Are you gearing up for a career in Caustic Cresylate Shift Superintendent? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Caustic Cresylate Shift Superintendent and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

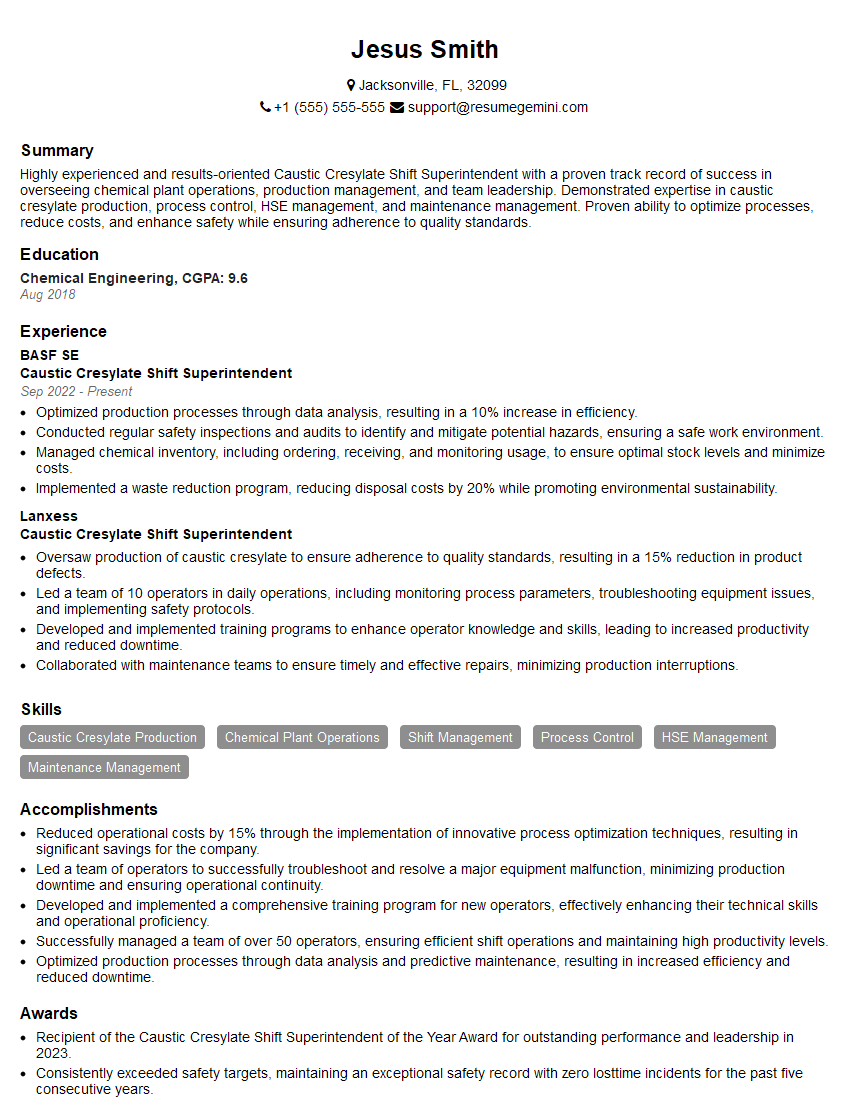

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Caustic Cresylate Shift Superintendent

1. What is the role of a Caustic Cresylate Shift Superintendent?

As a Caustic Cresylate Shift Superintendent, I will be responsible for the overall operation and supervision of the Caustic Cresylate production unit during my shift. This includes ensuring that the unit operates safely, efficiently, and in compliance with all applicable regulations and standards.

2. What are the key performance indicators (KPIs) for a Caustic Cresylate Shift Superintendent?

Production efficiency

- Volume of Caustic Cresylate produced per shift

- Yield of Caustic Cresylate relative to raw materials used

Product quality

- Meeting specifications for Caustic Cresylate purity and composition

- Minimizing the presence of impurities and contaminants

Safety

- Maintaining a safe work environment for all personnel

- Preventing accidents and incidents related to the production process

Environmental compliance

- Adhering to all applicable environmental regulations and standards

- Minimizing the environmental impact of the production process

3. What are the critical safety hazards associated with the production of Caustic Cresylate?

The production of Caustic Cresylate involves several critical safety hazards, including:

- Chemical hazards: Caustic Cresylate is a corrosive and toxic substance that can cause severe burns and eye damage. It is also flammable and can release toxic fumes when heated.

- Fire and explosion hazards: The production process involves the use of flammable materials, such as phenol and cresol. These materials can easily ignite and cause a fire or explosion.

- Pressure hazards: The production process involves the use of pressurized equipment, such as reactors and pipelines. These systems can fail and release high-pressure fluids, which can cause injury or damage to equipment.

4. What are the key maintenance activities required for a Caustic Cresylate production unit?

The key maintenance activities required for a Caustic Cresylate production unit include:

- Regular inspection and testing: All equipment and systems should be regularly inspected and tested to ensure they are in good working condition.

- Preventive maintenance: Regular maintenance tasks should be performed to prevent equipment failures and breakdowns.

- Corrective maintenance: When equipment failures or breakdowns occur, they should be promptly repaired to minimize downtime and maintain production efficiency.

5. How do you manage a team of operators in a Caustic Cresylate production unit?

To manage a team of operators in a Caustic Cresylate production unit, I would adopt the following strategies:

- Provide clear instructions and training: Ensure that all operators are fully trained and understand their roles and responsibilities.

- Communicate effectively: Maintain open communication with operators to share information, provide feedback, and address any concerns.

- Foster teamwork: Encourage cooperation and collaboration among operators to promote a positive and productive work environment.

- Delegate responsibility: Empower operators to take ownership of their tasks and decision-making.

- Recognize and reward performance: Acknowledge and reward operators for their contributions and achievements.

6. How do you troubleshoot and resolve production problems in a Caustic Cresylate production unit?

To troubleshoot and resolve production problems in a Caustic Cresylate production unit, I would follow a systematic approach:

- Identify the problem: Gather information about the problem, including when it occurred, what symptoms are present, and what actions have been taken.

- Analyze the problem: Consider possible causes of the problem and develop hypotheses.

- Develop and implement solutions: Test hypotheses and implement solutions to resolve the problem.

- Monitor and evaluate the solution: Track the effectiveness of the solution and make adjustments as needed.

7. What are the latest trends and developments in the production of Caustic Cresylate?

The production of Caustic Cresylate is undergoing several trends and developments, including:

- Process optimization: The use of advanced technologies and techniques to improve the efficiency and yield of the production process.

- Sustainability: The adoption of environmentally friendly practices and technologies to reduce the environmental impact of the production process.

- Product innovation: The development of new grades and formulations of Caustic Cresylate to meet changing market demands.

8. What is the difference between Caustic Cresylate and Sodium Cresylate?

Caustic Cresylate and Sodium Cresylate are both derivatives of cresol, but they have different chemical structures and properties.

- Caustic Cresylate: A mixture of sodium cresylate and cresol, which is a corrosive and toxic substance. It is used as a disinfectant and a preservative.

- Sodium Cresylate: A salt of cresol and sodium hydroxide, which is a less corrosive and less toxic substance. It is used as a disinfectant and a herbicide.

9. What are the applications of Caustic Cresylate?

Caustic Cresylate has a variety of applications, including:

- Disinfectant: It is used to kill bacteria and viruses on surfaces and in water.

- Preservative: It is used to prevent the growth of bacteria and fungi in wood, leather, and other materials.

- Herbicide: It is used to kill weeds and unwanted vegetation.

- Industrial cleaner: It is used to clean and degrease machinery and equipment.

10. What are the safety precautions that should be taken when working with Caustic Cresylate?

When working with Caustic Cresylate, it is important to take the following safety precautions:

- Wear protective clothing: Wear gloves, goggles, and a respirator to protect your skin, eyes, and lungs.

- Handle with care: Avoid contact with Caustic Cresylate and do not ingest or inhale it.

- Work in a well-ventilated area: Ensure that there is adequate ventilation to prevent the buildup of toxic fumes.

- Store properly: Store Caustic Cresylate in a cool, dry place, away from heat and direct sunlight.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Caustic Cresylate Shift Superintendent.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Caustic Cresylate Shift Superintendent‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Caustic Cresylate Shift Superintendent is responsible for the overall operation of the Caustic Cresylate plant, ensuring that production meets quality standards, safety regulations, and environmental guidelines.

1. Production Management

Ensuring that the plant meets production targets. Oversaw all stages of cresylate production, from raw material preparation to finished product packaging.

- Scheduling and coordinating production processes.

- Monitoring production equipment and making necessary adjustments.

- Maintaining production records and reports.

2. Quality Control

Establishing and maintaining quality control standards for the production of caustic cresylate. Developed and implemented a comprehensive quality control program that ensured the product met all specifications.

- Conducting quality control tests and inspections.

- Identifying and correcting quality problems.

- Working with the Quality Assurance department to ensure compliance with regulations.

3. Safety Management

Ensuring that the plant operates in a safe and healthy manner. Implemented safety procedures and trained employees on safety protocols.

- Developing and implementing safety policies and procedures.

- Conducting safety inspections and audits.

- Investigating accidents and incidents.

4. Environmental Management

Ensuring that the plant complies with all environmental regulations. Guided the plant towards achieving zero waste and reducing environmental impact.

- Developing and implementing environmental management plans.

- Monitoring environmental performance and reporting results.

- Identifying and mitigating environmental risks.

Interview Tips

To help candidates ace the interview for this role, here are some essential preparation tips and interview hacks:

1. Research the Company and the Role

Familiarize yourself with the company’s background, its values, and its products or services. Understand the specific responsibilities of the Caustic Cresylate Shift Superintendent role and how it aligns with your skills and experience.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay updated on trends and best practices.

2. Practice Answering Common Interview Questions

Prepare thoughtful answers to common interview questions, such as:

- Tell me about yourself and your experience.

- Why are you interested in this role?

- What are your strengths and weaknesses?

- How do you handle conflict in the workplace?

- What are your salary expectations?

3. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible using specific metrics or data points.

- Use the STAR method (Situation, Task, Action, Result) to describe your experiences.

- Provide examples of how you have successfully managed production, ensured quality, maintained safety, and complied with environmental regulations.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare a few questions that will help you gain a deeper understanding of the role, the company, and the interviewer’s perspective.

- What are the key challenges and opportunities facing the Caustic Cresylate plant?

- How does the company prioritize safety and environmental sustainability?

- What is the company’s growth strategy for the future?

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Caustic Cresylate Shift Superintendent, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Caustic Cresylate Shift Superintendent positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.