Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cathode Maker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cathode Maker so you can tailor your answers to impress potential employers.

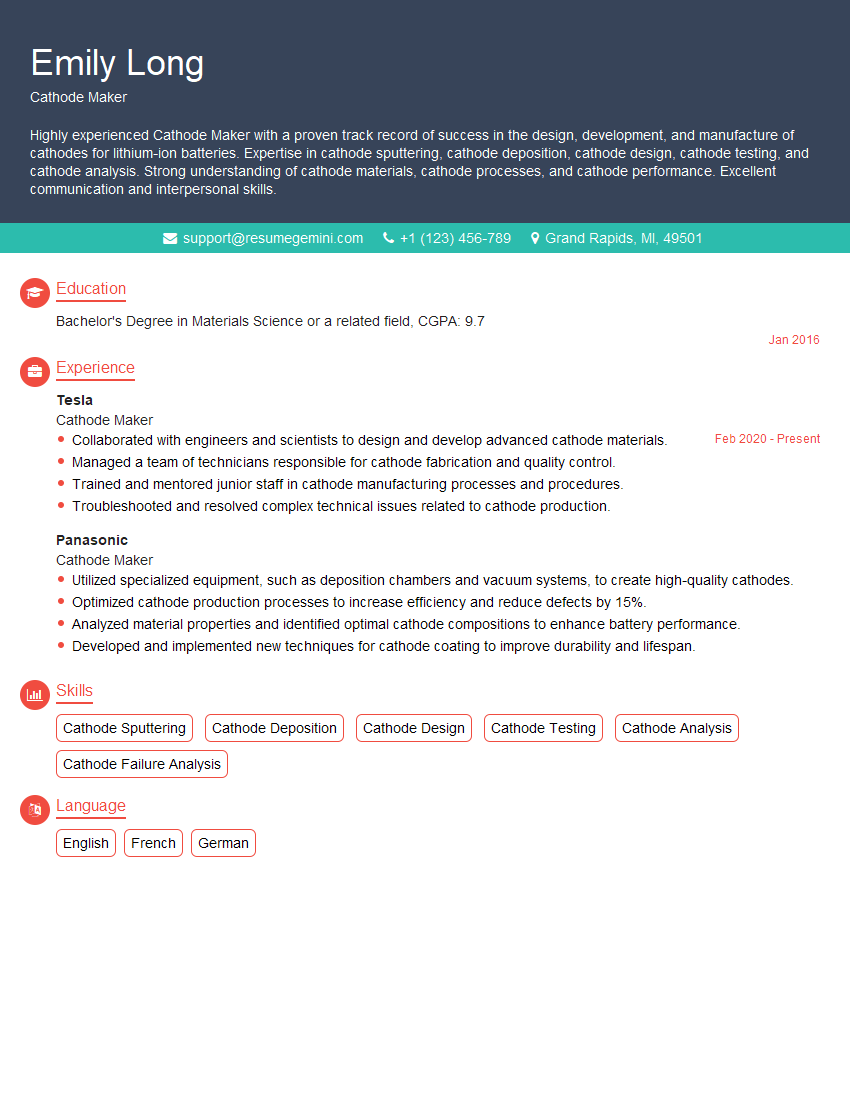

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cathode Maker

1. What is the importance of cathode in a battery?

- Cathode is a crucial component of a battery responsible for the following functions:

- Electrochemical reactions – Participate in electrochemical reactions during discharge, providing electrons to the external circuit

- Capacity – Determine the battery’s capacity and energy storage capabilities

- Structural integrity – Maintain the mechanical stability and integrity of the battery

- Cathode materials influence battery attributes such as voltage, power output, charge-discharge rates, cyclability, and safety

2. Explain the different types of cathode materials used in batteries.

Lithium-ion cathodes

- Lithium cobalt oxide (LiCoO2)

- Lithium nickel manganese cobalt oxide (NMC)

- Lithium iron phosphate (LiFePO4)

Sodium-ion cathodes

- Sodium iron phosphate (NaFePO4)

- Sodium nickel manganese oxide (NMO)

Other cathode materials

- Manganese dioxide (MnO2)

- Vanadium pentoxide (V2O5)

3. What are the desirable properties of cathode materials?

- High specific capacity – Store as much charge as possible

- High voltage – Contribute to higher battery voltage

- Good rate capability – Deliver high power output

- Long cycle life – Sustain high capacities over numerous charge-discharge cycles

- Thermal stability – Maintain stability under various temperature conditions

- Low cost – Economical to produce and implement

4. Describe the manufacturing process of cathode materials.

- Material preparation: Starting with raw materials, synthesis techniques are used to obtain the desired cathode material composition

- Calcination: Heating the material at high temperatures to induce solid-state reactions and crystal formation

- Grinding: Reducing the particle size to increase surface area and improve electrochemical performance

- Mixing: Combining cathode material with conductive agents and binders to form a slurry

- Coating: Applying the slurry onto a current collector (e.g., metal foil) and drying to form the cathode

5. What are the challenges in developing high-performance cathode materials?

- Structural stability: Maintaining the crystal structure and preventing degradation during charge-discharge cycling

- Capacity fading: Minimizing the loss of capacity over extended cycling

- Voltage instability: Controlling voltage drift and maintaining high voltage during cycling

- Cost-effectiveness: Developing cost-efficient materials that meet performance requirements

- Environmental considerations: Ensuring materials are environmentally friendly and pose minimal safety risks

6. What are the latest advancements in cathode material research?

- Novel materials: Exploring new materials beyond traditional compositions, such as layered oxides and polyanion compounds

- Doping and modification: Introducing dopants or modifying the surface of cathode materials to enhance performance

- Nanostructuring: Engineering cathode materials at the nanoscale to improve electrochemical kinetics

- Computational modeling: Utilizing simulations and modeling to understand and predict cathode behavior

7. How do you ensure the quality of cathode materials?

- Material characterization: Performing X-ray diffraction, scanning electron microscopy, and other techniques to analyze crystal structure, morphology, and composition

- Electrochemical testing: Conducting cyclic voltammetry, galvanostatic charge-discharge, and impedance spectroscopy to evaluate electrochemical performance

- Long-term cycling: Testing materials over extended cycles to assess capacity retention and cycle life

- Safety testing: Evaluating materials for thermal stability, flammability, and other safety concerns

8. Can you describe the role of a cathode maker in the battery supply chain?

- Material synthesis: Developing and optimizing processes for synthesizing high-quality cathode materials

- Quality control: Ensuring that produced materials meet performance and safety standards

- Collaboration with battery manufacturers: Partnering with battery manufacturers to provide customized cathode solutions

- Research and development: Continuously innovating and improving cathode materials to drive battery performance

9. What are the key industry trends in cathode material technology?

- High-energy cathodes: Developing materials with higher specific capacities for increased battery energy density

- Fast-charging cathodes: Improving rate capability to enable faster charging times

- Long-life cathodes: Extending cycle life to enhance battery durability

- Sustainable cathodes: Focusing on environmentally friendly materials and sustainable production processes

10. what is the future outlook for cathode material technology?

- Continued innovation: Ongoing research and development to push the boundaries of cathode performance

- Adoption of new technologies: Integration of novel materials and manufacturing techniques

- Demand driven by electrification: Growing demand for high-performance cathodes in electric vehicles and renewable energy storage

- Collaboration and partnerships: Strategic alliances between cathode makers, battery manufacturers, and research institutions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cathode Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cathode Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cathode Maker is responsible for the production of cathodes, which are essential components in various electronic devices. The key job responsibilities include:

1. Cathode Preparation

Ensuring the cathode’s preparation by cleaning, degreasing, and activating the substrate to improve adhesion.

- Operating vacuum deposition equipment to coat substrates with conductive materials.

- Monitoring and controlling coating parameters to achieve desired results.

2. Cathode Assembly

Assembling cathode components, including electrodes, insulators, and terminals, into a functional unit.

- Inspecting and testing cathode assemblies to ensure they meet quality standards.

- Performing repairs or modifications as necessary.

3. Cathode Testing

Conducting electrical and performance tests on cathodes to evaluate their functionality.

- Analyzing test results and identifying any defects or areas for improvement.

- Providing feedback to production teams to optimize cathode manufacturing processes.

4. Equipment Maintenance

Maintaining and calibrating equipment used in Cathode production, including vacuum deposition systems, testing equipment, and assembly tools.

- Following established maintenance schedules and procedures.

- Performing troubleshooting and resolving any equipment issues.

Interview Preparation Tips

To ace the interview for a Cathode Maker position, candidates can follow these preparation tips:

1. Research the Role and Company

Thoroughly research the specific Cathode Maker role and the company’s industry, products, and culture.

- Review the job description and identify the key requirements and responsibilities.

- Visit the company’s website and social media platforms to learn about their values and work environment.

2. Practice Your Technical Skills

Refresh your knowledge of cathode manufacturing processes, equipment, and testing methodologies.

- Practice explaining complex technical concepts and troubleshooting scenarios.

- Be prepared to discuss your experience with specific equipment and software used in Cathode production.

3. Showcase Your Problem-Solving Abilities

Highlight your problem-solving abilities and provide examples of how you have resolved technical challenges in previous roles.

- Describe a situation where you identified and addressed a manufacturing defect or equipment issue.

- Explain the steps you took to analyze the problem, develop solutions, and implement improvements.

4. Emphasize Your Attention to Detail

Cathode manufacturing requires precise execution and attention to detail. Emphasize your ability to work accurately and meticulously.

- Provide examples of your experience in following complex instructions and meeting precise quality standards.

- Explain how you ensure consistency and minimize errors in your work.

5. Prepare Questions for the Interviewer

Prepare insightful questions to ask the interviewer, demonstrating your interest in the role and the company.

- Inquire about the company’s commitment to quality and innovation in Cathode production.

- Ask about opportunities for professional development and advancement within the organization.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cathode Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.