Feeling lost in a sea of interview questions? Landed that dream interview for Catalyst Unit Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Catalyst Unit Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

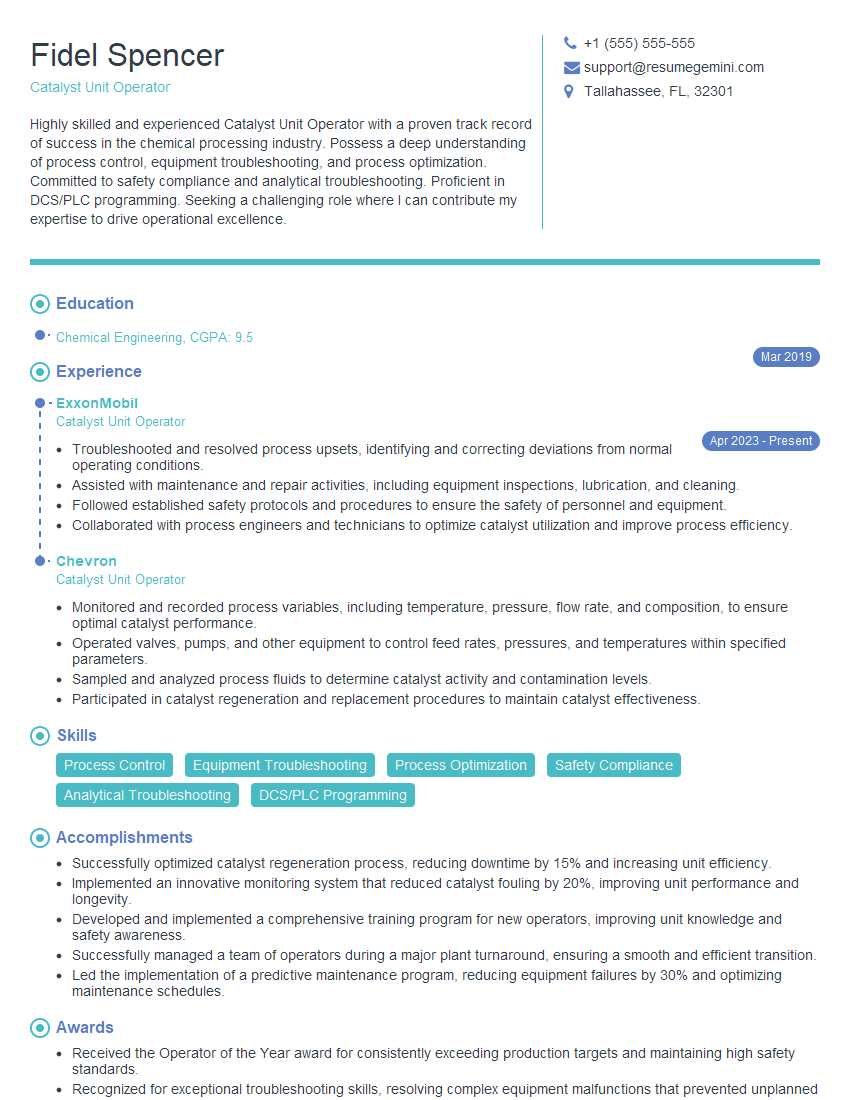

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Catalyst Unit Operator

1. What are the key responsibilities of a Catalyst Unit Operator?

As a Catalyst Unit Operator, my primary responsibilities include:

- Monitoring and controlling the operation of catalyst units, ensuring efficient and safe production.

- Performing routine maintenance, troubleshooting, and resolving operational issues.

- Sampling and analyzing catalyst and feedstock, monitoring process parameters, and making adjustments to optimize unit performance.

- Adhering to safety protocols, maintaining a clean and organized work environment, and following established operating procedures.

- Collaborating with engineers, technicians, and other team members to improve unit efficiency and troubleshoot complex issues.

2. Explain the process of catalyst regeneration.

Catalyst Deactivation and Regeneration

- Catalyst deactivation occurs over time due to factors such as coking, poisoning, and metal deposition.

- Regeneration involves removing these contaminants and restoring the catalyst’s activity.

Regeneration Methods

- Thermal Regeneration: Using heat to burn off coke and other deposits.

- Chemical Regeneration: Using chemicals to dissolve or react with contaminants.

- Hydrothermal Regeneration: Combining heat and water to remove deposits.

3. Describe the safety procedures you follow when operating a catalyst unit.

Safety is paramount in catalyst unit operations. I strictly adhere to established safety protocols, including:

- Wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and respirators.

- Following lockout/tagout procedures before performing maintenance or repairs.

- Maintaining a clean and organized work area, free of hazards and potential ignition sources.

- Being aware of potential hazards such as high temperatures, pressure, and corrosive materials.

- Reporting any safety concerns or incidents promptly to supervisors and following emergency response procedures.

4. What are the common troubleshooting techniques you use to resolve unit malfunctions?

When troubleshooting unit malfunctions, I follow a systematic approach, including:

- Identify the Problem: Determine the symptoms and gather data from sensors, gauges, and logs.

- Analyze the Cause: Use knowledge of the unit and process to identify potential causes.

- Implement Corrective Actions: Take appropriate steps to resolve the issue, such as adjusting process parameters, cleaning equipment, or replacing components.

- Monitor and Verify: Observe unit performance and ensure that the issue has been resolved.

- Document and Report: Record the troubleshooting process, corrective actions taken, and any recommendations for future improvements.

5. How do you optimize catalyst unit performance?

Optimizing catalyst unit performance involves:

- Regular Monitoring: Tracking key process parameters and analyzing data to identify areas for improvement.

- Catalyst Management: Maintaining optimal catalyst activity through regeneration, replacement, and deactivation monitoring.

- Process Optimization: Adjusting operating conditions, such as temperature, pressure, and flow rates, to maximize yield and efficiency.

- Equipment Maintenance: Ensuring that all equipment is in good working order to minimize downtime and improve unit reliability.

- Collaboration: Working with engineers, technicians, and other team members to develop and implement performance improvement strategies.

6. Describe your experience with process control systems used in catalyst unit operations.

I am proficient in using process control systems (PCS), including:

- Distributed Control Systems (DCS): Monitoring and controlling unit operations through a centralized system.

- Programmable Logic Controllers (PLCs): Automating specific control functions and interfacing with field devices.

- Human-Machine Interfaces (HMIs): Providing operators with a user-friendly interface to interact with the PCS.

- Data Acquisition and Monitoring Systems: Collecting and analyzing process data for performance optimization.

7. What are the challenges you have faced as a Catalyst Unit Operator and how did you overcome them?

One significant challenge I faced was a catalyst deactivation issue that resulted in reduced unit efficiency. I collaborated with engineers to analyze the cause, which was determined to be metal poisoning from a contaminated feedstock. We implemented a new feedstock pre-treatment process to remove the contaminants and restore catalyst activity.

8. How do you stay up-to-date with advancements in catalyst technology and unit operations?

I am committed to continuous learning and staying abreast of industry advancements. I attend industry conferences, read technical journals, and participate in training programs to enhance my knowledge and skills. I also actively engage with vendors and experts to stay informed about the latest technologies and best practices.

9. Describe a time when you had to work under pressure to resolve a critical issue in a catalyst unit.

During a routine inspection, we detected a leak in a critical valve that could potentially impact unit operations. Time was of the essence to prevent a shutdown. I immediately isolated the valve, coordinated with maintenance, and worked under pressure to replace the valve within a short time frame. My quick response and collaboration with the team ensured minimal disruption to the unit’s operation.

10. What are your career goals as a Catalyst Unit Operator?

I aspire to grow within my role and contribute to the overall success of the organization. I am eager to take on additional responsibilities and challenges, such as leading process improvement initiatives or mentoring junior operators. My ultimate career goal is to become a Catalyst Unit Supervisor, where I can leverage my expertise to optimize unit operations and drive performance excellence.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Catalyst Unit Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Catalyst Unit Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Catalyst Unit Operators hold a critical role in the chemical processing industry, where they are accountable for the efficient and safe operation of catalyst units. Their key responsibilities encompass a wide range of tasks, including:

1. Catalyst Monitoring and Management

Ensuring optimal catalyst performance by monitoring its activity, selectivity, and regeneration cycles.

- Conducting periodic inspections to assess catalyst condition.

- Sampling and analyzing catalyst samples to monitor its properties.

2. Catalyst Replacement and Regeneration

Maintaining catalyst effectiveness through regular replacement and regeneration processes.

- Safely unloading spent catalyst and loading fresh catalyst into the reactor.

- Initiating and overseeing catalyst regeneration procedures.

3. Process Control and Optimization

Ensuring efficient and optimized process performance by adjusting operating parameters.

- Monitoring process variables such as temperature, pressure, and flow rates.

- Making adjustments to process controls to maintain desired reaction conditions.

4. Equipment Maintenance and Troubleshooting

Maintaining equipment reliability and preventing unplanned downtime.

- Performing routine inspections and preventive maintenance on catalyst unit components.

- Troubleshooting and resolving equipment malfunctions to minimize disruptions.

5. Safety and Environmental Compliance

Adhering to strict safety protocols and environmental regulations.

- Operating equipment in accordance with established safety guidelines.

- Monitoring environmental emissions and ensuring compliance with regulations.

Interview Tips

To prepare effectively for an interview as a Catalyst Unit Operator, consider the following tips:

1. Research the Company and Position

Demonstrate your enthusiasm and preparedness by thoroughly researching the company, its industry, and the specific job requirements. This will help you tailor your answers to the interviewer’s expectations and show that you are genuinely interested in the role.

- Visit the company’s website to learn about its mission, values, and recent developments.

- Review the job description carefully to identify the essential skills and responsibilities.

2. Highlight Relevant Experience and Skills

During the interview, emphasize your practical experience in catalyst unit operations and relevant technical skills. Quantify your accomplishments whenever possible to demonstrate your impact.

- Describe your experience in monitoring and managing catalyst performance.

- Provide examples of successful catalyst replacement and regeneration procedures you have carried out.

3. Demonstrate Problem-Solving Abilities

Interviewers often seek candidates with strong problem-solving abilities. Prepare examples of how you have identified and resolved issues in your previous roles.

- Discuss a situation where you encountered an equipment malfunction and the steps you took to troubleshoot and fix it.

- Describe how you optimized process parameters to improve efficiency or reduce downtime.

4. Emphasize Safety and Compliance

Safety and environmental compliance are paramount in chemical processing operations. Highlight your commitment to adhering to established protocols and regulations.

- Explain your understanding of the safety procedures specific to catalyst unit operations.

- Provide examples of your role in ensuring environmental compliance, such as monitoring emissions or managing waste disposal.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare questions that relate to the role, the company, or the industry.

- Inquire about the company’s plans for catalyst unit expansion or modernization.

- Ask about opportunities for professional development and training.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Catalyst Unit Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!