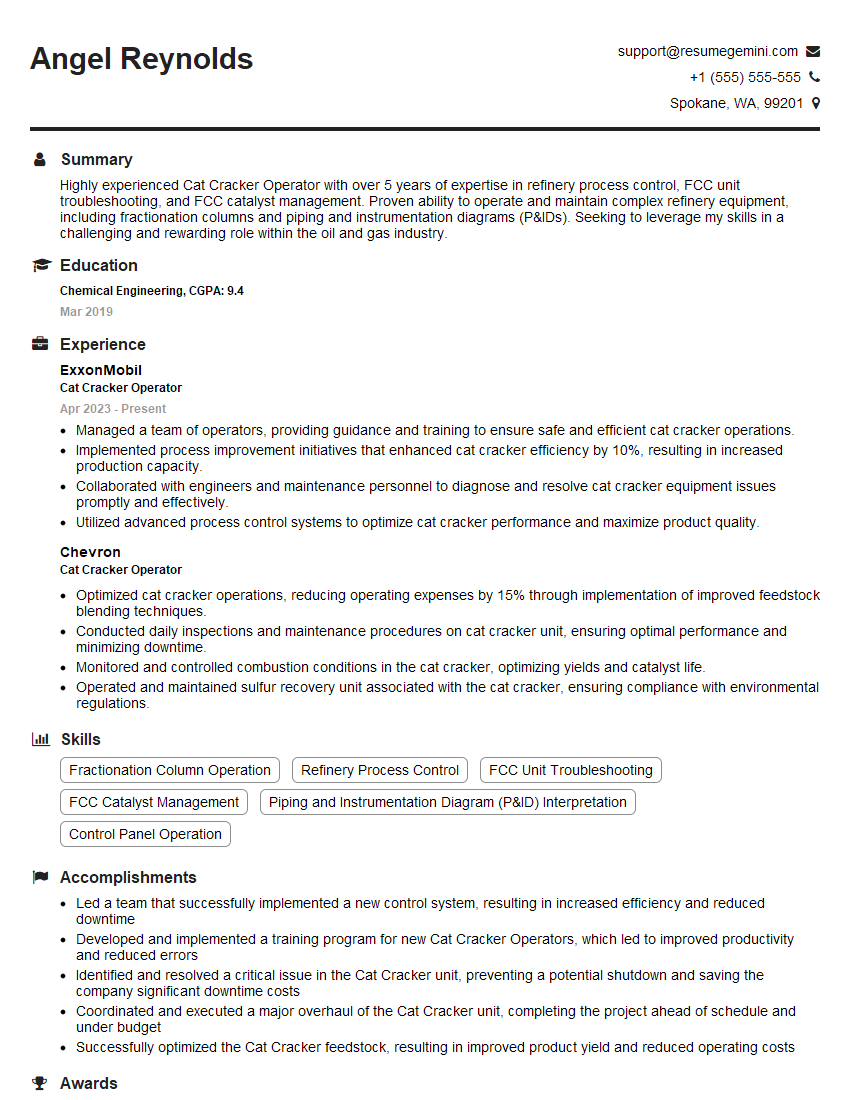

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cat Cracker Operator

1. What are the key operating parameters of a Cat Cracker and how do you monitor and control them?

The key operating parameters of a Cat Cracker are:

- Feed rate

- Temperature

- Pressure

- Catalyst circulation rate

- Product yields

These parameters are monitored and controlled through a combination of instrumentation and process control systems. The operator must have a thorough understanding of the process and the control systems in order to maintain stable operation.

2. Describe the role of the catalyst in a Cat Cracker and how it is regenerated.

Function of the catalyst

- The catalyst in a Cat Cracker is a solid material that provides a surface for the chemical reactions that convert the feedstock into products.

- The catalyst is typically a zeolite, which is a porous material with a high surface area.

- The catalyst is circulated through the reactor where it comes into contact with the feedstock.

Regeneration of the catalyst

- Over time, the catalyst becomes deactivated due to the accumulation of coke and other contaminants.

- To maintain catalyst activity, it must be regenerated.

- Regeneration is typically carried out by burning off the coke in a separate reactor.

3. What are the common operating problems that can occur in a Cat Cracker and how do you troubleshoot them?

Some common operating problems that can occur in a Cat Cracker include:

- Feedstock quality issues: The feedstock to a Cat Cracker can vary in composition, which can affect the process performance.

- Catalyst deactivation: The catalyst can become deactivated over time, which can lead to a decrease in product yields.

- Equipment failures: Equipment failures can occur in any part of the Cat Cracker, which can lead to a shutdown of the unit.

Troubleshooting these problems requires a thorough understanding of the process and the equipment. The operator must be able to identify the root cause of the problem and take corrective action.

4. What are the safety hazards associated with operating a Cat Cracker and how do you mitigate them?

The safety hazards associated with operating a Cat Cracker include:

- Fire and explosion: The Cat Cracker process involves the handling of flammable hydrocarbons, which can create a fire or explosion hazard.

- Toxic chemicals: The Cat Cracker process produces a variety of toxic chemicals, which can be harmful to human health.

- High pressure: The Cat Cracker operates at high pressure, which can create a safety hazard if equipment fails.

To mitigate these hazards, the operator must follow all safety procedures and wear appropriate personal protective equipment. The operator must also be aware of the potential hazards and take steps to avoid them.

5. What are the environmental regulations that apply to Cat Cracker operations and how do you comply with them?

The Cat Cracker process is subject to a number of environmental regulations, including:

- Air pollution regulations: The Cat Cracker process emits a variety of air pollutants, including sulfur dioxide, nitrogen oxides, and particulate matter.

- Water pollution regulations: The Cat Cracker process generates wastewater, which must be treated before it can be discharged to the environment.

- Solid waste regulations: The Cat Cracker process generates solid waste, which must be disposed of in accordance with applicable regulations.

To comply with these regulations, the operator must implement a variety of pollution control measures. These measures may include scrubbers, filters, and waste treatment systems.

6. What are the key performance indicators (KPIs) for a Cat Cracker operation and how do you track and improve them?

The key performance indicators (KPIs) for a Cat Cracker operation include:

- Product yields: The Cat Cracker process produces a variety of products, including gasoline, diesel fuel, and jet fuel.

- Product quality: The quality of the products produced by the Cat Cracker must meet certain specifications.

- Energy efficiency: The Cat Cracker process is energy-intensive.

- Environmental performance: The Cat Cracker process must comply with applicable environmental regulations.

To track and improve these KPIs, the operator must collect data and perform analysis.

7. What are the latest trends in Cat Cracker technology and how do you stay up-to-date with them?

The latest trends in Cat Cracker technology include:

- Advanced catalysts: New catalyst formulations are being developed to improve product yields and reduce emissions.

- Improved process control systems: New process control systems are being developed to improve the efficiency and safety of the Cat Cracker process.

- New feedstocks: Cat Cracker technology is being developed to process new feedstocks, such as biomass and heavy oils.

To stay up-to-date with the latest trends in Cat Cracker technology, the operator must read technical journals and attend industry conferences.

8. How do you handle shift work and overtime?

I am a highly motivated and dedicated individual who is willing to work hard and put in the hours to get the job done. I understand that shift work and overtime may be required in this role, and I am prepared to meet those demands. I have a flexible schedule and am available to work any shift or overtime hours that are needed. I am also a team player and am willing to help out my colleagues when needed.

9. What is your experience with working in a high-pressure environment?

I have worked in a high-pressure environment for the past 5 years as a Cat Cracker Operator at [Previous Company Name]. In this role, I was responsible for the safe and efficient operation of the Cat Cracker unit. I was also responsible for troubleshooting and resolving any problems that arose during operation. I am confident that I have the skills and experience necessary to work safely and efficiently in a high-pressure environment.

10. What is your greatest strength as a Cat Cracker Operator?

My greatest strength as a Cat Cracker Operator is my ability to quickly and accurately troubleshoot and resolve problems. I have a strong understanding of the Cat Cracker process and the equipment involved. I am also a quick learner and I am always eager to improve my skills and knowledge. I am confident that I can use my skills and experience to help your company achieve its goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cat Cracker Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cat Cracker Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cat Cracker Operator is responsible for the safe and efficient operation of a catalytic cracking unit, which is a key component in the refining process.

1. Monitoring and controlling the process

The operator is responsible for monitoring and controlling the various process parameters, such as temperature, pressure, and flow rates, to ensure that the unit is operating within the desired specifications.

- Ensuring the unit is operating within the operational parameters

- Adjusting process variables to maintain desired product quality

- Responding to process upsets and taking corrective actions

2. Troubleshooting and maintaining equipment

The operator is also responsible for troubleshooting and maintaining the equipment associated with the unit, such as pumps, valves, and instruments.

- Identifying and resolving equipment issues

- Performing routine maintenance and repairs

- Ensuring equipment is in good working order

3. Communicating with other operators and staff

The operator must be able to communicate effectively with other operators and staff, both within the unit and in other areas of the refinery.

- Coordinating activities with other operators

- Communicating process information to supervisors and other staff

- Following instructions and adhering to safety procedures

4. Adhering to safety procedures

The operator must adhere to all safety procedures and regulations to ensure the safety of themselves and others.

- Following all safety protocols and guidelines

- Maintaining a clean, organized work area

- Wearing the appropriate personal protective equipment

Interview Tips

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and goals, and to tailor your answers to the specific requirements of the position.

- Visit the company’s website and read about their history, mission, and values.

- Review the job description and make note of the key qualifications and responsibilities.

- Search for news articles and other information about the company to get a sense of their industry standing and recent developments.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your responses confidently and concisely.

- Prepare a brief introduction that highlights your relevant skills and experience.

- Brainstorm reasons why you are interested in the position and the company.

- Consider potential questions about your qualifications and how you would handle specific job responsibilities.

3. Prepare questions to ask the interviewer

Asking thoughtful questions at the end of the interview shows that you are interested in the position and that you have taken the time to prepare. It also gives you an opportunity to learn more about the company and the position.

- Ask about the company’s plans for the future.

- Inquire about the specific challenges and opportunities associated with the position.

- Ask about the company’s culture and work environment.

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you are serious about the position.

- Choose clothing that is clean, pressed, and appropriate for a professional setting.

- Arrive for your interview at least 10 minutes early.

- Be polite and respectful to everyone you encounter, including the receptionist and other employees.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cat Cracker Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!